paddle blank spacer A515 gr 60 figure 8 spectacle blind flange

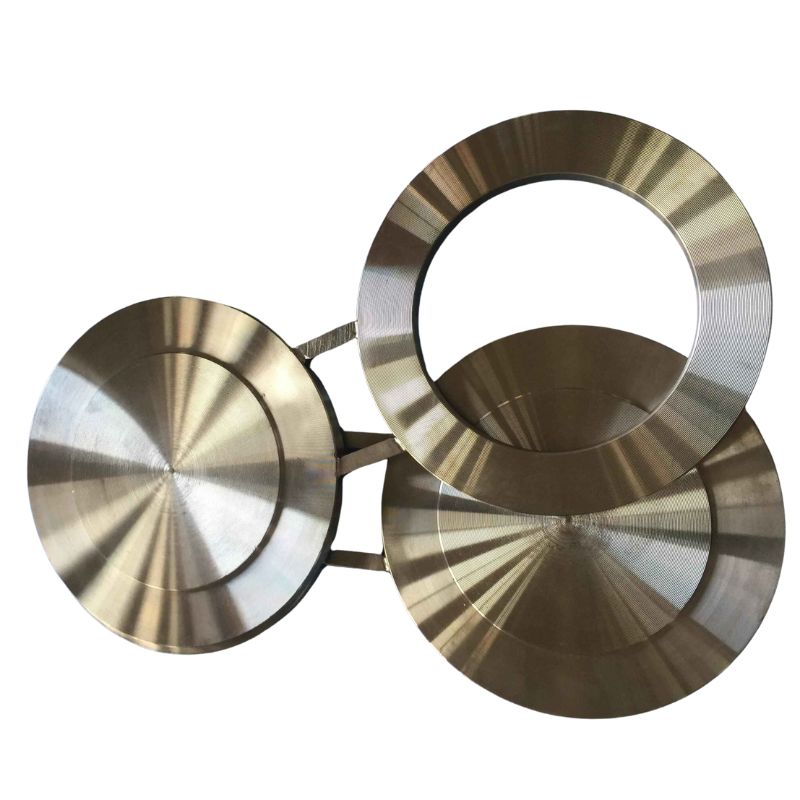

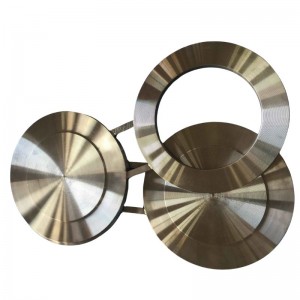

The Paddle Blank Spacer in ASTM A515 Grade 60, configured as a Figure-8 Spectacle Blind Flange, is a critical safety and isolation device in industrial piping systems. It ingeniously combines three functions into one robust unit: a solid blind plate for positive isolation, a spacer ring for flow-through, and a connecting web with an extended “paddle” handle for clear visual identification.

Forged or fabricated from pressure vessel quality ASTM A515 Grade 60 carbon steel, this component offers excellent strength and durability for moderate to high-temperature service. The “figure-8” design allows operators to quickly determine the line’s status (open or isolated) from a distance, a vital feature for lockout/tagout (LOTO) procedures and plant safety. Manufactured to ASME B16.48 standards, it ensures reliable performance as a line blank, providing an absolute, leak-tight seal when the solid end is bolted between flanges. Its robust construction makes it an indispensable tool for safe maintenance, system testing, and process configuration changes in demanding environments.

