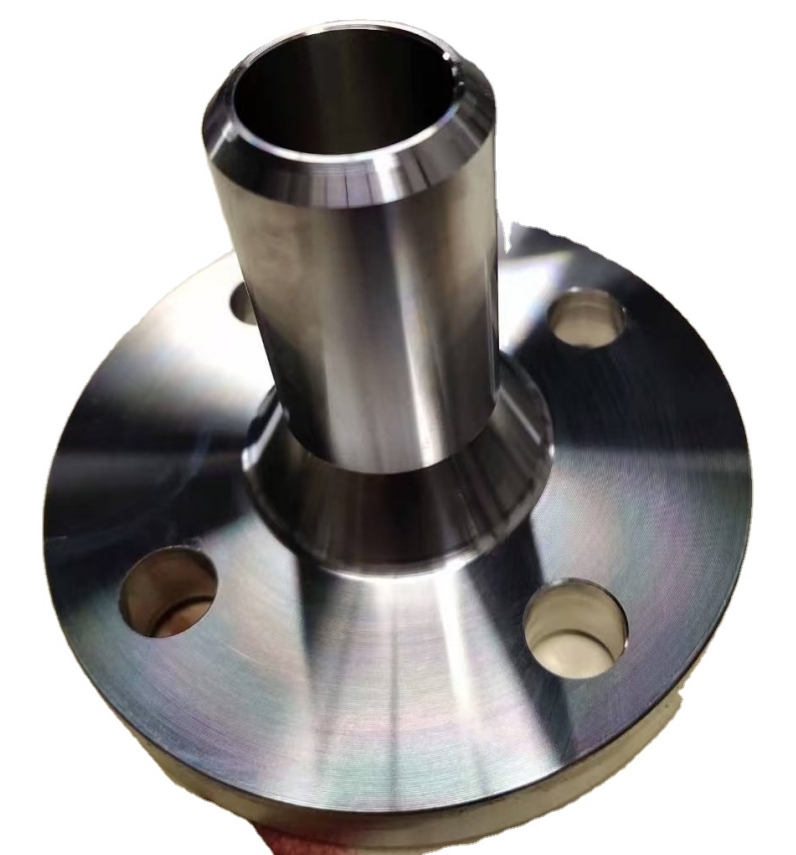

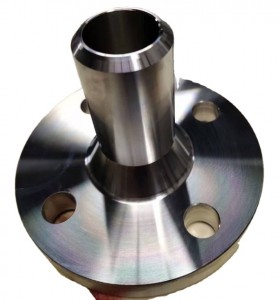

Customized Long Weld Neck (LWN) Flange

Our Customized Long Weld Neck (LWN) Flanges represent the ultimate solution for critical piping applications where standard flanges cannot meet unique project requirements. Engineered for extreme service conditions in offshore, petrochemical, power generation, and high-pressure processing industries, these flanges are tailored to specific operational demands through advanced engineering and precision manufacturing.

Unlike off-the-shelf components, each customized LWN flange undergoes thorough design analysis to ensure optimal performance under specific pressure, temperature, corrosion, and mechanical stress conditions. The extended neck design provides superior stress distribution, making these flanges particularly suitable for high-pressure vessels, heat exchangers, reactors, and critical pipeline connections where fatigue resistance and long-term reliability are paramount. Our customization capabilities transform standard flange specifications into purpose-engineered solutions that address the most challenging industrial applications.

