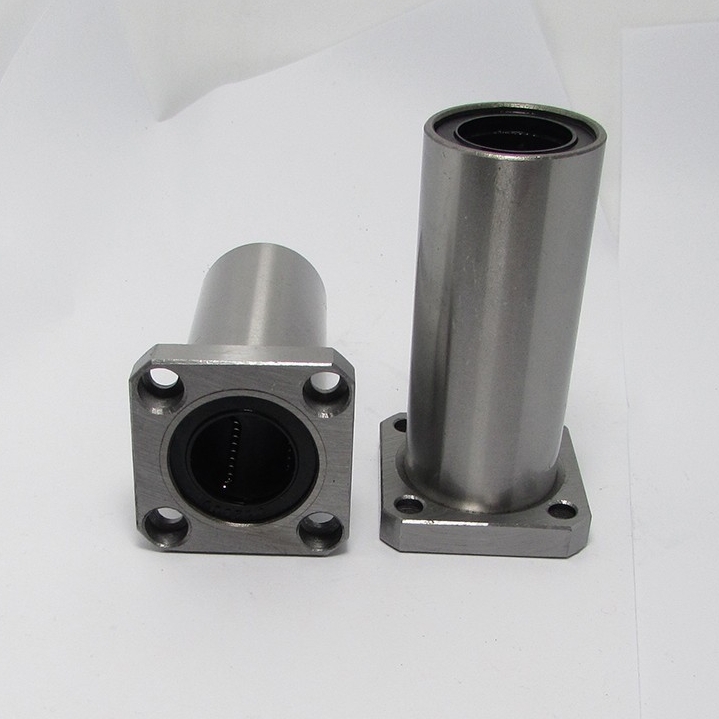

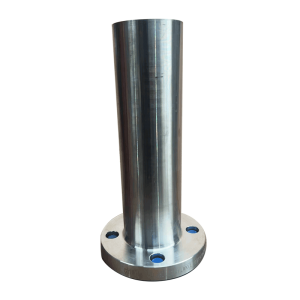

Customized Flange ANSI/ASME/JIS Standard Steel Flange

We specialize in manufacturing customized flanges that meet ANSI, ASME, and JIS standards, available in carbon steel, stainless steel, and square flange designs. Our flanges are engineered to provide reliable performance across various industrial applications, with complete customization options to meet specific project requirements and dimensional specifications.

Design & Engineering Customization

Flange Types: Custom designs for weld neck, slip-on, blind, socket weld, lap joint, threaded, and special configurations

Dimensions: Non-standard diameters, thicknesses, and bolt circle configurations

Pressure Ratings: Custom pressure classes beyond standard ratings

Face Types: Special facing requirements including raised face, flat face, ring joint, and tongue-and-groove

Integral Features: Added features like lugs, tabs, or special connections

Quality Assurance

Material traceability with mill certificates

Dimensional verification per specified standards

Non-destructive testing reports

Pressure testing certification

Full documentation package

Manufacturing Capabilities

Custom Machining:

CNC precision machining for special dimensions

Heat Treatment:

Normalizing, quenching, tempering as required

Surface Treatment:

Anti-rust oil, galvanizing, painting, coating

Testing Facilities:

UT, MT, PT, RT, hydrostatic testing

Certification:

ISO 9001, PED, API 6A, ABS, DNV-GL

MARKING AND PACKING

Standard export packaging

Wooden cases or pallets

Plastic protection for machined surfaces

Clear marking and identification

Worldwide shipping arrangements

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

Manufacturing Process Customization

Forging Methods: Custom die designs for specific flange geometries

Heat Treatment: Tailored thermal processes for desired mechanical properties

Machining: Special tolerances, surface finishes, and geometric features

Welding Preparation: Custom bevel designs and welding preparations

Application

Oil & Gas: Wellhead flanges, subsea components, sour service applications

Power Generation: Nuclear-grade flanges, high-temperature applications

Chemical Processing: Corrosion-resistant designs for aggressive media

Marine & Offshore: Saltwater-resistant materials and coatings

Aerospace: Precision flanges with strict tolerances

Why Choose Our Customized Flanges?

Technical Expertise: 30+ years in custom flange manufacturing

Quality Commitment: Stringent quality control throughout production

Flexible Capacity: Ability to handle both small and large custom orders

Global Experience: Successful projects worldwide across multiple industries

Competitive Advantage: Cost-effective solutions without compromising quality

Q: Can you accept TPI?

A: Yes, sure. Welcome visit our factory and come here to inspect the goods and inspect production process.

Q: Can you supply Form e, Certificate of origin?

A: Yes, we can supply.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you accept L/C deferred 30, 60, 90 days?

A: We can. Please negotiate with sales.

Q: Can you accept O/A payment?

A: We can. Please negotiate with sales.

Q: Can you supply samples?

A: Yes, some samples are free, please check with sales.

Q: Can you supply the products which comply with NACE?

A: Yes, we can.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.