Orifice Flange Forged Stainless Steel Flange 304/316L

The Standard Pressure Orifice Flange manufactured from forged 304/316L stainless steel represents a precision-engineered flow measurement component designed for critical process applications. These flanges are specifically engineered to provide accurate, reliable, and repeatable flow measurement in industrial piping systems while maintaining structural integrity under varying pressure conditions. Manufactured through advanced forging processes and precision machining, our orifice flanges ensure optimal performance in corrosive and high-purity applications where material integrity and dimensional accuracy are paramount.

Class 150: Suitable for low-pressure applications (275 psi at 100°F)

Class 300: Medium-pressure applications (720 psi at 100°F)

Class 600: High-pressure applications (1,440 psi at 100°F)

Class 900: Very high-pressure applications (2,160 psi at 100°F)

Temperature Compensation: Full pressure-temperature ratings available for elevated temperature applications

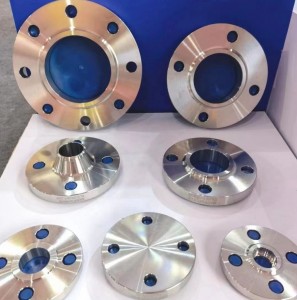

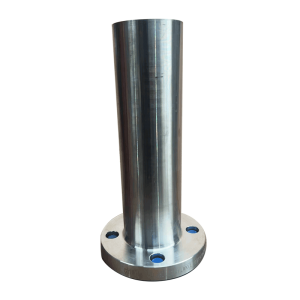

PRODUCTS DETAIL SHOW

Primary Standards:

ASME B16.36, ASME B16.5, API 6A

Secondary Standards:

MSS SP-44, ISO 7005-1, DIN 2527

Pressure-Temperature Ratings:

Fully compliant with ASME B16.5 Table 2-1.1

Material Standards:

ASTM A182 F304/F304L, F316/F316L

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

Manufacturing Process: Precision Forging Technology

Closed-Die Forging Process

- Material Selection: Premium-grade stainless steel billets with full traceability

- Heating Process: Controlled induction heating to 1150-1260°C

- Forging Operation: Multi-stage forging under 2,500-6,000 ton presses

- Grain Flow Optimization: Directional grain flow for enhanced mechanical properties

- Scale Removal: High-pressure water descaling for clean surfaces

Heat Treatment Protocol

- Solution Annealing: Heating to 1010-1120°C followed by rapid quenching

- Stress Relieving: For complex geometries and heavy sections

- Tempering: When required for specific mechanical properties

- Quenching Mediums: Water, oil, or air according to material requirements

Precision Machining Operations

- CNC Turning: Primary face and bore machining

- Bolt Hole Drilling: Precision drilling with carbide tooling

- Face Milling: Serrated finish (125-250 AARH) for optimal gasket seating

- Orifice Bore Machining: Micro-tolerance boring (±0.001 inches)

- Final Inspection: Comprehensive dimensional verification

Q: Can you accept TPI?

A: Yes, sure. Welcome visit our factory and come here to inspect the goods and inspect production process.

Q: Can you supply Form e, Certificate of origin?

A: Yes, we can supply.

Q: Can you supply invoice and CO with chamber of commerce?

A: Yes, we can supply.

Q: Can you accept L/C deferred 30, 60, 90 days?

A: We can. Please negotiate with sales.

Q: Can you accept O/A payment?

A: We can. Please negotiate with sales.

Q: Can you supply samples?

A: Yes, some samples are free, please check with sales.

Q: Can you supply the products which comply with NACE?

A: Yes, we can.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.