Main types of flange gaskets

Non-metallic gaskets

Typical materials: rubber, polytetrafluoroethylene (PTFE), non-asbestos fiber (rubber asbestos).

Main uses and features:

Widely used in water, air, steam, acid and alkali media, rubber asbestos gaskets were once a common choice.

Widely used in water, air, steam, acid and alkali media, rubber asbestos gaskets were once a common choice.

For corrosion-resistant scenarios, PTFE gaskets have excellent chemical stability.

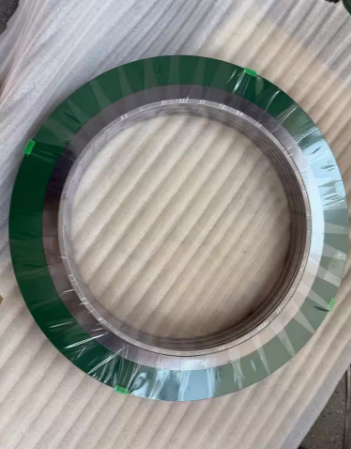

Semi-metallic gaskets

Typical materials: Metal band + graphite/asbestos/PTFE-filled band (wound type), metal-clad non-metallic core, flexible graphite composite gasket.

Main uses and features:

Combining the strength of metal and the elasticity of non-metal in high-temperature, high-pressure and variable working conditions. Among them, metal wound gaskets are the mainstream choice in the petrochemical, chemical and other industries.

For strong sealing requirements, such as metal serrated/wavy ring gaskets, they are used in pipelines or pressure vessels with higher pressure and temperature.

Metal gaskets

Typical materials: mild steel, stainless steel, copper, Monel alloy.

Main applications and features:

Extreme conditions: used in high-temperature, high-pressure and highly corrosive media.

They offer excellent sealing performance but have extremely high requirements for the processing accuracy of the flange sealing surface and installation, and are expensive.

When choosing gaskets, multiple factors need to be comprehensively considered. The core lies in four key points: “medium, pressure, temperature, and flange“.

Medium properties: For corrosive media (such as acids and alkalis), the gasket material must be corrosion-resistant.

Working pressure and temperature: In high-temperature and high-pressure conditions, metal or semi-metallic gaskets that can withstand temperature and pressure must be selected.

Flange sealing surface type: Different flange surfaces (such as raised face RF, male and female face MFM, tongue and groove face TG) must be matched with specific gasket types.

Other factors: Vibration, frequent fluctuations in temperature and pressure, the need for frequent disassembly, and cost budget must also be considered.

Overall,

For low pressure and common media (water, air, low-pressure steam): Non-metallic gaskets, such as rubber or PTFE gaskets, are preferred due to their high cost-effectiveness.

For medium to high pressure, high temperature or complex working conditions (pipelines in the petroleum, chemical and power industries): Semi-metallic gaskets, especially metal-wound gaskets, are the most common and reliable choice.

For extremely high temperature and pressure or strong corrosive conditions: Metallic gaskets (such as corrugated or ring gaskets) should be considered, but it is essential to ensure proper flange matching and correct installation.

https://www.czitgroup.com/stainless-steel-graphite-packing-spiral-wound-gasket-product/?fl_builder

Post time: Jan-15-2026