Hastelloy Nickel inconel Incoloy Steel Pipe

We are specialized manufacturers and global suppliers of high-performance seamless pipes made from premium nickel alloys and special steels.

Our extensive product portfolio encompasses the complete range of Hastelloy alloys, Nickel series, Inconel grades, Incoloy variants, Monel specifications, and specialized stainless steels including C276, 400, 600, 601, 625, 718, 725, 750, 800, 825, and various alloy steel compositions.

These materials are specifically engineered to deliver exceptional performance in the most demanding industrial environments, offering superior resistance to extreme temperatures, high-pressure conditions, and corrosive media.

Product parameters

| Product name | seamless pipes, ERW pipe,EFW pipe, DSAW pipes. |

| Standard | ASME B36.10M, API 5L, ASTM A312, ASTM A213. ASTM A269, etc |

| Material | stainless steel: 304, 316, 317, 904L, 321, 304h, 316ti, 321H, 316H, 347, 254Mo, 310s, etc. |

| Super duplex steel:s31803,s32205, s32750,s32760, 1.4462, 1.4410, 1.4501, etc. | |

| Nickel alloy:inconel600, inconel 625, inconel 718, incoloy 800, incoloy 825, C276,

alloy 20, Monel 400, alloy 28 etc. |

|

| OD | 1mm-2000mm , customized. |

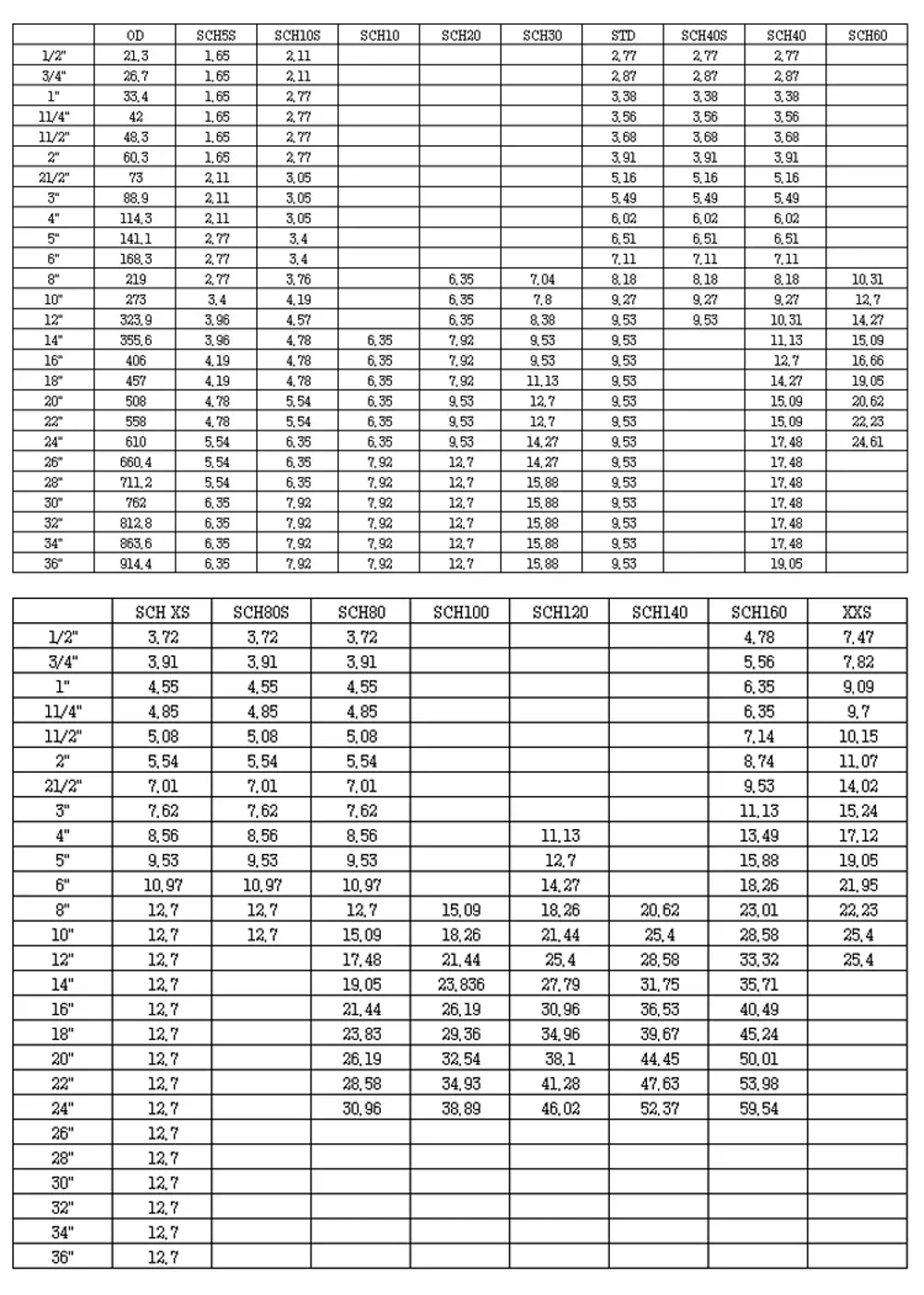

| Wall thickness | SCH5S SCH10S, SCH10, SCH20,SCH30, SCH40S, STD, SCH40, SCH80S, SCH80, XS, SCH60,

SCH100, SCH120,SCH140,SCH160,XXS, customized , etc |

| Length | 5.8m, 6m, 11.8m, 12m, SRL, DRL, or as required |

| Surface | Annealing, pickling, polishing, bright, sand blast,hair line, brush, satin, snow sand, titanium, etc |

| Application | Stainless steel pipe widely used in petroleum,chemical industry,electric power, boiler,high temperature resistant,

low temperature resistant, corrosion resistant., sour service, etc. |

| The size of the pipes can be made according to clients requirements. | |

| Contacts | If you have any questions, please feel free to contact me.we are sure your inquiry or requirements will get prompt attention. |

Each alloy in our collection possesses unique properties tailored for specific operational challenges. Hastelloy C276 demonstrates outstanding resistance to both oxidizing and reducing media, particularly in chloride-containing environments.

