Precision Engineered Stainless Steel & High-Performance Alloy Pipes

We produce an extensive selection of industrial pipes utilizing various manufacturing processes to meet diverse application requirements.

Our product line includes seamless, electric resistance welded (ERW), electric fusion welded (EFW), and double submerged arc welded (DSAW) pipes, manufactured to strict international standards including API 5L, ASTM A312, and ASME B36.10M.

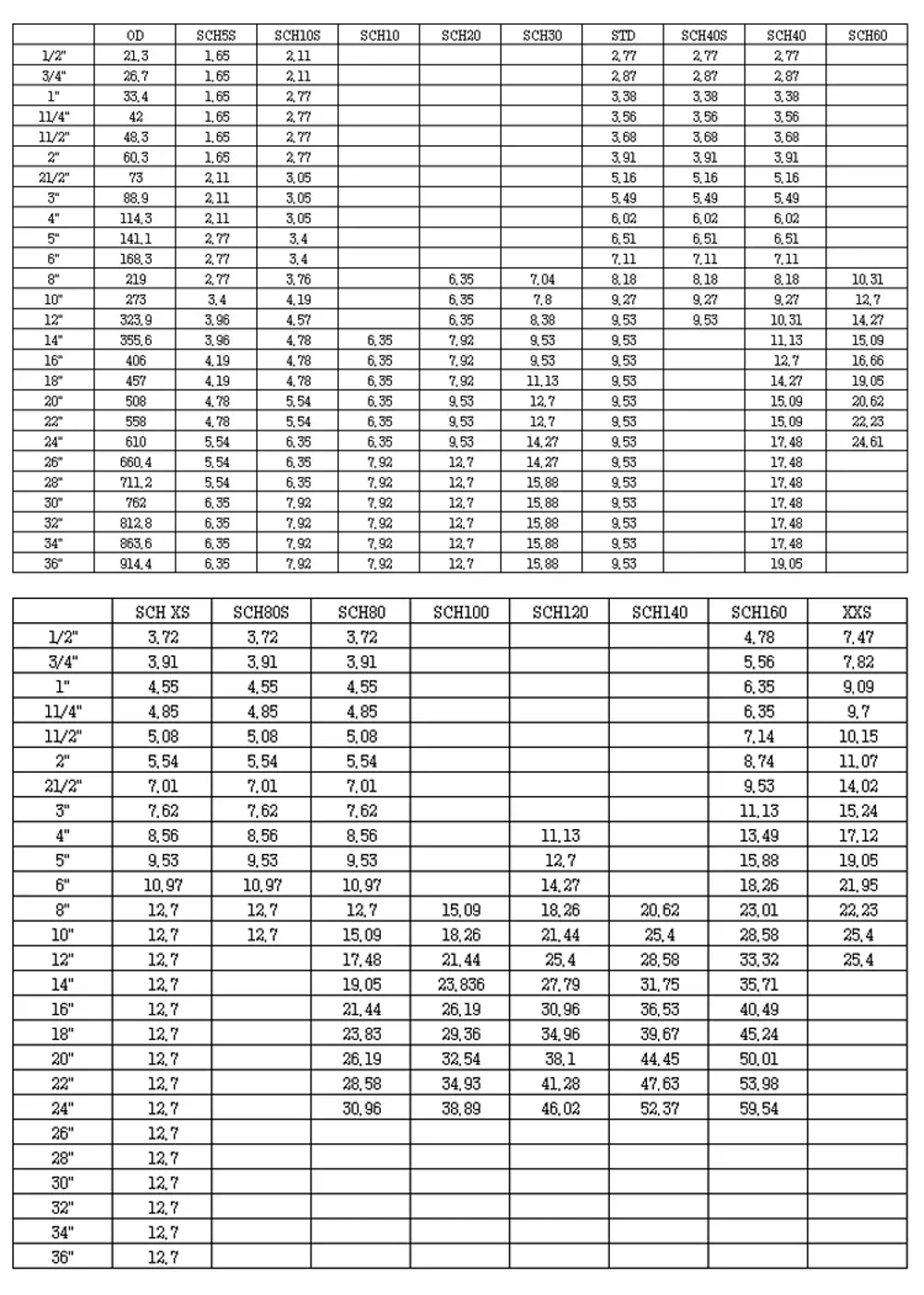

Product parameters

| Product name | seamless pipes, ERW pipe,EFW pipe, DSAW pipes. |

| Standard | ASME B36.10M, API 5L, ASTM A312, ASTM A213. ASTM A269, etc |

| Material | stainless steel: 304, 316, 317, 904L, 321, 304h, 316ti, 321H, 316H, 347, 254Mo, 310s, etc. |

