304 & 316 Stainless Steel Sanitary Elbows and Tees

Manufactured to the highest hygienic standards, our 304 & 316 Stainless Steel Sanitary Elbows and Tees represent the pinnacle of clean process piping technology for industries where purity and contamination control are critical. These fittings, crafted from premium AISI 304 or superior corrosion-resistant 316/316L stainless steel, are designed specifically for sanitary and aseptic processes in food, beverage, dairy, pharmaceutical, biotechnology, and cosmetic manufacturing.

Engineered for smooth, crevice-free internal surfaces and easy cleaning (CIP/SIP), these fittings comply with stringent standards such as ASME BPE (Bioprocessing Equipment) and 3-A Sanitary Standards. Available in multiple connection types like sanitary clamp (Tri-Clamp®) and orbital butt weld, they ensure leak-tight seals while preventing bacterial harborage. Their exceptional corrosion resistance and polished finishes guarantee product integrity, operational reliability, and compliance with global food safety and pharmaceutical regulations.

Data sheet

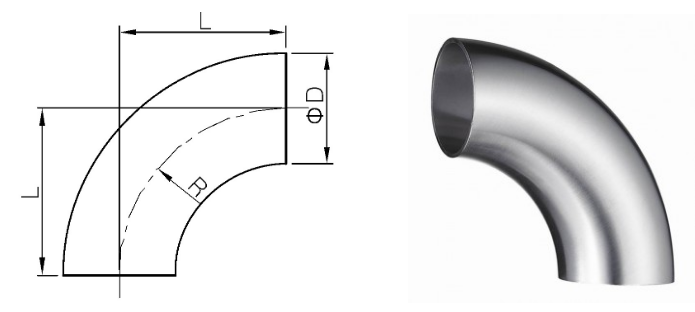

Dimension of Sanitary Weld Elbow 90 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1/1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

Dimension of Sanitary Weld elbow 90 degree -DIN (Unit:mm)

| SIZE | D | L | R |

| DN10 | 12 | 26 | 26 |

| DN15 | 18 | 35 | 35 |

| DN20 | 22 | 40 | 40 |

| DN25 | 28 | 50 | 50 |

| DN32 | 34 | 55 | 55 |

| DN40 | 40 | 60 | 60 |

| DN50 | 52 | 70 | 70 |

| DN65 | 70 | 80 | 80 |

| DN80 | 85 | 90 | 90 |

| DN100 | 104 | 100 | 100 |

| DN125 | 129 | 187 | 187 |

| DN150 | 154 | 225 | 225 |

| DN200 | 204 | 300 | 300 |

Dimension of Sanitary Weld elbow 90 degree -ISO/IDF (Unit:mm)