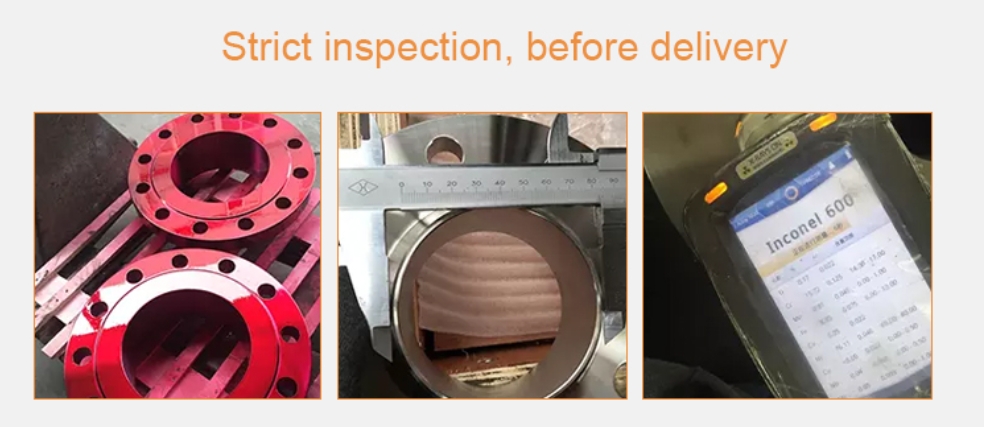

Quality Control for Custom Components:

Design Verification: Third-party design validation for critical applications

Prototype Testing: Fabrication of test pieces for material and process validation

Advanced NDT: Phased array UT, TOFD, and digital radiography for complex geometries

