Heavy Hex Galvanized Stud Bolts and Nuts

Our Heavy Hex Galvanized Stud Bolts and Nuts represent industrial-grade fastening solutions engineered for critical applications in oil & gas, petrochemical, power generation, and structural industries. Manufactured from high-strength carbon and alloy steel with precise thread geometry and protective galvanized coatings, these fasteners deliver exceptional clamping force, corrosion resistance, and long-term reliability in demanding environments.

The stud bolt configuration provides superior load distribution compared to conventional bolts, making them ideal for flange connections in high-pressure piping systems, pressure vessels, and heat exchangers. The heavy hex nut design offers increased wrenching surface for higher torque application and reduced rounding risk. Available with various galvanizing processes and specialty coatings, our fasteners are engineered to withstand corrosive atmospheres, temperature extremes, and cyclical loading conditions while maintaining their mechanical integrity and performance characteristics.

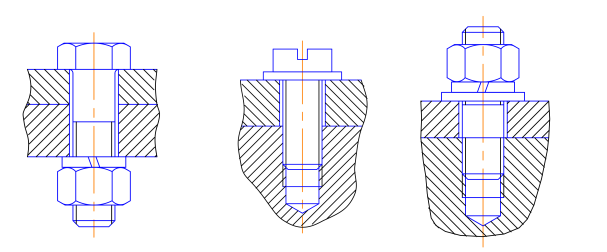

Different type bolt

The difference between bolts and screws lies in two aspects: one is the shape, the stud part of the bolt is strictly required to be cylindrical, used to install the nut, but the stud part of the screw is sometimes conical or even with a tip; the other is Using the function, the screw is screwed into the target material instead of the nut. In many occasions, the bolts also work individually, and are directly screwed into the pre-drilled threaded hole, without the need for a nut to cooperate with it. At this time, the bolt is classified as a screw in terms of function.

The shape and purpose of the bolt head are divided into hexagonal head bolts, square head bolts, half-round head bolts, countersunk head bolts, bolts with holes, T-head bolts, hook head (foundation) bolts and so on.

The thread of the column can be divided into coarse thread, fine thread and inch thread, so it is called fine bolt and inch bolt.

Material Specifications:

Stud Bolt Materials: ASTM A193 B7 (Chrome-Molybdenum Alloy), ASTM A320 L7 (Low Temperature), ASTM A307 (Carbon Steel)

Nut Materials: ASTM A194 2H (Heavy Hex), Grade 8, Grade 10

Chemical Composition: Controlled chemistry for specific mechanical properties

Heat Treatment: Quenched and tempered for optimal strength-toughness balance

Manufacturing Precision:

Thread Rolling: Cold forming process for superior thread strength and fatigue resistance

Heat Treatment: Controlled quenching and tempering cycles

Surface Preparation: Shot blasting for proper coating adhesion

Galvanizing Process: Hot-dip or mechanical galvanizing per ASTM A153/A153M

Thread Specifications:

Thread Type: UNC (Coarse), UNF (Fine), 8UN, Metric

Thread Class: 2A/2B for standard applications, 3A/3B for precision fits

Thread Length: Fully threaded or double-end studs with plain center section

Chamfer: Precision machined lead-in chamfers for easy assembly

Heavy Hex Nut Features:

Dimensions: ASME B18.2.2 compliance

Wrenching Surface: Increased flat-to-flat distance for higher torque capability

Thread Engagement: Full or partial thread options

Markings: Grade identification and manufacturer's mark

Galvanizing Process Options:

Hot-Dip Galvanizing: Zinc coating thickness 2-6 mils (50-150 microns)

Mechanical Galvanizing: Uniform zinc coating without hydrogen embrittlement risk

Post-Treatment: Passivation, quenching, or chromating for enhanced corrosion protection

Production Process

First, the first punch moves to prepare the wire for forming, and then the second punch moves to forge the wire again and shape the finished product. In the cold heading process, the fixed die (compression die) and the stamping (flattening) die (punching)

The number of heads) is not the same. Some complex screws may require multiple punches to form together, which requires multi-station equipment to make the screw forming.After the movement of the punch, the head of the screw has been completed, but the part of the screw shaft has not been threaded.The method of forming the screw thread is thread rolling. Thread rolling is the use of two relatively rotating thread rolling dies(rubbing plates) with threaded teeth to squeeze a cylindrical blank formed by amulti-station or heading machine in the middle.

After heading and rubbing the teeth, the entire screw has been produced. Of course, in order to make the appearance of the screw brighter and better, the surface treatment process is usually done. Such as cleaning and passivation of stainless steel screws,electroplating on the surface of carbon steel screws, etc. Made into various colors of screw fasteners.

Protective Packaging:

VCI Protection: Volatile Corrosion Inhibitor paper or bags

Individual Wrapping: For precision threads and coatings

Bundle Packaging: By size and grade with steel banding

Desiccant Inclusion: Humidity control for long-term storage

Identification & Marking:

Color Coding: Grade identification through painted ends or bands

Bag Tagging: Complete specifications on waterproof tags

Barcode System: For automated inventory management

Lot Numbering: For complete traceability

Shipping Configuration:

Wooden Crates: For large diameter and long length fasteners

Steel Drums: For bulk quantities with maximum protection

Pallets: Standardized pallet sizes for easy handling

Container Loading: Optimized for maximum weight and volume utilization

Documentation:

Packing Lists: Detailed by size, grade, and quantity

Material Certificates: Original or certified copies

Certificate of Origin: For international shipments

MSDS: Material Safety Data Sheets for coated products

Logistics Management:

Inventory Management: Real-time stock visibility

Just-in-Time Delivery: Synchronized with project schedules

Export Documentation: Complete customs clearance support

Tracking Systems: Online tracking for all shipments

Q: Can you accept TPI?

A: Yes, sure. Welcome visit our factory and come here to inspect the goods and inspect production process.

Q: Can you supply Form e, Certificate of origin?

A: Yes, we can supply.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you accept L/C deferred 30, 60, 90 days?

A: We can. Please negotiate with sales.

Q: Can you accept O/A payment?

A: We can. Please negotiate with sales.

Q: Can you supply samples?

A: Yes, some samples are free, please check with sales.

Q: Can you supply the products which comply with NACE?

A: Yes, we can.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.