SPECIFICATION

| Product Name | Blind flange |

| Size | 1/2"-250" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

DIMENSION STANDARDS

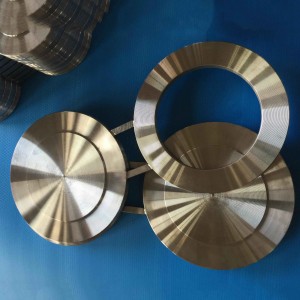

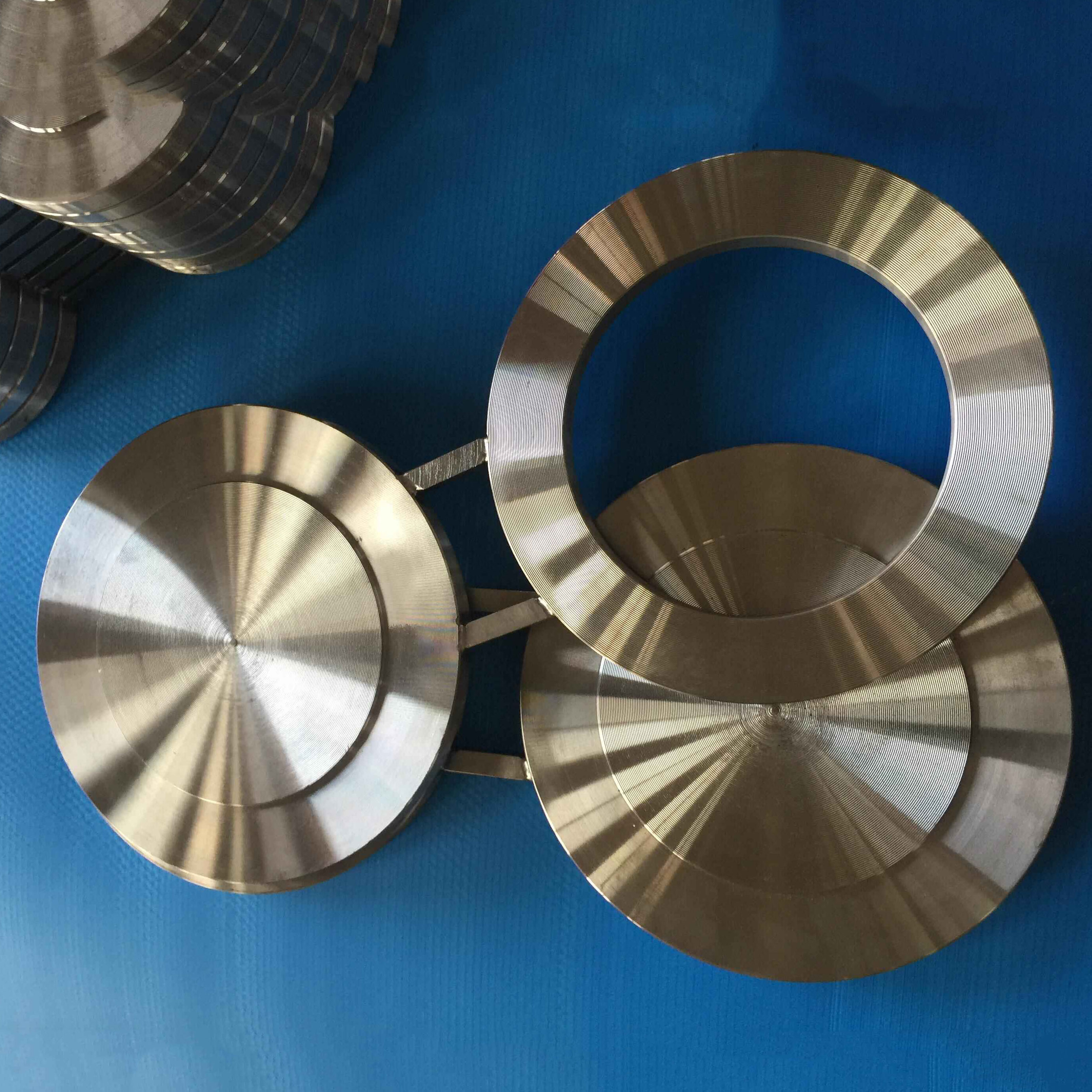

PRODUCTS DETAIL SHOW

Material & Construction:

The spectacle blind is precision-cut from ASTM A515 Grade 60 plate steel, a material specified for moderate and higher temperature pressure vessel applications. It offers a minimum tensile strength of 415 MPa (60 ksi) and good weldability. For critical service, A516 Grade 60 or 70 can be supplied.

Precision Machining:

All surfaces, especially the sealing faces that contact the gasket, are machined to a smooth finish (typically 125-250 AARH serrated finish for RF). The bolt holes are drilled and reamed to exact ASME B16.5 specifications, ensuring perfect alignment with mating flanges and preventing bolt stress during installation.