| Super duplex steel:s31803,s32205, s32750,s32760, 1.4462, 1.4410, 1.4501, etc. | |

| Nickel alloy:inconel600, inconel 625, inconel 718, incoloy 800, incoloy 825, C276,

alloy 20, Monel 400, alloy 28 etc. |

|

| OD | 1mm-2000mm , customized. |

| Wall thickness | SCH5S SCH10S, SCH10, SCH20,SCH30, SCH40S, STD, SCH40, SCH80S, SCH80, XS, SCH60,

SCH100, SCH120,SCH140,SCH160,XXS, customized , etc |

| Length | 5.8m, 6m, 11.8m, 12m, SRL, DRL, or as required |

| Surface | Annealing, pickling, polishing, bright, sand blast,hair line, brush, satin, snow sand, titanium, etc |

| Application | Stainless steel pipe widely used in petroleum,chemical industry,electric power, boiler,high temperature resistant,

low temperature resistant, corrosion resistant., sour service, etc. |

| The size of the pipes can be made according to clients requirements. | |

| Contacts | If you have any questions, please feel free to contact me.we are sure your inquiry or requirements will get prompt attention. |

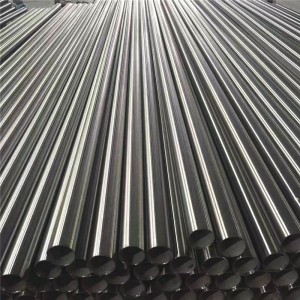

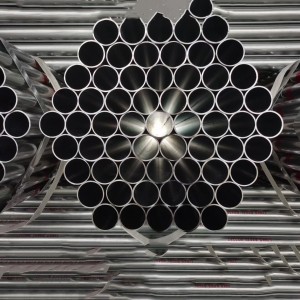

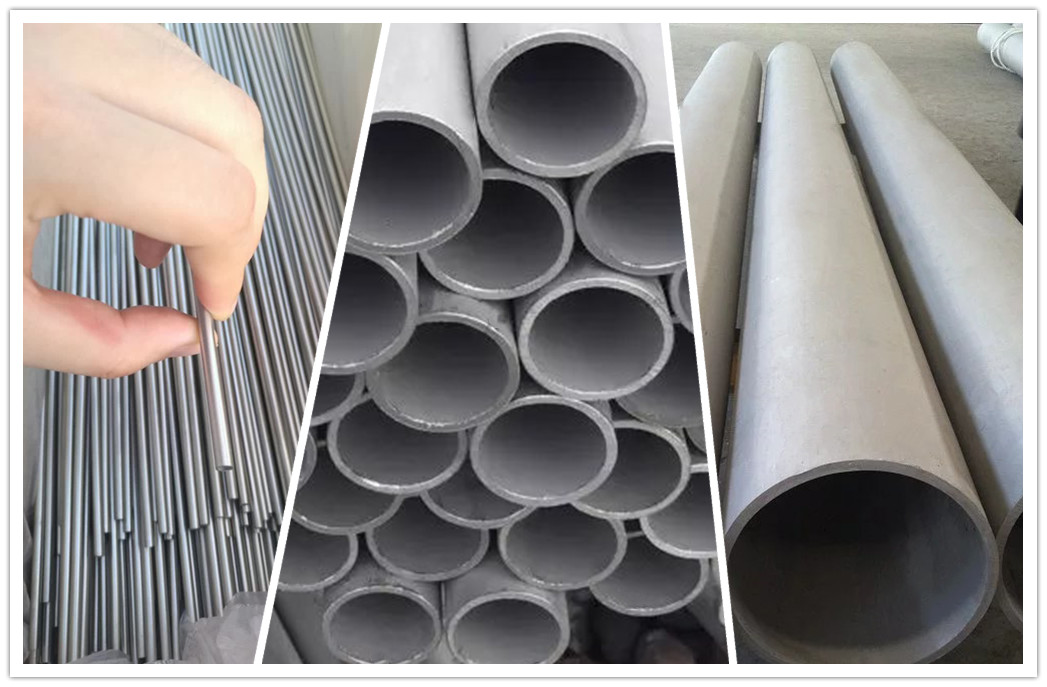

Detailed photos

1. Surface can be pickled, matt finished, polished, Mirror polished

2. End can be bevel end or plain end

3. length can be on request, customized.