| SIZE | D | L | R |

| 12.7 | 12.7 | 19.1 | 19.1 |

| 19 | 19.1 | 28.5 | 28.5 |

| 25 | 25.4 | 33.5 | 33.5 |

| 32 | 31.8 | 38 | 38 |

| 38 | 38.1 | 48.5 | 48.5 |

| 45 | 45 | 57.5 | 57.5 |

| 51 | 50.8 | 60.5 | 60.5 |

| 57 | 57 | 68 | 68 |

| 63 | 63.5 | 83.5 | 83.5 |

| 76 | 76.2 | 88.5 | 88.5 |

| 89 | 89 | 103.5 | 103.5 |

| 102 | 101.6 | 127 | 127 |

| 108 | 108 | 152 | 152 |

| 114.3 | 114.3 | 152 | 152 |

| 133 | 133 | 190 | 190 |

| 159 | 159 | 228.5 | 228.6 |

| 204 | 204 | 300 | 300 |

| 219 | 219 | 305 | 302 |

| 254 | 254 | 372 | 375 |

| 304 | 304 | 450 | 450 |

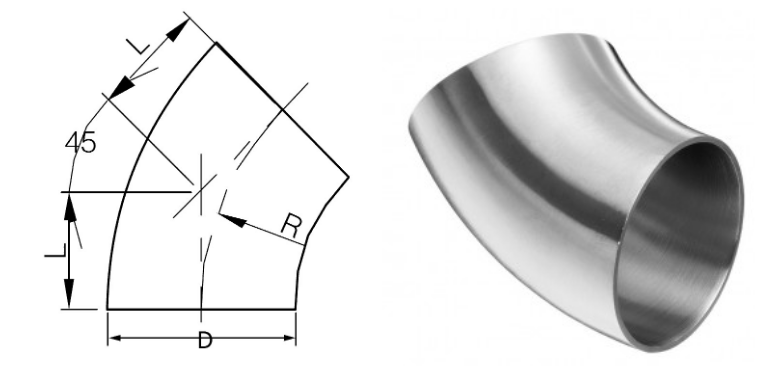

Dimension of Santitary Weld Elbow-45 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 7.9 | 19.1 |

| 3/4" | 19.1 | 11.8 | 28.5 |

| 1" | 25.4 | 15.8 | 38.1 |

| 1 1/4" | 31.8 | 69.7 | 47.7 |

| 1 1/2" | 38.1 | 74.1 | 57.2 |

| 2" | 50.8 | 103.2 | 76.2 |

| 2 1/2" | 63.5 | 131.8 | 95.3 |

| 3" | 76.2 | 160.3 | 114.3 |

| 4" | 101.6 | 211.1 | 152.4 |

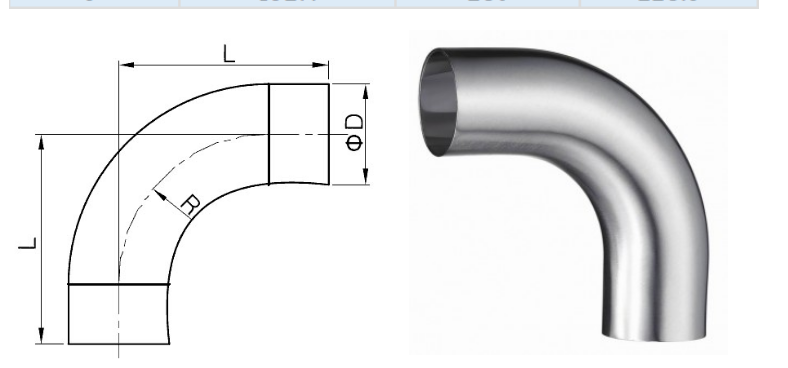

Dimension of Santitary Weld Elbow-90 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1 1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

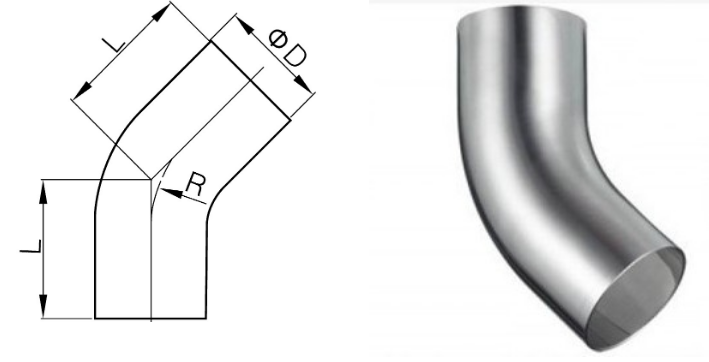

Dimension of Santitary Weld Elbow-45 degree With Straight Ends -SMS(Unit:mm)

| SIZE | D | L | R |

| 25 | 25.4 | 45 | 25 |

| 32 | 31.8 | 53.3 | 32 |

| 38 | 38.1 | 56.7 | 38 |

| 51 | 50.8 | 63.6 | 51 |

| 63 | 63.5 | 80.8 | 63.5 |

| 76 | 76.2 | 82 | 76 |

| 102 | 101.6 | 108.9 | 150 |

CHECKING

Product Detailed Description

Material Excellence:

Fittings are precision fabricated from certified AISI 304 or 316/316L austenitic stainless steel. Grade 304 offers excellent general corrosion resistance, while Grade 316, with its added molybdenum (2-3%), provides superior resistance to chlorides and pitting, making it ideal for harsh cleaning chemicals and marine-influenced environments. All materials are sourced with full traceability and mill certification to ensure compliance with FDA and regulatory requirements for contact with consumable products.

