Orifice flange WN 4″ 900# RF A105

The 4" 900# Weld Neck Orifice Flange in ASTM A105 represents a precision-engineered flow measurement component designed for critical high-pressure service in the oil & gas, petrochemical, and power generation industries. Manufactured in strict compliance with ASME B16.36 (Orifice Flanges) and B16.5 standards, this flange incorporates dual Grade 3 drain (vent) holes as standard, facilitating accurate pressure tapping and ensuring reliable differential pressure measurement for custody transfer and process control.

SPECIFICATION

|

Product Name

|

weld neck Orifice flange

|

|||

|

SIZE

|

1" up ro 24"

|

|||

|

Pressure

|

150#-2500#

|

|||

|

Standard

|

ANSI B16.36

|

|||

|

Wall thickness

|

SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc.

|

|||

|

Material

|

Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S,

A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. Carbon steel: A105, A350LF2, Q235, St37, St45.8, A42CP, E24 , A515 Gr60, A515 Gr 70 |

|||

|

Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 ,

UNS32760, 1.4462,1.4410,1.4501 and etc. Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. |

||||

|

Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,

C22, C-276, Monel400, Alloy20 etc. Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 etc. |

||||

|

Application

|

Petrochemical industry;avation and aerospace industry;pharmaceutical industry;

gas exhaust;power plant;ship building;water treatment,etc. |

|||

|

Advantages

|

ready stock,faster delivery time;available in all sizes,customized;high quality

|

|||

Forged from ASTM A105 carbon steel—dual certified for enhanced traceability—this weld neck flange provides superior mechanical strength and impact resistance. The 900# pressure rating ensures integrity in systems operating up to 1500 psi at 100°F (with appropriate temperature derating). Its design prioritizes a smooth transition from pipe to flange via the integral neck, minimizing turbulence and optimizing flow conditions upstream and downstream of the orifice plate.

DIMENSION STANDARDS

PRODUCTS DETAIL SHOW

Forged Construction:

Each flange begins as a heated carbon steel billet, forged under high pressure to refine the grain structure, enhance mechanical properties (particularly toughness and fatigue resistance), and eliminate internal voids or defects. This process ensures uniformity and strength superior to cast or plate-cut alternatives.

Precision Machining:

CNC machining guarantees exacting tolerances on all critical surfaces. The bore is machined to a smooth finish to minimize flow disturbance. The raised face is precisely serrated (125-250 AARH finish) to maximize gasket grip and sealing effectiveness. Bolt holes are drilled and spot-faced to ensure perfect alignment and even bolt loading.

Orifice-Specific Features:

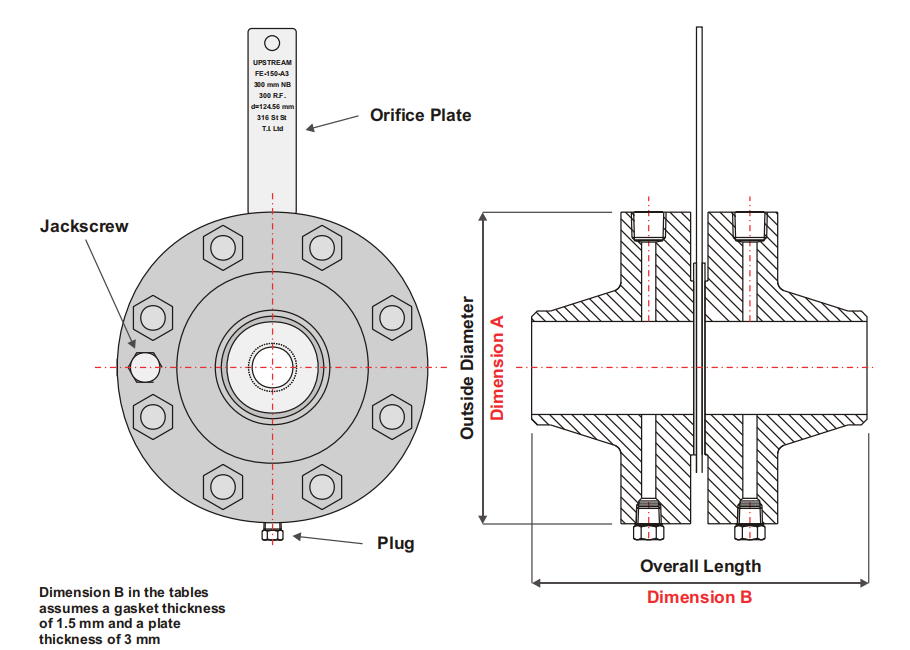

The flange includes two 1/2" NPT (or equivalent) Grade 3 drain/vent tap holes positioned 90 degrees apart, complying with standard orifice flange configurations for pressure transmitter connections. The mating surface is designed to house a standard orifice plate with a concentric, sharp-edged bore for accurate flow measurement.