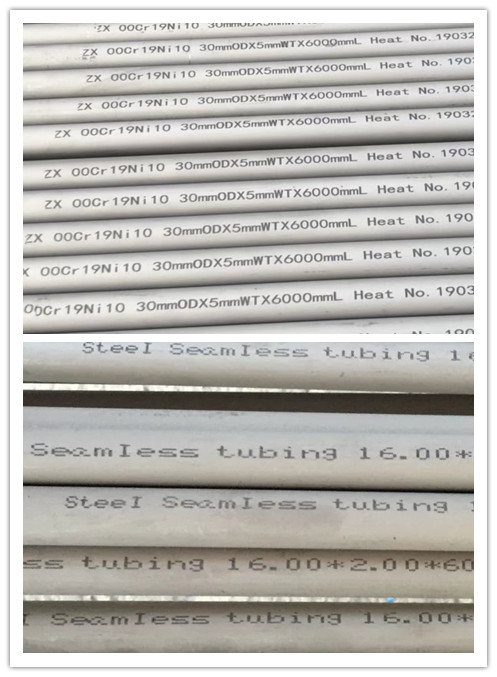

Marking

Printed marking on request. OEM is accepted.

With extensive experience in industrial pipe manufacturing, we have established ourselves as a reliable partner for global clients.

Our production facilities incorporate advanced machining equipment and quality control systems, enabling us to maintain consistent product quality across all material grades and specifications.

The company's technical team possesses deep expertise in material science and production processes, ensuring optimal product selection and performance for specific application requirements.

specification

Stainless steel pipe

Packaging & Shipping

1. End will be protected by plastic caps.

2. Smaller tubes are packed by plywood case.

3. Bigger pipes are packed by bundling.

4. All package, we will put packing list.

5. Shipping marks on our request.

Inspection

1. PMI, UT test, PT test.

2. Dimension test.

3. Supply MTC, inspection certificate, EN10204 3.1/3.2.

4. NACE certificate, sour service

Before delivery, our QC team will arrange NDT test and dimension inspection.

Also accept TPI(third party inspection).

We implement rigorous quality assurance procedures throughout the manufacturing process. Each production batch undergoes multiple inspection stages including:

- Chemical composition verification

- Mechanical property testing

- Dimensional accuracy checks

- Non-destructive examination

- Surface quality assessment

Our testing laboratories are equipped to perform comprehensive evaluations according to project specifications and international standards, with full documentation and material traceability provided.

Global Supply Chain & Logistics

We maintain efficient supply chain management to ensure reliable delivery worldwide. Our capabilities include:

- Flexible production scheduling

- Strategic inventory management

- Export-standard packaging

- Global logistics coordination

This infrastructure enables us to serve clients across multiple time zones with consistent reliability and responsive service.

Product description

Alloy tube is a kind of seamless steel pipe, alloy tube is divided into structural seamless tube and high pressure heat resistant alloy tube. It is mainly different from the production standard of alloy tube and its industry, and the alloy tube is annealed and tempered to change its mechanical properties. To achieve the required processing conditions. Its performance is higher than the general seamless steel pipe variable utilization value, the chemical composition of the alloy pipe contains more Cr, high temperature resistance, low temperature resistance, corrosion resistance. General carbon seamless pipe does not contain alloy composition or alloy composition is very little, alloy pipe in petroleum, aerospace, chemical, electric power, boiler, military and other industries used more widely because the mechanical properties of alloy tube change better adjustment.

