CL150 CL300 Paddle Spacer Plank Flange Spectacle Blind Figure 8

The ASME B16.48 Paddle Spacer Plank Flange Spectacle Blind Figure 8 represents a critical safety and isolation component in industrial piping systems. This integrated assembly combines three essential functions - blind flange, spacer, and spectacle blind - into a single, precisely engineered device. Manufactured in strict compliance with ASME B16.48 standards for blinds and spacers, this component ensures safe isolation, positive shut-off, and reliable system separation in Class 150 and 300 pressure ratings.

SPECIFICATION

| Product Name | Blind flange |

| Size | 1/2"-250" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti,

317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

DIMENSION STANDARDS

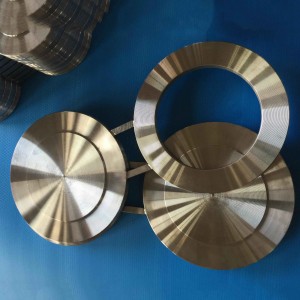

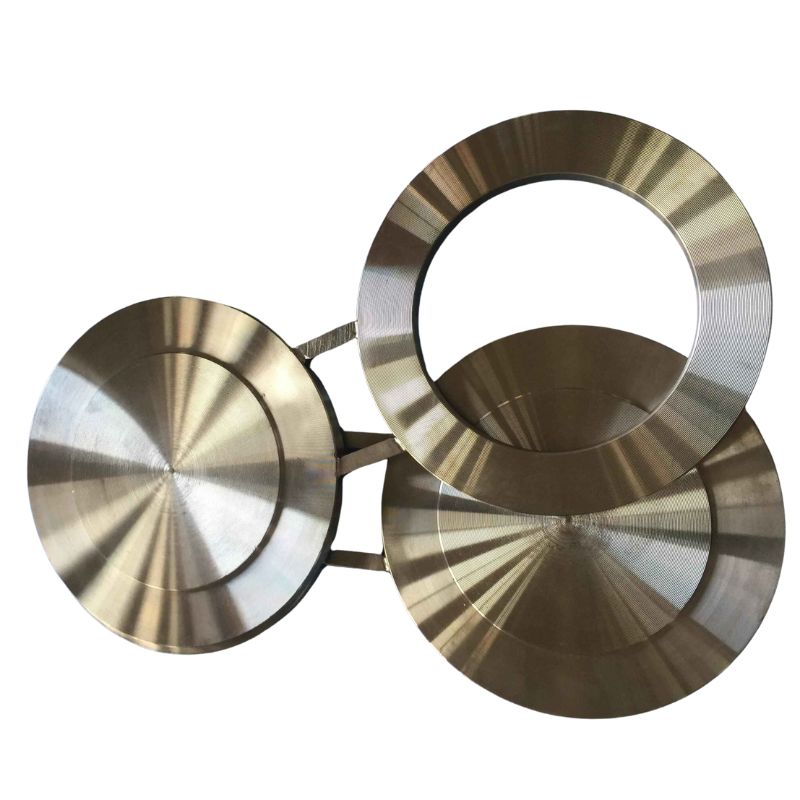

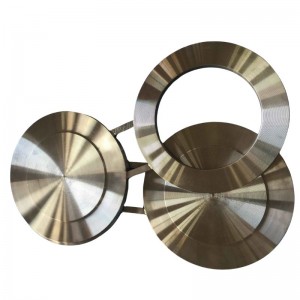

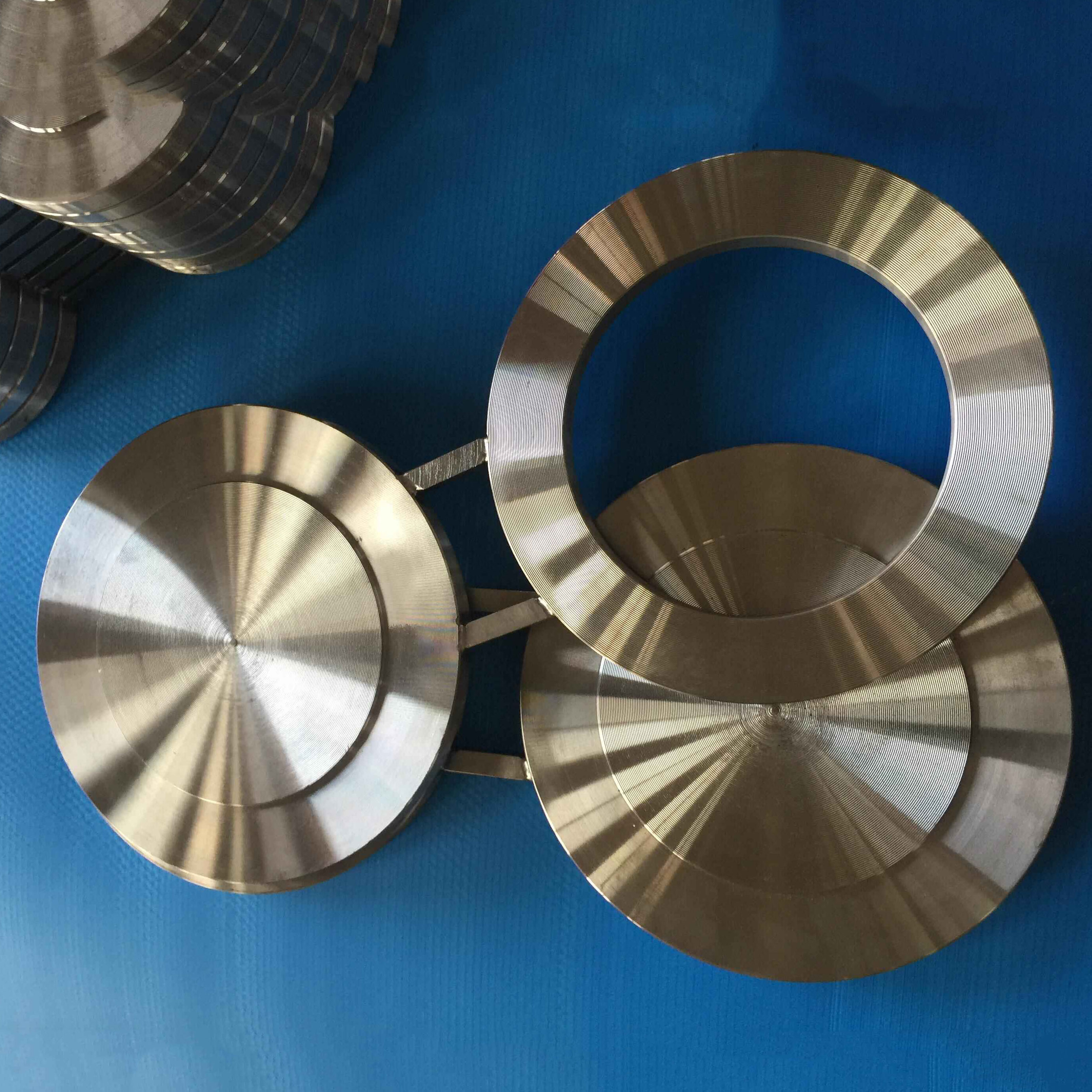

PRODUCTS DETAIL SHOW

1.Spectacle Blind Configuration

One solid end (blind plate) for complete isolation

One open end (spacer ring) for flow through

Rotatable design for operational flexibility

Clearly visible position indication

2.Paddle Spacer Feature

Flat, paddle-shaped handle for easy identification and operation

Extended length for safe handling during hot work permits

Standard thickness per ASME B16.48 requirements

Reinforced construction for durability

3.Paddle Spacer Feature

Designed to fit between standard ASME B16.5 flanges

Matches drilling patterns and dimensions exactly

Available for raised face (RF) and ring-type joint (RTJ) flanges

Proper alignment through precision machining

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

Product introduction

The ASME B16.48 Class 150/300 Paddle Spacer Plank Flange Spectacle Blind Figure 8 represents an essential component for safe and reliable piping system isolation. Through precision manufacturing, strict quality control, and comprehensive testing, we ensure each unit meets the highest standards of performance and reliability. Our commitment to excellence, combined with decades of industry experience, makes these components the preferred choice for engineers and operators worldwide who demand safety, reliability, and compliance in their critical isolation applications.

We manufacture precision-engineered spectacle blind flanges compliant with ASME B16.48 standards for Class 150 and 300 pressure ratings. These critical safety components, commonly known as "figure-8 blinds" or "spectacle blinds," provide positive isolation in piping systems through their unique dual-plate design – featuring one solid blind plate and one open spacer plate connected by a central web. The integrated paddle handle ensures clear visual identification of position and facilitates safe operation during system isolation and maintenance procedures.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.