Sanitary Design & Manufacturing:

Every fitting is designed with zero dead legs, smooth radii, and fully recess-free internal surfaces to meet the most demanding hygienic standards. Manufacturing involves precision CNC machining and forming, followed by extensive polishing processes. The internal surface undergoes sequential grit polishing (typically up to 320 grit or finer) to achieve a specified Ra (Roughness Average) value. Electropolishing is available as a final step to further reduce surface roughness, enhance corrosion resistance, and create a passive chromium oxide layer.

Packing and Shipping

Clean Room Packaging:

After final inspection and cleaning, fittings are packaged in a controlled environment (ISO Class 7 or better). Each fitting is individually bagged in medical-grade, static-dissipative polyethylene bags that are heat-sealed. Bags are often flushed with inert gas (Nitrogen) to prevent oxidation during storage and transit.

Protective & Hygienic Packaging:

Individually bagged fittings are placed in double-walled corrugated cartons with internal dividers to prevent contact and abrasion. For international shipments, cartons are secured on pallets and wrapped with clean polyethylene stretch film. All packaging materials are non-shedding and lint-free.

Marking & Documentation:

External cartons are clearly labeled with product details, grade, finish, lot number, and handling instructions ("Sanitary - Keep Clean"). Shipping documentation includes a Packing List, Commercial Invoice, Certificate of Origin, Material Certificates, and all relevant Test Reports.

Shipping Logistics:

We utilize logistics partners experienced in handling high-purity components. Shipping modes include air freight for expedited delivery and sea freight for bulk orders. We ensure all customs documentation highlights the sanitary nature of the goods for appropriate handling.

Critical Industry Applications

Critical Industry Applications

Food & Beverage:

Processing lines for dairy, beer, juice, and sauces; CIP systems; ingredient transfer.

Pharmaceutical & Biotech:

Purified Water (PW) and Water-for-Injection (WFI) distribution, bioreactor feed lines, product transfer, and clean utility systems.

Cosmetics & Personal Care:

Manufacture of creams, lotions, and other sensitive products requiring hygienic transfer.

Semiconductor:

High-purity chemical and ultrapure water (UPW) distribution in fabrication plants.

Q: Can you accept TPI?

A: Yes, sure. Welcome visit our factory and come here to inspect the goods and inspect production process.

Q: Can you supply Form e, Certificate of origin?

A: Yes, we can supply.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you accept L/C deferred 30, 60, 90 days?

A: We can. Please negotiate with sales.

Q: Can you accept O/A payment?

A: We can. Please negotiate with sales.

Q: Can you supply samples?

A: Yes, some samples are free, please check with sales.

Q: Can you supply the products which comply with NACE?

A: Yes, we can.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

carbon steel concentric reducer astm a105 Black...

-

304 316 Stainless Hygienic Pneumatic Actuated B...

-

8 Inch stainless steel pipe cap pipe end cap he...

-

304 316 fitting connection Forged Swage Nipple

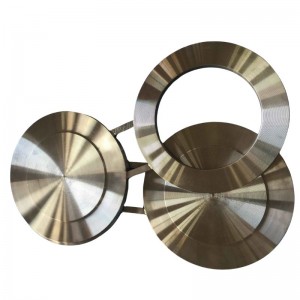

-

ASME b16.48 Factory Sale carbon steel figure 8 ...

-

Stainless steel long bend1d 1.5d 3d 5d radius 3...