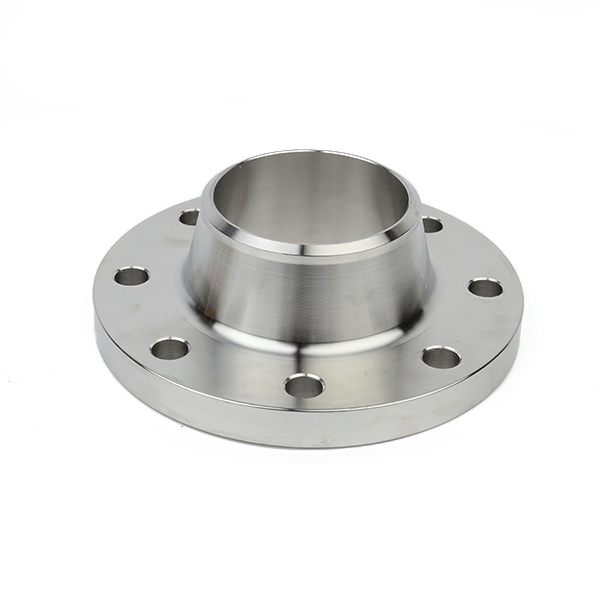

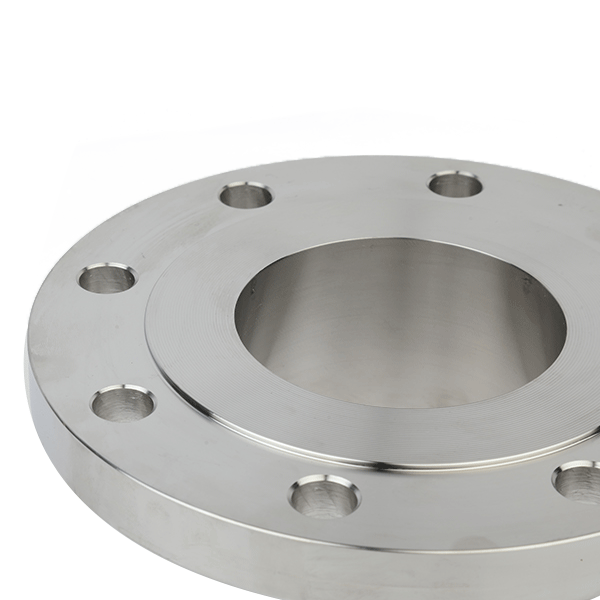

New Fashion Design for Forged Welded Neck Flange - Forged Weld Neck Flange – C. Z. IT Detail:

Specification

| Product Name | weld neck flange |

| Size | 1/2″-110″ |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

Production process

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| S.O.R.F |

12 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

48 |

| S.O.R.F |

8 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

2 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

4 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

16 |

TANK FLANGES |

8 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

24 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

16 |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

10 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

PSB1 |

2 |

| Flange, Weld Neck |

6 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

4 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

18 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

Product detail pictures:

Related Product Guide:

What are duplex stainless steel applications?

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for New Fashion Design for Forged Welded Neck Flange - Forged Weld Neck Flange – C. Z. IT, The product will supply to all over the world, such as: Florence, Kuwait, Montreal, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.