Stainless Steel 304 and 316 Sanitary Pipe Fitting

Our Stainless Steel 304 and 316 Sanitary Pipe Fittings represent the gold standard in hygienic process piping systems for industries where purity, cleanability, and corrosion resistance are non-negotiable requirements. Engineered specifically for food, beverage, pharmaceutical, biotech, and cosmetic applications, these precision-manufactured elbows, tees, and complementary fittings provide seamless fluid transfer while maintaining the highest standards of sanitary integrity.

Manufactured from premium AISI 304 or superior 316/316L stainless steel, these fittings feature polished interior surfaces, crevice-free designs, and standardized connections that prevent bacterial growth and facilitate efficient Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures. With multiple connection options including sanitary clamp and orbital butt weld, they offer versatile solutions for both permanent and semi-permanent installations in critical process environments where product contamination must be absolutely prevented.

Data sheet

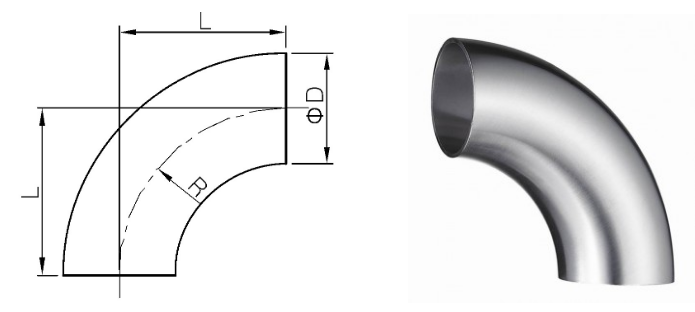

Dimension of Sanitary Weld Elbow 90 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1/1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

Dimension of Sanitary Weld elbow 90 degree -DIN (Unit:mm)

| SIZE | D | L | R |

| DN10 | 12 | 26 | 26 |

| DN15 | 18 | 35 | 35 |

| DN20 | 22 | 40 | 40 |

| DN25 | 28 | 50 | 50 |

| DN32 | 34 | 55 | 55 |

| DN40 | 40 | 60 | 60 |

| DN50 | 52 | 70 | 70 |

| DN65 | 70 | 80 | 80 |

| DN80 | 85 | 90 | 90 |

| DN100 | 104 | 100 | 100 |

| DN125 | 129 | 187 | 187 |

| DN150 | 154 | 225 | 225 |

| DN200 | 204 | 300 | 300 |

Dimension of Sanitary Weld elbow 90 degree -ISO/IDF (Unit:mm)

