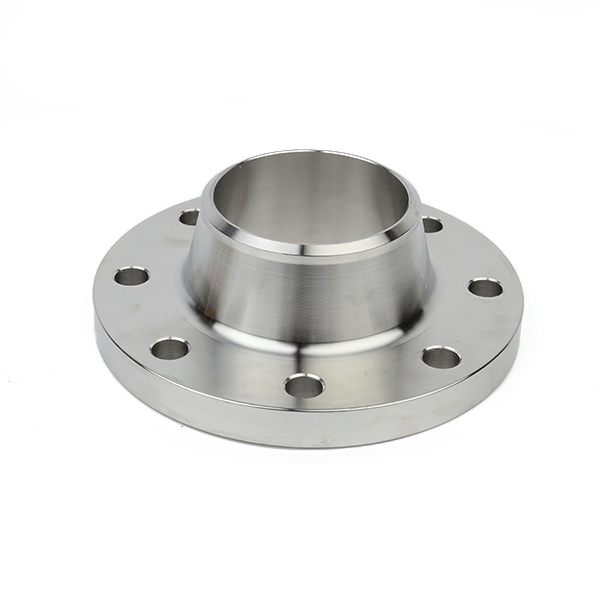

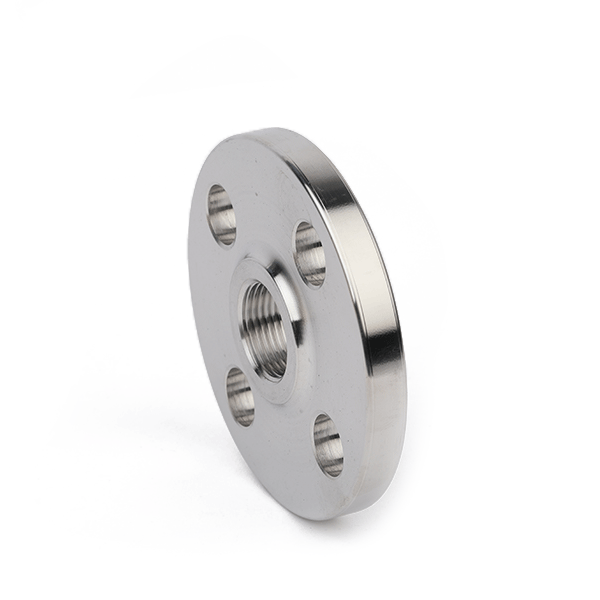

Best Cheap Weld Neck Flange Factories – Forged Threaded Flange – C. Z. IT Detail:

SPECIFICATION

| Product Name | Thread flange |

| Size | 1/2″-24″ |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5,EN1092-1, JIS B2220 etc. |

| Threaded type | NPT ,BSP |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

DIMENSION STANDARDS

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

COOPERATION CASE

This project for Brazil project. Some items need anti-rust oil and some item need galvanized coating.

Product detail pictures:

Related Product Guide:

What are duplex stainless steel applications?

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for Best Cheap Weld Neck Flange Factories – Forged Threaded Flange – C. Z. IT, The product will supply to all over the world, such as: Uganda, Tunisia, Greece, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.