The alloy pipe has a hollow cross-section and is widely used as a pipeline for conveying fluids, such as pipelines for conveying oil, natural gas, gas, water, mechanical processing, and some solid materials. Compared with solid steel such as round steel, the bending and torsional strength is the same, the weight is lighter, alloy steel pipe is an economic cross-section of steel, widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipe, automobile transmission shaft, bicycle frame and construction of steel scaffolding. The manufacture of ring parts with alloy steel pipes can improve the utilization rate of materials, simplify the manufacturing process, save materials and processing hours, such as rolling bearing rings, jack sleeves, etc., which have been widely used to manufacture steel pipes. Alloy steel pipe is an indispensable material for all kinds of conventional weapons, and the barrel and barrel of the gun must be made of steel pipe. Alloy steel pipes can be divided into round tubes and special-shaped tubes according to the different shapes of the cross-sectional area. Since the circle area is the largest when the circumference is equal, more fluid can be transported with a circular tube. In addition, when the annular section is subjected to internal or external radial pressure, the force is more uniform, so the vast majority of steel pipes are round pipes.

Alloy pipe has large diameter alloy pipe, thick wall alloy pipe, high pressure alloy pipe, alloy flange, alloy elbow, P91 alloy pipe and seamless steel pipe, in addition to fertilizer special pipe is also very common.

Industry Compliance & Certification

Our products comply with major international standards and certification requirements, including but not limited to:

- ISO 9001 quality management

- PED compliance for European markets

- NACE MR0175 for sour service applications

We maintain updated certification and can provide necessary documentation for regulatory compliance in various markets.

FAQ

1. What is 304 round stainless steel pipe seamless white steel pipe?

304 round stainless steel pipe seamless white steel pipe is a cylindrical pipe made of 304 grade stainless steel, seamless and with a white surface.

2. What is the difference between seamless steel pipe and welded steel pipe?

Seamless steel pipes are manufactured without any welds and have a smoother and more uniform surface. Welded steel pipe is made by welding two or more sections of steel together.

3. What are the benefits of using grade 304 stainless steel?

Grade 304 stainless steel is highly corrosion-resistant, making it suitable for a variety of applications. It also offers excellent strength and durability, good heat resistance, and is easy to clean and maintain.

4. What are the common uses of 304 round stainless steel pipe and seamless white steel pipe?

These pipes are commonly used in industries such as food processing, pharmaceutical, chemical, petrochemical, and construction. They can be used to transport fluids, gases and solids as well as in structural applications.

5. Can 304 round stainless steel pipe seamless white steel pipe be used for outdoor applications?

Yes, grade 304 stainless steel is suitable for outdoor applications as it resists corrosion caused by exposure to moisture, chemicals, and harsh weather conditions.

6. What is the maximum temperature that 304 round stainless steel pipe seamless white steel pipe can withstand?

Grade 304 stainless steel has a maximum operating temperature of approximately 870°C (1600°F), making it suitable for high temperature applications.

7. How to ensure the quality of 304 round stainless steel seamless white steel pipe?

The quality of these pipes is ensured through various tests and inspections, including chemical composition analysis, mechanical testing, dimensional inspection, and non-destructive testing methods such as ultrasonic testing.

8. Can the size and length of 304 round stainless steel seamless white steel pipe be customized?

Yes, these tubes can be customized to specific requirements in terms of size, length and even surface finish. Customization options are available to meet the diverse needs of different applications.

9. How should 304 round stainless steel seamless white steel pipes be stored?

To ensure proper storage, these tubes should be kept in a dry and clean environment, preferably indoors. They should be protected from moisture, chemicals and physical damage during storage.

10. Are there any certifications for 304 round stainless steel seamless white steel pipes?

Yes, reputable manufacturers can provide certifications such as Material Test Reports (MTR), Factory Test Certificates (MTC) and Certificates of Compliance to ensure product quality and traceability.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

Best Cheap Stainless Steel Coupling Pricelist &...

-

Metal Incoloy 825 Nickel Alloy Pipe Seamless Fo...

-

Hot Dip Galvanized 6 Inch Sch 40 A179 Gr.B Roun...

-

Hastelloy C276 400 600 601 625 718 725 750 800 ...

-

JIS Inconel600 Incoloy800h Inconel 625 Seamless...

-

Nickel incoloy 800 800H 825 inconel 600 625 690...

.jpg)

-300x300.jpg)