The Inconel series, including grades 600, 601, 625, 718, 725, and 750, offers excellent mechanical strength and oxidation resistance at elevated temperatures, with Inconel 718 maintaining remarkable yield strength up to 1300°F and Inconel 625 showing superior fatigue and thermal fatigue strength. Incoloy alloys 800 and 825 provide excellent resistance to oxidizing and reducing acids, with Incoloy 800HT specifically engineered for enhanced creep rupture properties.

Monel alloys 400 and K500 deliver exceptional corrosion resistance in marine and chemical processing applications, while the comprehensive stainless steel range ensures optimal performance across various corrosive environments.

specification

Stainless Seamless steel pipe

Packaging & Shipping

1. End will be protected by plastic caps.

2. Smaller tubes are packed by plywood case.

3. Bigger pipes are packed by bundling.

4. All package, we will put packing list.

5. Shipping marks on our request.

We ensure optimal product protection through individual plastic wrapping and durable plastic end caps. Bundled pipes are secured with steel straps and waterproof wrapping. Export shipments are protected in wooden crates with plastic lining for sea freight.

Inspection

1. PMI, UT test, PT test.

2. Dimension test.

3. Supply MTC, inspection certificate, EN10204 3.1/3.2.

4. NACE certificate, sour service

We implement comprehensive quality assurance protocols including full material traceability with mill test certificates. All pipes undergo non-destructive testing using ultrasonic and eddy current methods. Mechanical testing verifies tensile strength, yield strength, elongation, and hardness properties.

Before delivery, our QC team will arrange NDT test and dimension inspection.

Also accept TPI(third party inspection).

Application

Marine Applications

Our nickel alloy pipes demonstrate exceptional performance in seawater systems. Hastelloy C276 resists pitting in cooling systems, while Monel 400 handles seawater pipelines with superior durability. Super duplex steel serves reliably in deep-sea environments up to 3000 meters depth.

Chemical Processing

These pipes withstand aggressive chemical environments including sulfuric and phosphoric acids. Incoloy 825 is ideal for reaction vessels, and Hastelloy C276 handles chlorides and solvents effectively. All pipes pass strict intergranular corrosion testing for lasting performance.

Oil & Gas Sector

Inconel 718 meets NACE standards for sour service applications. Our alloy steel pipes perform reliably in refinery processing units under high temperatures and pressures. Subsea pipelines utilize duplex steel for combined strength and corrosion resistance.

Aerospace Industry

Inconel 718 and 725 alloys are specified for jet engine systems and hydraulic lines. These precision-made pipes maintain integrity in extreme temperature conditions and meet all aviation safety standards with full traceability.

FAQ

1. What is 304 round stainless steel pipe seamless white steel pipe?

304 round stainless steel pipe seamless white steel pipe is a cylindrical pipe made of 304 grade stainless steel, seamless and with a white surface.

2. What is the difference between seamless steel pipe and welded steel pipe?

Seamless steel pipes are manufactured without any welds and have a smoother and more uniform surface. Welded steel pipe is made by welding two or more sections of steel together.

3. What are the benefits of using grade 304 stainless steel?

Grade 304 stainless steel is highly corrosion-resistant, making it suitable for a variety of applications. It also offers excellent strength and durability, good heat resistance, and is easy to clean and maintain.

4. What are the common uses of 304 round stainless steel pipe and seamless white steel pipe?

These pipes are commonly used in industries such as food processing, pharmaceutical, chemical, petrochemical, and construction. They can be used to transport fluids, gases and solids as well as in structural applications.

5. Can 304 round stainless steel pipe seamless white steel pipe be used for outdoor applications?

Yes, grade 304 stainless steel is suitable for outdoor applications as it resists corrosion caused by exposure to moisture, chemicals, and harsh weather conditions.

6. What is the maximum temperature that 304 round stainless steel pipe seamless white steel pipe can withstand?

Grade 304 stainless steel has a maximum operating temperature of approximately 870°C (1600°F), making it suitable for high temperature applications.

7. How to ensure the quality of 304 round stainless steel seamless white steel pipe?

The quality of these pipes is ensured through various tests and inspections, including chemical composition analysis, mechanical testing, dimensional inspection, and non-destructive testing methods such as ultrasonic testing.

8. Can the size and length of 304 round stainless steel seamless white steel pipe be customized?

Yes, these tubes can be customized to specific requirements in terms of size, length and even surface finish. Customization options are available to meet the diverse needs of different applications.

9. How should 304 round stainless steel seamless white steel pipes be stored?

To ensure proper storage, these tubes should be kept in a dry and clean environment, preferably indoors. They should be protected from moisture, chemicals and physical damage during storage.

10. Are there any certifications for 304 round stainless steel seamless white steel pipes?

Yes, reputable manufacturers can provide certifications such as Material Test Reports (MTR), Factory Test Certificates (MTC) and Certificates of Compliance to ensure product quality and traceability.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

Pipe Stainless Steel Aisi 304l Seamless Thickne...

-

Best Cheap Stainless Steel Coupling Pricelist &...

-

C276 400 600 601 625 718 725 750 800 825SS Seri...

-

Inconel 718 601 625 Monel K500 32750 Incoloy 82...

-

A249 stainless steel seamless pipe thickness 1....

-

ASME SA213 T11 T12 T22 Seamless Tube Pipe Stain...