| SIZE | D | L | R |

| 12.7 | 12.7 | 19.1 | 19.1 |

| 19 | 19.1 | 28.5 | 28.5 |

| 25 | 25.4 | 33.5 | 33.5 |

| 32 | 31.8 | 38 | 38 |

| 38 | 38.1 | 48.5 | 48.5 |

| 45 | 45 | 57.5 | 57.5 |

| 51 | 50.8 | 60.5 | 60.5 |

| 57 | 57 | 68 | 68 |

| 63 | 63.5 | 83.5 | 83.5 |

| 76 | 76.2 | 88.5 | 88.5 |

| 89 | 89 | 103.5 | 103.5 |

| 102 | 101.6 | 127 | 127 |

| 108 | 108 | 152 | 152 |

| 114.3 | 114.3 | 152 | 152 |

| 133 | 133 | 190 | 190 |

| 159 | 159 | 228.5 | 228.6 |

| 204 | 204 | 300 | 300 |

| 219 | 219 | 305 | 302 |

| 254 | 254 | 372 | 375 |

| 304 | 304 | 450 | 450 |

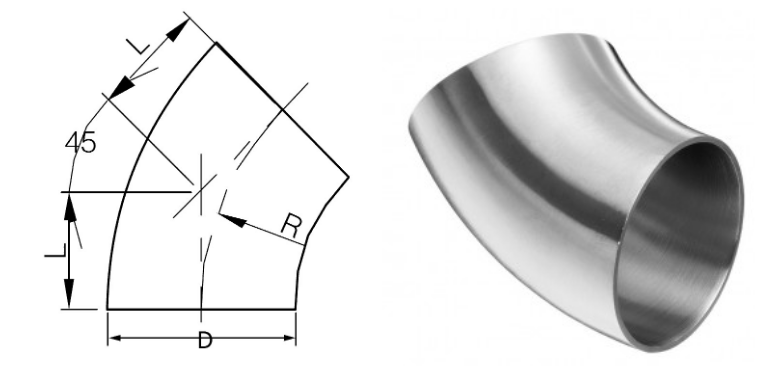

Dimension of Santitary Weld Elbow-45 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 7.9 | 19.1 |

| 3/4" | 19.1 | 11.8 | 28.5 |

| 1" | 25.4 | 15.8 | 38.1 |

| 1 1/4" | 31.8 | 69.7 | 47.7 |

| 1 1/2" | 38.1 | 74.1 | 57.2 |

| 2" | 50.8 | 103.2 | 76.2 |

| 2 1/2" | 63.5 | 131.8 | 95.3 |

| 3" | 76.2 | 160.3 | 114.3 |

| 4" | 101.6 | 211.1 | 152.4 |

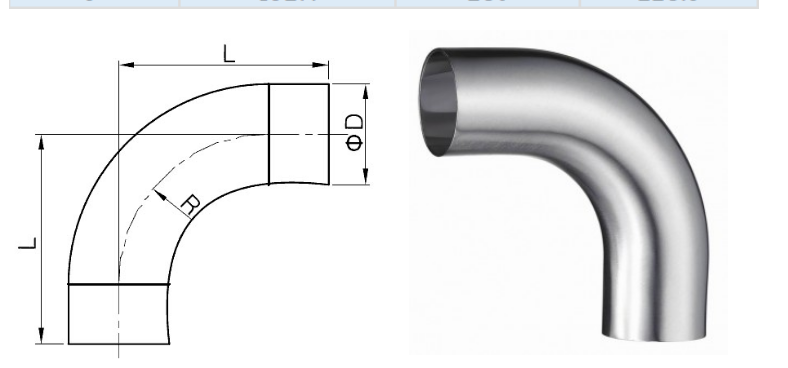

Dimension of Santitary Weld Elbow-90 degree -3A (unit:mm)

| SIZE | D | L | R |

| 1/2" | 12.7 | 19.1 | 19.1 |

| 3/4" | 19.1 | 28.5 | 28.5 |

| 1" | 25.4 | 38.1 | 38.1 |

| 1 1/4" | 31.8 | 47.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 57.2 |

| 2" | 50.8 | 76.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 95.3 |

| 3" | 76.2 | 114.3 | 114.3 |

| 4" | 101.6 | 152.4 | 152.4 |

| 6" | 152.4 | 228.6 | 228.6 |

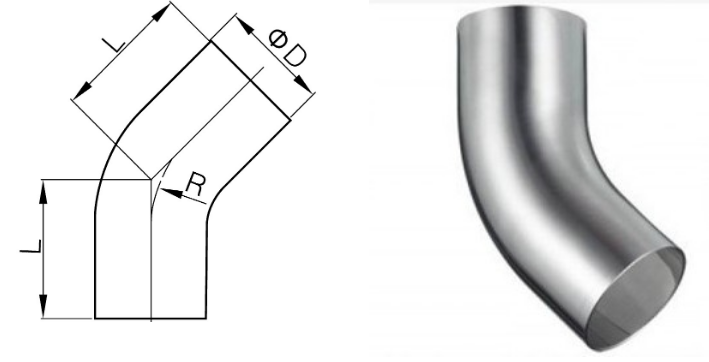

Dimension of Santitary Weld Elbow-45 degree With Straight Ends -SMS(Unit:mm)

| SIZE | D | L | R |

| 25 | 25.4 | 45 | 25 |

| 32 | 31.8 | 53.3 | 32 |

| 38 | 38.1 | 56.7 | 38 |

| 51 | 50.8 | 63.6 | 51 |

| 63 | 63.5 | 80.8 | 63.5 |

| 76 | 76.2 | 82 | 76 |

| 102 | 101.6 | 108.9 | 150 |

CHECKING

Material Excellence & Selection:

Each fitting is crafted from certified 304 (CF8) or 316/316L (CF8M) stainless steel. Grade 304 provides excellent general corrosion resistance for most sanitary applications, while Grade 316 with its 2-3% molybdenum content offers superior protection against chlorides and harsh cleaning chemicals, making it ideal for marine environments and aggressive CIP solutions. All materials are sourced with full traceability and mill certification to ensure compliance with FDA and regulatory requirements.

Precision Manufacturing Process:

Fittings undergo sophisticated manufacturing processes including CNC machining, precision forming, and specialized welding techniques. The manufacturing ensures:

Zero Dead Legs: All internal radii are designed to prevent product entrapment

Smooth Transitions: Seamless flow paths with no abrupt directional changes

Crevice-Free Construction: Eliminates potential bacterial harborage points

Concentric Alignment: Perfect alignment between connected components

Surface Finishing Technology:

Mechanical Polishing: Multi-stage progressive polishing from 180 to 600+ grit

Electropolishing: Electrochemical process that removes surface imperfections and enhances the passive chromium oxide layer

Passivation: Nitric acid treatment per ASTM A967 to maximize corrosion resistance

Final Cleaning: Ultrasonic cleaning in validated cleanroom environments

Connection Systems:

Sanitary Clamp (Tri-Clamp): Standard 1.5" clamp width with polished ferrule ends

Orbital Butt Weld: For permanent, flush internal welds in high-purity systems

Bevel Seat: ISO-style connections with hygienic gasket systems

Quick Disconnect: For frequent assembly/disassembly requirements

Certification

All fittings undergo final cleaning and packaging in ISO Class 7 (10,000) cleanroom environments:

Final Cleaning: Ultrasonic cleaning with high-purity solvents

Passivation: Nitric acid treatment and neutralization

Drying: Forced nitrogen drying to prevent water spots

Bagging: Individual heat-sealing in static-dissipative polyethylene bags

Gas Flushing: Nitrogen purging for oxygen-sensitive applications

Hygienic Packaging Materials:

Primary Packaging: Medical-grade, non-shedding polyethylene bags

Secondary Packaging: Double-walled corrugated boxes with virgin fiber content

Protective Materials: Custom foam inserts and dividers

Identification: Chemical-resistant labels with lot traceability

Shipping & Logistics:

Clean Transport: Dedicated clean shipping containers with humidity control

Temperature Monitoring: Data loggers for temperature-sensitive shipments

Documentation: Complete sanitary documentation package including:

Certificate of Sanitary Conformity

Cleanroom Packaging Certificate

Material Safety Data Sheets (MSDS)

Customs documentation with sanitary classification

Global Distribution Network:

Regional Warehouses: Stocking programs in major pharmaceutical hubs

Expedited Shipping: Air freight with temperature-controlled options

Bulk Shipments: Dedicated container programs with clean loading protocols

Q: Can you accept TPI?

A: Yes, sure. Welcome visit our factory and come here to inspect the goods and inspect production process.

Q: Can you supply Form e, Certificate of origin?

A: Yes, we can supply.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you accept L/C deferred 30, 60, 90 days?

A: We can. Please negotiate with sales.

Q: Can you accept O/A payment?

A: We can. Please negotiate with sales.

Q: Can you supply samples?

A: Yes, some samples are free, please check with sales.

Q: Can you supply the products which comply with NACE?

A: Yes, we can.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

A249 stainless steel seamless pipe thickness 1....

-

304 Round Stainless Steel Pipe seamless White S...

-

SUS 304 321 316 180 Degree Stainless steel pipe...

-

Stainless Steel Elbow Compression Fittings Inst...

-

ANSI B16.9 butt weld Pipe Fitting carbon steel ...

-

WN ANSI B16.36 orifice weld neck flange with ja...