Design Features:

The central “paddle” is an integral part of the spectacle, providing a sturdy handle for rotation and a clear visual indicator. It is often painted in high-visibility colors (e.g., yellow for the spacer side, red for the blind side) per plant standards. The thickness of both the blind and spacer sections is calculated to withstand full pipeline pressure and provide proper gasket compression without bending.

Functionality:

The unit rotates on the bolts between the two pipe flanges. In the “open” position, the spacer ring aligns with the pipe bore, allowing flow. In the “closed” or “blinded” position, the solid plate completely blocks the line, providing a positive isolation point superior to a closed valve.

Marking:

Permanently stamped per ASME B16.48 requirements, including material grade (A515 Gr.60), size, pressure class, and manufacturer’s identification.

MARKING AND PACKING

Packaging: Each spectacle blind is individually protected. Machined sealing faces are coated with a rust preventative and covered with plastic or cardboard caps. The unit is then wrapped in VCI (Vapor Corrosion Inhibitor) paper or plastic to prevent corrosion during transit. For larger sizes, custom wooden crates with internal bracing are used. Smaller sizes may be bundled on a pallet with edge protection.

Marking: A weather-resistant tag is attached, detailing the part number, size, pressure class, material, and destination. The crate or bundle is clearly labeled with handling symbols (e.g., “This Side Up,” “Keep Dry”).

Shipping: We utilize optimal shipping methods based on order size and urgency—from standard sea containers for large orders to air freight for urgent project needs. All necessary shipping documents (packing list, commercial invoice, certificate of origin) are prepared meticulously to ensure smooth customs clearance worldwide.

INSPECTION

Every ASTM A515 Grade 60 steel plate undergoes comprehensive material certification. We conduct spectrochemical analysis to verify chemical composition meets grade requirements, including carbon, manganese, phosphorus, sulfur, and silicon content. Mechanical property testing includes tensile strength (minimum 415 MPa), yield strength (minimum 205 MPa), and elongation measurements per ASTM A370 standards. For low-temperature applications, optional Charpy V-Notch impact testing at specified temperatures (-29°C minimum standard) can be performed to validate material toughness.

Each spectacle blind flange undergoes 100% dimensional verification using calibrated measuring instruments. Critical dimensions inspected include: outer diameter (±1.5mm tolerance), bolt circle diameter (±0.8mm), bolt hole diameter and position (±0.5mm), thickness (±0.5mm per ASME B16.48 requirements), and face-to-face flatness (within 0.2mm across sealing surfaces). Special attention is given to the paddle handle alignment and clearance verification for proper rotation between standard ASME B16.5 flanges.

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

Product introduction

Versatile Application Scenarios: This Figure-8 Spectacle Blind is a universal safety device used across industries wherever piping systems require reliable isolation:

- Refineries & Petrochemical Plants: For isolating reactors, columns, heat exchangers, and pumps during maintenance or catalyst changeover.

- Oil & Gas Production/Transmission: On pipeline manifolds, wellheads, and before pressure safety valves (PSVs) for safe isolation during testing or repair.

- Power Generation: In steam lines, feedwater systems, and fuel lines to isolate sections of the plant for overhaul.

- Chemical & Pharmaceutical Processing: To prevent cross-contamination between batches or during equipment cleaning (CIP/SIP).

- Water Treatment & Shipbuilding: For isolating pumps, valves, and tanks in utility systems.

Our Supply & Manufacturing Advantages:

- Complete In-House Fabrication: We control the entire process from material procurement, cutting, machining, to finishing, ensuring quality and on-time delivery.

- Material Expertise: We provide guidance on material selection (A515 vs. A516, carbon steel vs. stainless steel) based on your specific service conditions (temperature, pressure, corrosivity).

- Customization Capability: We can manufacture spectacle blinds to non-standard thicknesses, with special hole patterns, unique handle designs, or in alternative materials (stainless steel, alloy steel) upon request.

- Safety-First Design: Our products are manufactured with operator safety in mind, featuring clear, robust paddles and precise dimensions for easy and safe handling during installation and rotation.

- Global Supply Chain Efficiency: As an experienced exporter, we package and document shipments to meet international standards, ensuring your safety-critical components arrive on-site ready for installation. We provide full technical data and support to facilitate smooth integration into your maintenance and safety procedures

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.