Weld Preparation:

The weld neck end is beveled at a standard 37.5° angle with a 1.6mm land, prepared for a full-penetration butt weld to the matching Schedule 160 pipe. This design ensures the weld is removed from the high-stress flange face, providing the highest joint integrity.

Material Certification:

Supplied with full ASTM A105 dual certification (chemical and mechanical properties from both heat and product analysis), ensuring the material meets or exceeds minimum yield strength (250 MPa) and tensile strength (485 MPa) requirements.

MARKING AND PACKING

Each orifice flange is individually prepared for shipment. After a final anti-corrosion oil or VCI (Vapor Corrosion Inhibitor) coating, the flange is wrapped in heavy-duty plastic or waterproof paper. Critical machined surfaces—especially the raised face and bore—are protected with custom-cut plastic or cardboard caps. Flanges are then securely strapped to a wooden pallet or packed in a reinforced wooden crate, depending on order quantity and destination.

INSPECTION

Material Certification: Each flange is supplied with a full Mill Test Certificate (MTC) conforming to EN 10204 3.1 / ASTM A961. This certificate provides traceability to the original heat of steel and includes:

Full chemical analysis (C, Mn, P, S, Si, Cu, etc.)

- Results of mechanical tests (Tensile Strength, Yield Strength, Elongation, Reduction of Area)

- Charpy Impact test results (if specified for low-temperature service)

- Heat treatment records (normalizing, if applied)

COOPERATION CASE

Engineered for precise metering applications, this flange guarantees dimensional stability under thermal and pressure cycling. The Raised Face (RF) finish ensures a reliable seal with spiral-wound or ring joint gaskets, while the Schedule 160 heavy-wall construction provides an added safety margin for erosive or high-pressure drop services. As a cornerstone of safe and accurate fluid measurement, this orifice flange is a critical component for engineers demanding accuracy, durability, and full compliance with international pressure equipment codes.

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

Wide Application Scenarios: This 4" 900# orifice flange is engineered for demanding applications across several critical industries:

- Oil & Gas: Custody transfer metering stations, wellhead production manifolds, compressor station suction/discharge lines, and refinery process lines for crude, gas, or refined products.

- Petrochemical & Chemical: Precise feed control to reactors, flow measurement of aggressive or high-value process streams, and utility steam & condensate systems.

- Power Generation: Main steam, feedwater, and fuel gas lines in thermal power plants, where accurate mass flow measurement is essential for efficiency and safety.

- High-Pressure Utilities: Any industrial plant requiring reliable, high-integrity flow measurement for process control, accounting, or safety interlocking.

Our Company's Supply Advantages:

- In-House Forging & Machining: We maintain complete control over the production process—from raw material to finished flange—ensuring quality, traceability, and schedule adherence.

- Technical Expertise: Our engineering team can provide support on orifice sizing, gasket selection, installation torque specs, and compliance with project-specific standards (e.g., Shell DEPs, Aramco standards).

- Flexibility & Customization: While we supply standard B16.36 flanges, we can also accommodate special requirements, such as different tap hole configurations (corner taps, radius taps), special coatings, or heat treatment for low-temperature applications.

- Competitive Logistics: As a direct manufacturer with extensive export experience, we offer reliable lead times and optimize packaging and shipping to deliver cost-effectively to job sites worldwide.

- Quality Assurance: Our commitment extends beyond delivery. We provide complete documentation and support to ensure our flanges integrate seamlessly into your piping systems, providing years of reliable, accurate service.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

WN ANSI B16.36 orifice weld neck flange with ja...

-

Standard Pressure Orifice Flange Forged Stainle...

-

ASME B16.5 BL RF ASTM A182 F316L Stainless stee...

-

Customized Flange ANSI/ASME/JIS Standard Carbon...

-

ASME B16.48 CL150 CL300 Paddle spacer plank fla...

-

paddle blank spacer A515 gr 60 figure 8 spectac...