OEM Welded Pipe Factory – Black Steel Hot Induction Bend – C. Z. IT Detail:

PRODUCT PARAMETERS

| Product Name | Hot induction bend |

| Size | 1/2″-36″ seamless, 26″-110″ welded |

| Standard | ANSI B16.49, ASME B16.9 and customized etc |

| Wall thickness | STD, XS, SCH20,SCH30,SCH40, SCH60, SCH80,SCH100 ,SCH120,SCH140, SCH160, XXS ,customized, etc. |

| Elbow | 30° 45° 60° 90° 180°,etc |

| Radius | multiplex radius, 3D and 5D is more popular, also can be 4D, 6D, 7D, 10D,20D, customized, etc. |

| End | Bevel end/BE/buttweld, with or with tangent(straight pipe on each end) |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel:API 5L Gr.B, A106 Gr. B, A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: API 5L X42, X52,X46,X56, X6-, X65, X70, X80, ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 15XM, 10CrMo9-10, 16Mo3 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

BENEFITS OF HOT INDUCTION BENDING

Better Mechanical Properties:

The hot induction bend method ensures the mechanical properties of the main pipe comparing with cold bend and welded solutions.

Reduces Weld and NDT Costs:

Hot bend is a good way to reduce the number of welds and non-destructive costs and risks on the material.

Rapid Manufacturing:

Induction bending is a highly effective way of pipe bending, as it is fast, precise, and with few errors.

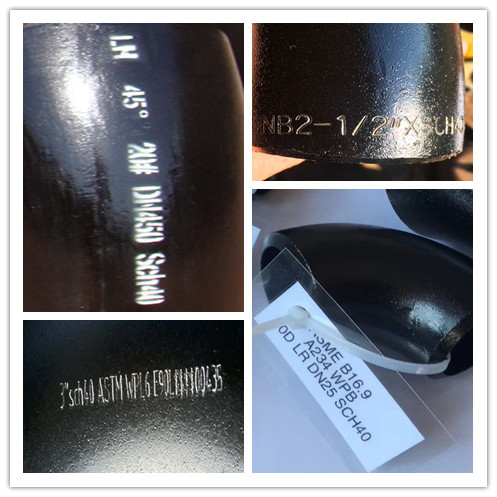

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Sand blast first, then Perfect painting work. Also can be varnished.

3. Without lamination and cracks.

4. Without any weld repairs.

5. Can be with or without straightpipe on each end.

6. Painting color can be others, like blue, red, gray, etc.

7. We can offer 3LPE coating or other coating on your request.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request.

3. PMI.

4. MT, UT,PT, X-ray test.

5. Accept Third party inspection.

6. Supply MTC, EN10204 3.1/3.2 certificate.

PACKAGING & SHIPPING

1. Packed by plywood case or plywood pallet as per ISPM15

2. we will put packing list on each package

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free

5. To save shipping cost, customers always need no package. Put the bend into container directly

Product detail pictures:

Related Product Guide:

What are duplex stainless steel applications?

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for OEM Welded Pipe Factory – Black Steel Hot Induction Bend – C. Z. IT, The product will supply to all over the world, such as: Finland, Mozambique, Adelaide, So far our products have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have 13years professional sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality products and excellent service.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.