Dimensional Verification: Laser scanning and 3D measurement for custom profiles

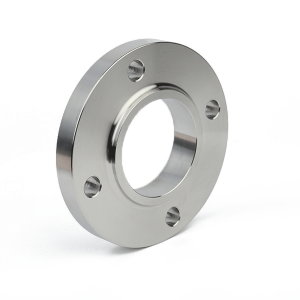

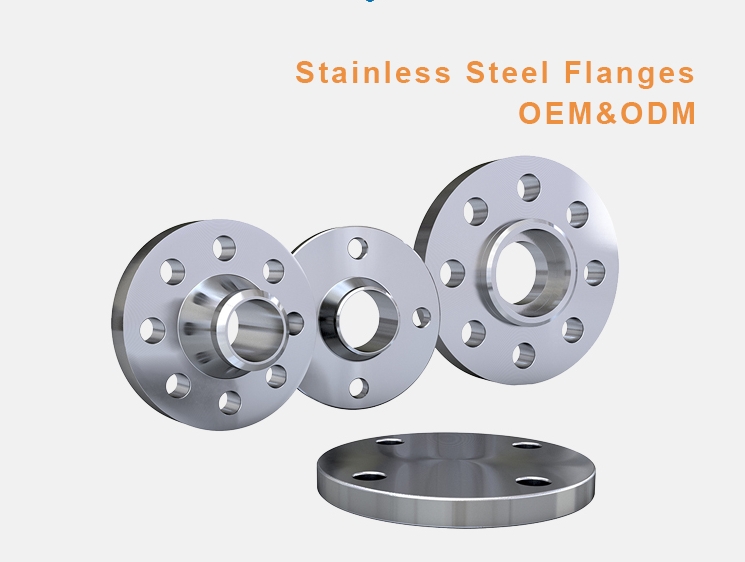

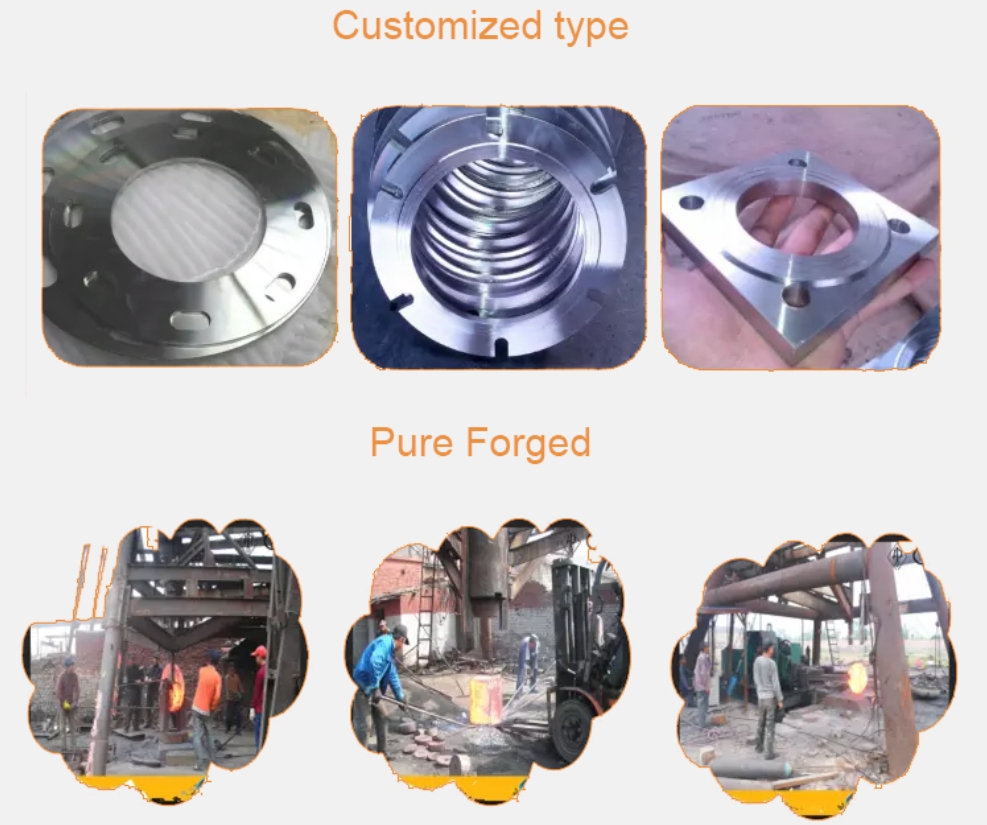

PRODUCTS DETAIL SHOW

Advanced Manufacturing Capabilities:

Forging: Closed-die forging for superior grain structure in high-pressure applications

Plate Fabrication: For oversized flanges where forging is impractical

Cladding/Overlay: Weld overlay of corrosion-resistant alloys on carbon steel base

Precision Machining: 5-axis CNC machining for complex geometries

Heat Treatment: Customized thermal cycles (normalizing, quenching, tempering) per material requirements

MARKING AND PACKING

Heavy-Duty Crating: Engineered wooden crates with custom internal bracing

Corrosion Protection: VCI coating, desiccant systems, and climate-controlled packaging

Surface Protection: Custom covers for machined surfaces and threaded holes

Handling Provisions: Integrated lifting lugs and center-of-gravity marking

INSPECTION

Design Validation Testing:

FEA Stress Analysis: ANSYS or equivalent software validation

Prototype Pressure Testing: Hydrostatic/pneumatic testing of sample components

Material Compatibility Testing: Corrosion testing in simulated service environments

Fatigue Analysis: Cyclic loading simulation for dynamic service conditions

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

Application

Offshore & Subsea: Manifold connections, Christmas tree flanges, riser connections

Power Generation: Nuclear primary system flanges, turbine bypass systems

Petrochemical: High-pressure reactor flanges, reformer furnace connections

Cryogenic Service: LNG liquefaction and regasification facilities

Mining & Minerals: High-pressure autoclave and digester systems

Our customized LWN flange service represents more than just manufacturing – it's a partnership approach to solving complex engineering challenges. We work closely with your engineering teams to develop solutions that not only meet specifications but optimize performance, reduce lifecycle costs, and ensure long-term reliability in the world's most demanding industrial applications.

Q: Can you accept TPI?

A: Yes, sure. Welcome visit our factory and come here to inspect the goods and inspect production process.

Q: Can you supply Form e, Certificate of origin?

A: Yes, we can supply.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you accept L/C deferred 30, 60, 90 days?

A: We can. Please negotiate with sales.

Q: Can you accept O/A payment?

A: We can. Please negotiate with sales.

Q: Can you supply samples?

A: Yes, some samples are free, please check with sales.

Q: Can you supply the products which comply with NACE?

A: Yes, we can.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.