SS 304 & 316 Stainless Steel Sanitary Pipe Fitting

Our SS 304 & 316 Stainless Steel Sanitary Pipe Fittings are engineered to meet the most stringent hygienic requirements of the food & beverage, pharmaceutical, biotechnology, and cosmetic industries. As essential components in hygienic process piping systems, these precision-manufactured elbows, tees, and complementary fittings ensure product purity, prevent contamination, and facilitate efficient cleaning procedures.

Manufactured from certified AISI 304 or superior corrosion-resistant 316/316L stainless steel, these fittings feature crevice-free designs with polished internal surfaces that exceed industry standards for cleanability. Available with multiple connection options including Tri-Clamp and orbital butt weld, they provide versatile solutions for both permanent installations and systems requiring frequent disassembly for maintenance or batch changeovers. Each fitting is designed with zero dead legs to prevent bacterial harborage and is fully compatible with Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures, ensuring compliance with global sanitary regulations and GMP requirements.

Data sheet

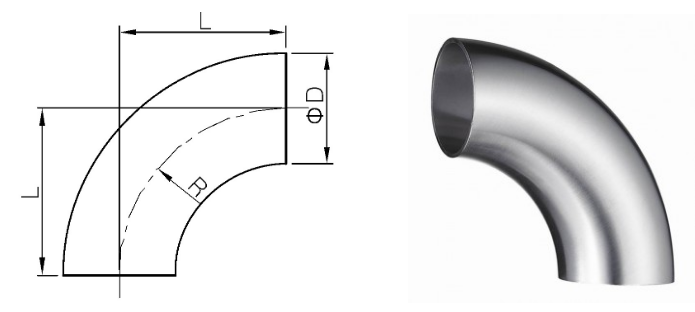

Dimension of Sanitary Weld Elbow 90 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1/1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

Dimension of Sanitary Weld elbow 90 degree -DIN (Unit:mm)

| SIZE | D | L | R |

| DN10 | 12 | 26 | 26 |

| DN15 | 18 | 35 | 35 |

| DN20 | 22 | 40 | 40 |

| DN25 | 28 | 50 | 50 |

| DN32 | 34 | 55 | 55 |

| DN40 | 40 | 60 | 60 |

| DN50 | 52 | 70 | 70 |

| DN65 | 70 | 80 | 80 |

| DN80 | 85 | 90 | 90 |

| DN100 | 104 | 100 | 100 |

| DN125 | 129 | 187 | 187 |

| DN150 | 154 | 225 | 225 |

| DN200 | 204 | 300 | 300 |

Dimension of Sanitary Weld elbow 90 degree -ISO/IDF (Unit:mm)

| SIZE | D | L | R |

| 12.7 | 12.7 | 19.1 | 19.1 |

| 19 | 19.1 | 28.5 | 28.5 |

| 25 | 25.4 | 33.5 | 33.5 |

| 32 | 31.8 | 38 | 38 |

| 38 | 38.1 | 48.5 | 48.5 |

| 45 | 45 | 57.5 | 57.5 |

| 51 | 50.8 | 60.5 | 60.5 |

| 57 | 57 | 68 | 68 |

| 63 | 63.5 | 83.5 | 83.5 |

| 76 | 76.2 | 88.5 | 88.5 |

| 89 | 89 | 103.5 | 103.5 |

| 102 | 101.6 | 127 | 127 |

| 108 | 108 | 152 | 152 |

| 114.3 | 114.3 | 152 | 152 |

| 133 | 133 | 190 | 190 |

| 159 | 159 | 228.5 | 228.6 |

| 204 | 204 | 300 | 300 |

| 219 | 219 | 305 | 302 |

| 254 | 254 | 372 | 375 |

| 304 | 304 | 450 | 450 |

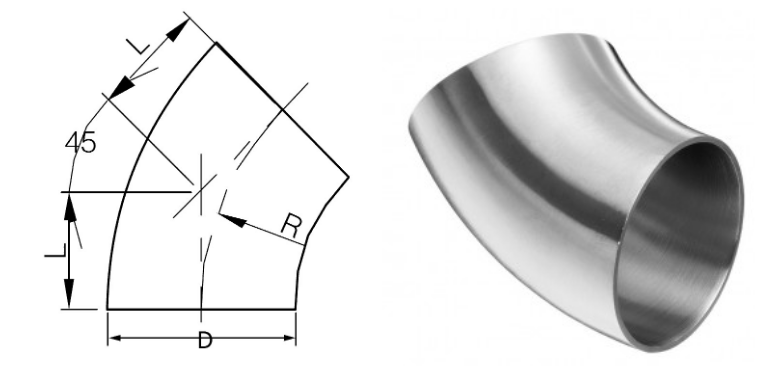

Dimension of Santitary Weld Elbow-45 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 7.9 | 19.1 |

