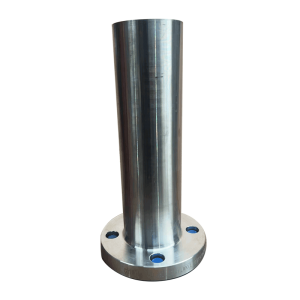

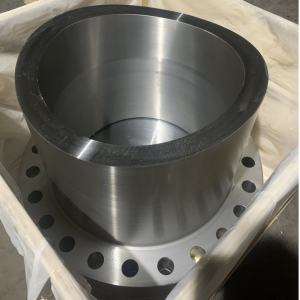

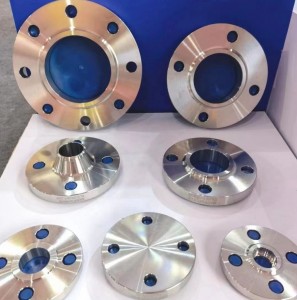

Long Weld Neck Flange - Forged Steel LWN Flanges 304/316L

Our Long Weld Neck Flanges (LWN) represent the pinnacle of forged flange technology, designed specifically for critical applications requiring superior performance under extreme conditions. Manufactured from premium stainless steel grades 304 and 316L, these flanges provide exceptional corrosion resistance and mechanical strength. The extended neck design ensures optimal stress distribution, making them ideal for high-pressure systems, process piping, and severe service applications where reliability is paramount.

Design Features & Benefits

Extended Neck Length: Provides superior stress distribution and reduces pipe stress concentration

Precision Forging: Ensures uniform grain structure and enhanced mechanical properties

Smooth Bore: Minimizes turbulence and pressure drop in fluid systems

Optimized Hub Taper: Gradual transition for improved fatigue resistance

Accurate Thickness: Maintains consistent wall thickness throughout the flange body

Manufacturing Excellence

Material Selection: Premium-grade stainless steel billets with full traceability

Forging Process: Closed-die forging for superior metallurgical properties

Heat Treatment: Solution annealing and quenching for optimal corrosion resistance

Machining: CNC precision machining with strict tolerance control

Quality Verification: 100% dimensional inspection and material certification

MARKING AND PACKING

Export Packaging: Wooden crates with proper bracing and waterproof lining

Surface Protection: Anti-corrosion coating and plastic end caps

Clear Marking: Permanent identification with heat numbers and specifications

Documentation: Complete mill test certificates and shipping documents

Global Logistics: Efficient shipping arrangements worldwide

INSPECTION

Material Certification: Full compliance with ASTM A182 specifications

Chemical Analysis: Spectrometer verification of composition

Mechanical Testing: Tensile, yield strength, elongation, and hardness tests

Non-Destructive Testing: Liquid penetrant, ultrasonic, or magnetic particle inspection

Surface Inspection: Visual examination for defects and surface quality

Dimensional Verification: Comprehensive measurement per ASME standards

Our Capabilities & Advantages

Custom Manufacturing: Tailored solutions for specific project requirements

Quick Delivery: Large inventory and flexible production scheduling

Technical Support: Engineering expertise for application guidance

Quality Certifications: ISO 9001:2015, PED 2014/68/EU, NACE MR0175

Global Standards: Compliance with international specifications and codes

Competitive Pricing: Cost-effective solutions without compromising quality

Why Choose Our LWN Flanges?

Proven Reliability: Extensive track record in critical applications

Technical Expertise: Deep understanding of flange design and application

Quality Commitment: Stringent quality control at every production stage

Customer Support: Responsive service and technical assistance

Industry Experience: Years of serving global clients across multiple sectors

Application

Petrochemical Processing

Long Weld Neck flanges provide secure connections in refinery reactors and high-pressure vessels, with extended necks reducing stress concentrations in cyclic service conditions. The 316L material offers excellent resistance to sulfide corrosion.

Power Generation Systems

LWN flanges serve critical roles in boiler feed systems and steam headers, where their reinforced structure maintains seal integrity under thermal cycling. The extended neck design minimizes thermal stress in high-temperature applications.

Offshore Marine Applications

These flanges withstand corrosive seawater environments in platform piping and subsea systems. 316L grade provides superior pitting resistance, while the long neck accommodates pipeline movement and vibration.

High-Pressure Pipeline Networks

In oil and gas transmission systems, LWN flanges ensure leak-proof connections at pumping stations and compressor outlets. The forged construction handles pressure surges and mechanical stresses effectively.

Our Long Weld Neck Flanges are engineered to deliver unmatched performance in the most demanding environments. With rigorous quality control and extensive manufacturing expertise, we ensure every flange meets the highest standards of reliability and durability. Contact us today to discuss your specific requirements and discover how our LWN flanges can enhance your piping system's performance and safety.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.