304/316L Hot Induction Bending Seamless 90-Degree Pipe Bends

We specialize in manufacturing high-precision stainless steel long-radius pipe bends, engineered for demanding industrial applications where fluid dynamics, structural integrity, and long-term reliability are paramount. Our product range includes seamless 90-degree pipe bends fabricated through advanced hot induction bending technology, available in standard radius configurations of 1D, 1.5D, 3D, and 5D, utilizing premium-grade 304 and 316L stainless steel materials. These components are critical in systems requiring minimal pressure drop, reduced turbulence, and enhanced flow characteristics, making them ideal for chemical processing, petrochemical, power generation, and high-purity applications.

PRODUCT PARAMETERS

| Product Name | Hot induction bend |

| Size | 1/2"-36" seamless, 26"-110" welded |

| Standard | ANSI B16.49, ASME B16.9 and customized etc |

| Wall thickness | STD, XS, SCH20,SCH30,SCH40, SCH60, SCH80,SCH100 ,SCH120,SCH140, SCH160, XXS ,customized, etc. |

| Elbow | 30° 45° 60° 90° 180°,etc |

| Radius | multiplex radius, 3D and 5D is more popular, also can be 4D, 6D, 7D, 10D,20D, customized, etc. |

| End | Bevel end/BE/buttweld, with or with tangent(straight pipe on each end) |

| Surface | polished, Solid solution heat treatment, anneal, pickled , etc. |

| Material | Stainless steel:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317,

904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc |

| Duplex steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Nickel alloy steel: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276,Monel400,Alloy20 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

Technical Specifications and Design Parameters

1D Radius Bends

Radius Definition: Bend radius equal to the nominal pipe diameter (1 × D)

Typical Applications: Compact piping layouts, space-constrained installations, and systems requiring tight turning angles

Flow Characteristics: Higher pressure drop compared to longer radii, suitable for moderate flow velocities

Standards Compliance: ASME B16.9, MSS SP-75, ISO 15590-2

1.5D Radius Bends

Radius Definition: Bend radius equal to 1.5 times the nominal pipe diameter

Typical Applications: General industrial piping, HVAC systems, and moderate-pressure process lines

Flow Characteristics: Balanced compromise between space efficiency and flow optimization

Standards Compliance: ASME B16.9, ASTM A403, EN 10253-2

3D Radius Bends

Radius Definition: Bend radius equal to 3 times the nominal pipe diameter

Typical Applications: High-pressure systems, slurry transportation, and erosive/corrosive fluid handling

Flow Characteristics: Significantly reduced turbulence and pressure drop, minimizing erosion potential

Standards Compliance: ASME B16.49, API 5L, ISO 15590-1

5D Radius Bends

Radius Definition: Bend radius equal to 5 times the nominal pipe diameter

Typical Applications: Critical process systems, high-purity applications, and systems requiring minimal flow disturbance

Flow Characteristics: Optimal flow dynamics with virtually no turbulence, ideal for sensitive processes

Standards Compliance: ASME B16.49, ASTM A234, special customer specifications

Process Advantages

Material Integrity Preservation:

Controlled heating prevents metallurgical degradation

Wall Thickness Consistency:

Advanced tooling maintains uniform thickness throughout bend

Surface Quality:

Minimized oxidation through controlled atmosphere or subsequent pickling

Dimensional Accuracy:

CNC-controlled process ensures precise radius and angle control

Grain Structure Optimization:

Proper heating and cooling cycles maintain optimal material properties

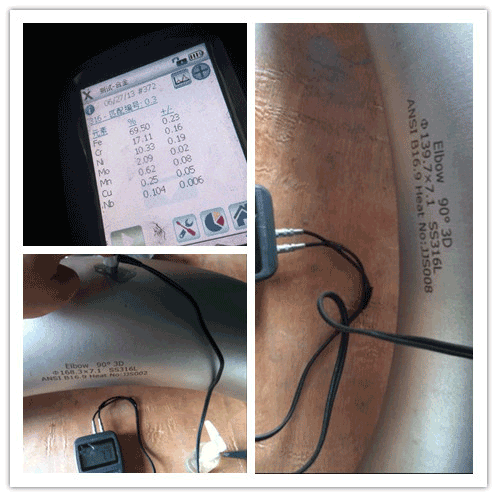

INSPECTION

Pre-process Verification:

Material certification and dimensional validation

In-process Monitoring:

Temperature control, bending rate monitoring, and real-time dimensional checks

Post-process Inspection:

Ultrasonic thickness testing, dimensional verification, surface quality assessment

Final Testing:

Hydrostatic testing, visual inspection, and documentation completion

PACKAGING & SHIPPING

Protective Packaging

Individual wrapping with VCI protection

Wooden crates for international shipments

Protective end caps

Clear identification and marking

Proper documentation

Shipping Considerations

Proper bracing and securing

Weather protection

Documentation completeness

Timely delivery coordination

Global logistics capability

Black steel pipe bend

Beside while steel pipe bend, also can produce black steel pipe bend,more details, please click followed link.

Carbon steel, Cr-mo alloy steel and low termperature carbon steel are also avaiable

Our stainless steel long-radius pipe bends represent the intersection of advanced manufacturing technology, material science excellence, and practical engineering application. Through precise control of the hot induction bending process and utilization of premium 304 and 316L stainless steels, we deliver components that provide reliable performance in the world's most demanding industrial environments.

The combination of multiple radius options (1D, 1.5D, 3D, 5D) with the superior corrosion resistance of stainless steel makes these bends ideal for applications ranging from chemical processing to power generation, pharmaceutical manufacturing to offshore oil production. Each bend undergoes rigorous quality control to ensure it meets both industry standards and specific customer requirements.

FAQ

1. What are SUS 304, 321, and 316 stainless steel elbows?

SUS 304, 321 and 316 are different grades of stainless steel commonly used in the manufacture of bent pipes. They have excellent corrosion resistance and high strength properties.

2. What is a 180 degree elbow?

A 180 degree elbow is a bend fitting used to redirect the flow of fluid or gas in a pipe 180 degrees. It allows for smooth flow while avoiding any sudden changes in direction.

3. What are the applications of SUS 304, 321, and 316 stainless steel elbows?

These stainless steel elbows are widely used in various industries such as chemical processing, oil and gas, petrochemicals, power generation, pharmaceuticals and food processing.

4. What are the advantages of using SUS 304, 321, and 316 stainless steel elbows?

SUS 304, 321 and 316 stainless steel elbows have excellent corrosion resistance, high temperature resistance and pressure resistance. They retain their strength even under extreme conditions, ensuring a long service life.

5. Can SUS 304, 321, and 316 stainless steel elbows be welded?

Yes, these stainless steel elbows can be easily welded using proper welding techniques and equipment. However, it is important to follow proper welding procedures to ensure the integrity of the joint.

6. Are there different sizes for SUS 304, 321 and 316 stainless steel elbows?

Yes, SUS 304, 321 and 316 stainless steel elbows are available in various sizes to accommodate different pipe diameters and wall thicknesses. They can be customized to suit specific project requirements.

7. Are SUS 304, 321 and 316 stainless steel elbows suitable for high pressure applications?

Yes, these stainless steel elbows are designed to withstand high pressure conditions. They have excellent mechanical properties and can withstand high pressures without deformation or failure.

8. Can SUS 304, 321, and 316 stainless steel elbows be used in corrosive environments?

Absolutely! SUS 304, 321 and 316 stainless steel offer excellent corrosion resistance and are ideal for use in corrosive environments, including exposure to chemicals, acids and salt water.

9. Are SUS 304, 321, and 316 stainless steel elbows easy to maintain?

Yes, SUS 304, 321 and 316 stainless steel elbows are relatively easy to maintain. Regular cleaning and inspections can help identify any signs of corrosion or damage so that repairs or replacements can be made if needed.

10. Where can I buy SUS 304, 321, and 316 stainless steel elbow pipes?

SUS 304, 321 and 316 stainless steel elbows can be purchased from various suppliers, distributors or manufacturers that specialize in stainless steel pipe fittings. It is important to choose a reputable supplier that offers high-quality products.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.