| 3/4" | 19.1 | 11.8 | 28.5 |

| 1" | 25.4 | 15.8 | 38.1 |

| 1 1/4" | 31.8 | 69.7 | 47.7 |

| 1 1/2" | 38.1 | 74.1 | 57.2 |

| 2" | 50.8 | 103.2 | 76.2 |

| 2 1/2" | 63.5 | 131.8 | 95.3 |

| 3" | 76.2 | 160.3 | 114.3 |

| 4" | 101.6 | 211.1 | 152.4 |

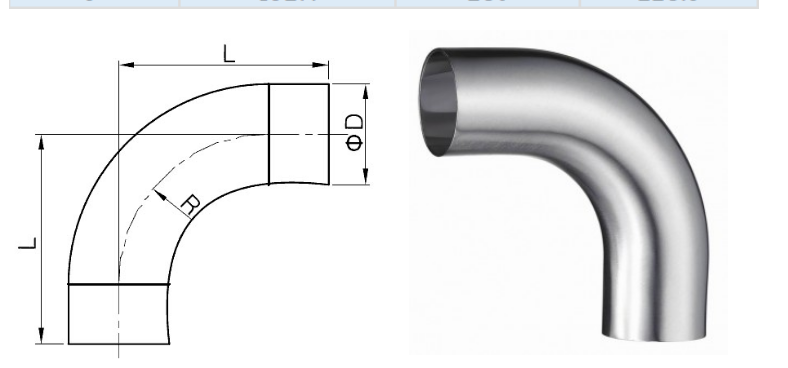

Dimension of Santitary Weld Elbow-90 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1 1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

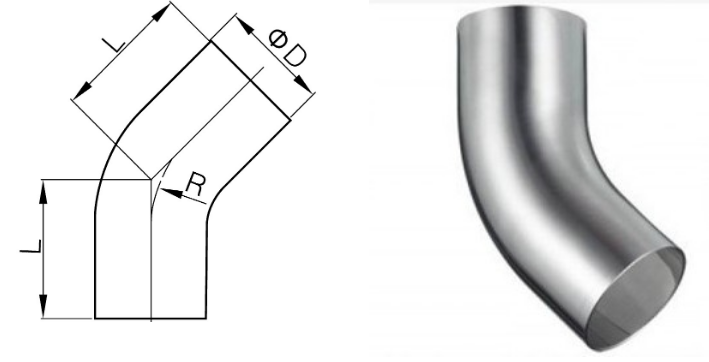

Dimension of Santitary Weld Elbow-45 degree With Straight Ends -SMS(Unit:mm)

| SIZE | D | L | R |

| 25 | 25.4 | 45 | 25 |

| 32 | 31.8 | 53.3 | 32 |

| 38 | 38.1 | 56.7 | 38 |

| 51 | 50.8 | 63.6 | 51 |

| 63 | 63.5 | 80.8 | 63.5 |

| 76 | 76.2 | 82 | 76 |

| 102 | 101.6 | 108.9 | 150 |

CHECKING

Material Specifications:

AISI 304 (CF8): 18-20% Chromium, 8-10.5% Nickel – Excellent general corrosion resistance

AISI 316/316L (CF3M): 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum – Superior chloride resistance

Material Certification: All materials supplied with EN 10204 3.1 certificates and full traceability

Low Carbon Variants: 316L (<0.03% C) available for applications requiring enhanced weldability

Sanitary Design Features:

Zero Dead Leg Design: Internal radii ≤1.5D per ASME BPE requirements

Crevice-Free Construction: Continuous polished surfaces with minimum 3mm radii

Drainable Geometry: Self-draining angles prevent liquid entrapment

Smooth Transitions: Gradual directional changes to minimize turbulence

Sterilizable: Validated for repeated steam sterilization cycles

Manufacturing Excellence:

Precision Forming: Cold forming or hydroforming for consistent wall thickness

Orbital Welding: For butt weld fittings, ensuring full penetration with minimal heat input

Progressive Polishing: Multi-stage mechanical polishing (180-600+ grit sequence)

Electropolishing: Optional electrochemical process for enhanced corrosion resistance

Passivation: Nitric acid treatment per ASTM A967 to restore chromium oxide layer

Connection Systems:

Tri-Clamp: Standard 1.5" clamp with polished 304/316 ferrules

Butt Weld: Prepared ends for orbital welding (ID/OD alignment within 0.1mm)

Bevel Seat: ISO-style connections with hygienic gasket retention

Quick Disconnect: Aseptic connections for frequent assembly/disassembly

Quality Marking & Traceability:

Laser Marking: Permanent marking with material grade, size, and lot number

Color Coding: Optional color bands for easy identification in mixed systems

RFID Tagging: Available for automated inventory and traceability systems

Application

Water Systems:

WFI (Water for Injection) and PW (Purified Water) distribution loops

Bioreactors:

Media preparation, harvest, and sample lines

Purification Systems:

Chromatography skids and ultrafiltration systems

Formulation:

Buffer preparation and product transfer lines

Clean Steam:

Condensate collection and distribution systems

Q: Can you accept TPI?

A: Yes, sure. Welcome visit our factory and come here to inspect the goods and inspect production process.

Q: Can you supply Form e, Certificate of origin?

A: Yes, we can supply.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you accept L/C deferred 30, 60, 90 days?

A: We can. Please negotiate with sales.

Q: Can you accept O/A payment?

A: We can. Please negotiate with sales.

Q: Can you supply samples?

A: Yes, some samples are free, please check with sales.

Q: Can you supply the products which comply with NACE?

A: Yes, we can.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.