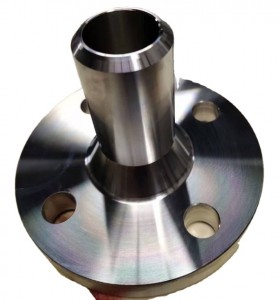

WN ANSI B16.36 Orifice Weld Neck Flange

The WN ANSI B16.36 Orifice Weld Neck Flange with Jack Screw is a precision-engineered flow measurement component designed for critical process applications.

This specialized flange integrates an integral neck for optimal stress distribution with strategically placed jack screws for safe and efficient orifice plate installation and maintenance.

Manufactured in compliance with ASME/ANSI B16.36 standards, this flange ensures accurate flow measurement while maintaining structural integrity in high-pressure piping systems.

SPECIFICATION

|

Product Name

|

weld neck Orifice flange

|

|||

|

SIZE

|

1" up ro 24"

|

|||

|

Pressure

|

150#-2500#

|

|||

|

Standard

|

ANSI B16.36

|

|||

|

Wall thickness

|

SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc.

|

|||

|

Material

|

Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S,

A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. Carbon steel: A105, A350LF2, Q235, St37, St45.8, A42CP, E24 , A515 Gr60, A515 Gr 70 |

|||

|

Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 ,

UNS32760, 1.4462,1.4410,1.4501 and etc. Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. |

||||

|

Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,

C22, C-276, Monel400, Alloy20 etc. Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 etc. |

||||

|

Application

|

Petrochemical industry;avation and aerospace industry;pharmaceutical industry;

gas exhaust;power plant;ship building;water treatment,etc. |

|||

|

Advantages

|

ready stock,faster delivery time;available in all sizes,customized;high quality

|

|||

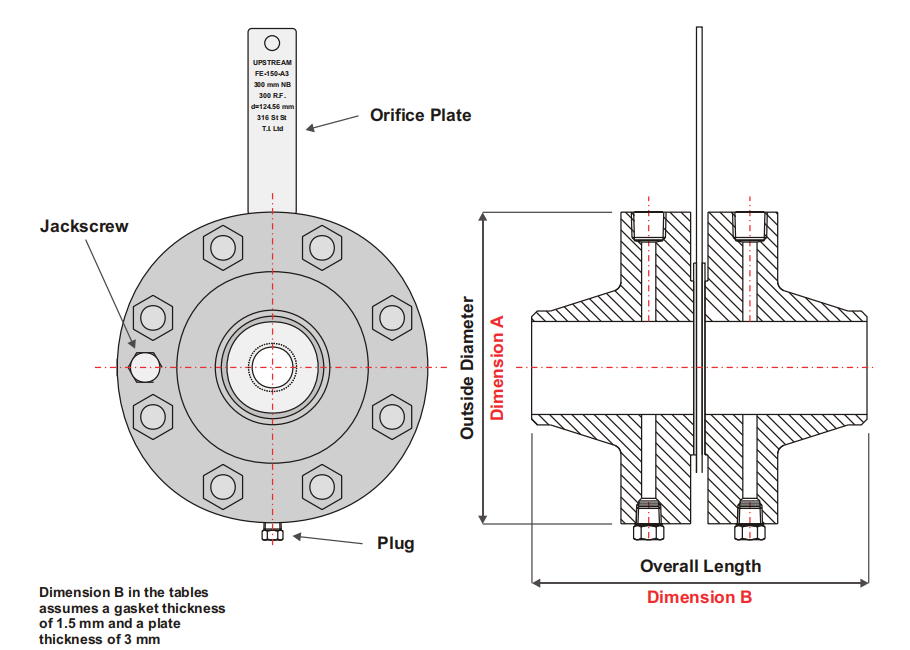

Weld Neck Configuration: Provides maximum structural integrity through tapered hub design

Integrated Jack Screws: Equipped with minimum 2 jack screws (90° apart) for safe orifice plate handling

Orifice Bore: Precision-machined according to specified bore size and tolerance

Raised Face: Standard 1/16" raised face for gasket retention (other faces available)

Bolt Circle: Precision-drilled bolt holes with smooth finish for easy alignment

Material Grade: Available in carbon steel, stainless steel, alloy steel, and special alloys

DIMENSION STANDARDS

PRODUCTS DETAIL SHOW

1.Materials

Carbon Steel: ASTM A105, A350 LF2

Stainless Steel: ASTM A182 F304/304L, F316/316L, F321

Alloy Steel: ASTM A182 F11, F22, F91

Special Alloys: Monel, Inconel, Hastelloy available upon request

2.Technical Specifications

Pressure Ratings: Class 150, 300, 400, 600, 900, 1500, 2500

Size Range: 1/2" to 24" NPS (Nominal Pipe Size)

Standards Compliance: ASME/ANSI B16.36, ASME/ANSI B16.5, MSS SP-44

Orifice Bore Tolerance: ±0.001" for precise flow measurement

Jack Screw Specifications: Typically 1/2" - 13 UNC, heat-treated alloy steel

Face Finish: 125-250 AARH serrated finish for optimal gasket seating

Dimensions: Compliant with ASME B16.36 dimensional requirements

3.Quality Assurance

Material Traceability: Full heat number tracking from raw material to finished product

Dimensional Verification: 100% inspection of critical dimensions

Pressure Testing: Optional hydrostatic testing available

Documentation: Mill test certificates, material certificates, inspection reports

Marking: Standard compliant permanent marking including material grade, size, and heat number

Marking And Testing

1. Forging: Die-forged for superior grain structure

2. Heat Treatment: Normalized and tempered for optimal mechanical properties

3. Machining: CNC precision machining for dimensional accuracy

4. Quality Control: 100% dimensional verification and material certification

5. Surface Treatment: Rust-preventive coating or electroplating as specified

Packaging And Shipping

1. Protection: Individual wrapping with anti-corrosion coating

2. Handling: Wooden crates with proper bracing for international shipping

3. Identification: Clear marking with material specification and size

4. Certification: Complete documentation package included with shipment

5. Lead Time: Standard 1-3 weeks, expedited delivery available

COOPERATION CASE

This order is for Vietnam stockist

PRODUCTION PROCESS

Applications

Oil & Gas Production: Flow measurement in crude oil and natural gas pipelines

Refinery Operations: Process control in distillation units and catalytic crackers

Chemical Processing: Accurate dosing and batching in reactor feed systems

Power Generation: Steam flow measurement in boiler feed and turbine systems

Water Treatment: Chemical injection control and flow monitoring

Pharmaceutical: Precise fluid control in batch processing operations

This comprehensive product specification ensures optimal performance in flow measurement applications while maintaining the highest standards of safety and reliability.

The integrated jack screw feature significantly reduces maintenance time and improves operational safety during orifice plate replacement procedures.

We are committed to providing customers with high-quality products and professional services, ensuring each flange delivers reliable performance under demanding operating conditions.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.