Manufacturer for Weldolet - Black Steel Hot Induction Bend – C. Z. IT Detail:

Product parameters

| Product Name | Hot induction bend |

| Size | 1/2″-36″ seamless, 26″-110″ welded |

| Standard | ANSI B16.49, ASME B16.9 and customized etc |

| Wall thickness | STD, XS, SCH20,SCH30,SCH40, SCH60, SCH80,SCH100 ,SCH120,SCH140, SCH160, XXS ,customized, etc. |

| Elbow | 30° 45° 60° 90° 180°,etc |

| Radius | multiplex radius, 3D and 5D is more popular, also can be 4D, 6D, 7D, 10D,20D, customized, etc. |

| End | Bevel end/BE/buttweld, with or with tangent(straight pipe on each end) |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel:API 5L Gr.B, A106 Gr. B, A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: API 5L X42, X52,X46,X56, X6-, X65, X70, X80, ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 15XM, 10CrMo9-10, 16Mo3 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

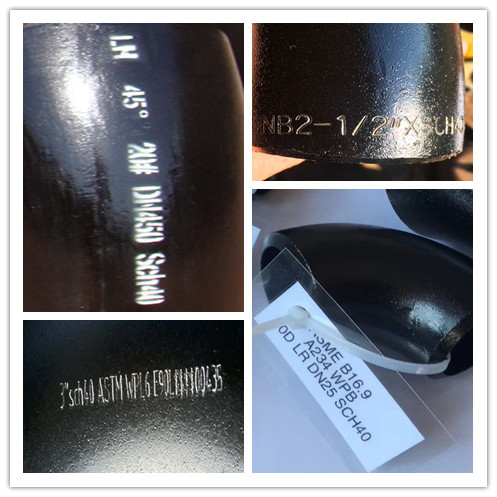

Marking

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO

Detailed photos

1. Bevel end as per ANSI B16.25.

2. Sand blast first, then Perfect painting work. Also can be varnished.

3. Without lamination and cracks.

4. Without any weld repairs.

5. Can be with or without straightpipe on each end.

6. Painting color can be others, like blue, red, gray, etc.

7. We can offer 3LPE coating or other coating on your request.

Inspection

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request.

3. PMI.

4. MT, UT,PT, X-ray test.

5. Accept Third party inspection.

6. Supply MTC, EN10204 3.1/3.2 certificate.

Packaging & Shipping

1. Packed by plywood case or plywood pallet as per ISPM15

2. we will put packing list on each package

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free

5. To save shipping cost, customers always need no package. Put the bend into container directly

Product detail pictures:

Related Product Guide:

What are duplex stainless steel applications?

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for Manufacturer for Weldolet - Black Steel Hot Induction Bend – C. Z. IT, The product will supply to all over the world, such as: Slovakia, Norway, Israel, After 13 years of researching and developing products, our brand can represent wide range of products with outstanding quality in world market. We have completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

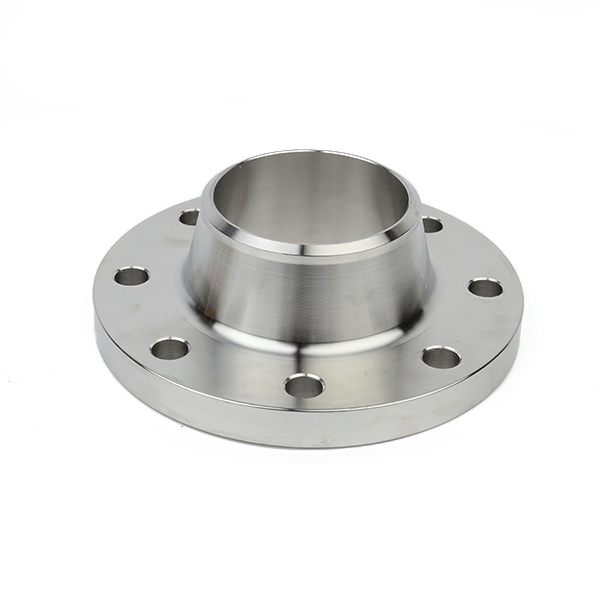

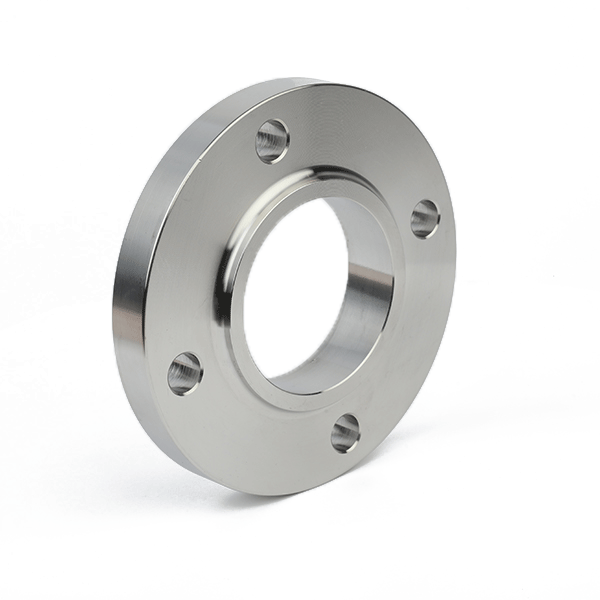

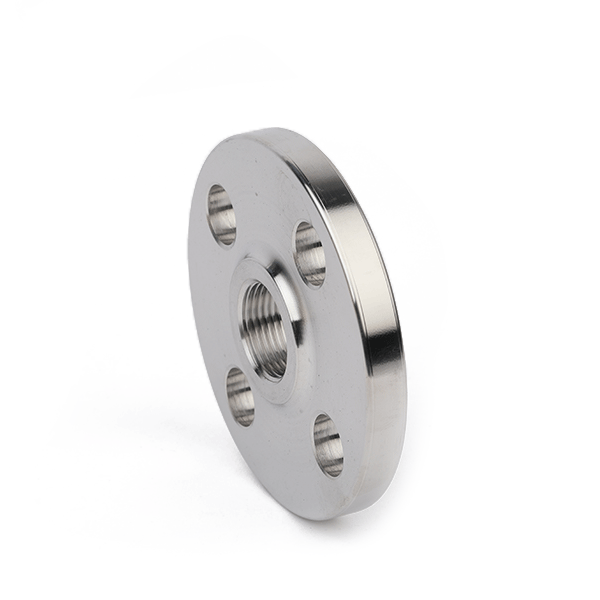

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.