Carbon Steel Low-Temperature Seamless Elbows

Engineered for critical service in cryogenic and low-temperature environments, our Carbon Steel Low-Temperature Seamless Elbows are manufactured from high-grade materials like API 5L X65 or specialized ASTM A333 Grade 6 steel. Available in both 90° and 180° configurations with a standard 1.5D Long Radius, these butt weld elbows are designed to maintain exceptional toughness and structural integrity under extreme sub-zero conditions, preventing brittle fracture in applications such as LNG processing, cryogenic storage, and arctic pipeline systems.

Manufactured through a seamless hot-forming process, these elbows offer superior metallurgical continuity and pressure integrity compared to welded counterparts. The 1.5D bend radius ensures smooth flow with minimal turbulence and pressure drop, while the precise weld bevel preparation guarantees high-quality, full-penetration field welds. These components are the reliable choice for engineers designing safe and durable piping systems that must operate reliably from ambient down to frigid temperatures.

PRODUCT PARAMETERS

| Product Name | Pipe elbow |

| Size | 1/2"-36" seamless elbow(SMLS elbow), 26"-110" welded with seam. Biggest outside diameter can be 4000mm |

| Standard | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Degree | 30° 45° 60° 90° 180°,etc |

| Radius | LR/long radius/R=1.5D,SR/Short radius/R=1D |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 , 12crmov, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

PIPE FITTINGS

Butt welded pipe fittings includes steel pipe elbow, steel pipe tee, steel pipe reduer, steel pipe cap. All those butt welding pipe fittings, we can supply together, we have more 20 years production experiences.

If you are also interested other fittings, please click followed LINK to check details.

PIPE TEE PIPE REDUCER PIPE CAP PIPE BEND FORGED FITTINGS

BUTT WELDED PIPE ELBOW

Steel pipe elbow is a key parts in a piping system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

For industrial pipe elbow, the connectin end type is butt weld, according to ANSI B16.25. Butt welded can described butt welding, buttweld, bevel end. BW

ELBOW TYPE

Elbow could be ranged from direction angle, connection types, length and radius, material types.

Classified by Direction Angle

As we know, according to fluid direction of the pipelines, elbow can be divided into different degrees, such as 45 degree, 90 degree,180 degree, which are most common degrees. Also there has 60 degree and 120 degree, for some special pipelines.

For 90 degree elbow, also described 90d elbow, or 90 deg elbow.

What is Elbow Radius

The elbow radius mean curvature radius. If the radius is the same as pipe diameter, it called short radius elbow, also called SR elbow, normally for low pressure and low speed pipelines.

If the radius is larger than pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high pressure and high flow rate pipelines.

If radius more than 1.5D, always named bend. elbow bend pipe fittings. Such as 2d elbow, 2d bend, 3d elbow, 3d bend, etc.

Classification by Material

Carbon steel, also called mild steel or black steel. Such as ASTM A234 WPB

Looking for stainless steel elbows, please click this link to find more details: STAINLESS STEEL ELBOWS

Shape Type

Can be equal elbow or Reducing elbow

ELBOW SURFACE

Sand Blast

After hot forming, we arrange sand blast to make the surface to be clean and smooth.

After Sand blast, to avoid get rust, should do black painting or anti-rust oil, Hot dip galvanized (HDG) , epoxy, 3PE, vanished surface, etc. That is depend on customer's request.

Material & Metallurgy:

Elbows are fabricated from seamless pipe certified to API 5L X65 for high-strength applications or ASTM A333 Grade 6 for guaranteed low-temperature impact properties. These steels are fine-grained, fully killed, and often normalized to achieve the necessary Charpy V-Notch (CVN) impact energy values at the specified minimum design temperature. The chemistry is controlled to limit elements that promote brittleness, ensuring excellent fracture toughness in cold climates.

Seamless Manufacturing Process:

The elbows are formed using controlled hot induction bending of seamless pipe or the hot pushing process. Both methods preserve the material's homogeneity without creating a longitudinal seam. Post-forming, elbows undergo normalizing heat treatment to refine the grain structure, relieve stresses, and restore the mechanical properties crucial for low-temperature performance.

Precision Engineering & Dimensions:

Strictly manufactured to ASME B16.9 tolerances.

Center-to-End / Center-to-Center Dimensions: Precisely controlled for accurate piping layout.

Wall Thickness Control: The process ensures uniform thickness. Special attention is given to the extrados (outer bend) to keep thinning within ASME B16.9 allowable limits (typically max 12.5%).

Out-of-Roundness & Bevel: Ends are machined to ensure roundness for perfect fit-up. A consistent 37.5° welding bevel with a 1.6mm land is prepared on both ends.

Marking & Traceability:

Each elbow is permanently stamped per ASTM A960, including: Material Specification (e.g., API 5L X65 or A333 Gr.6), Heat Number, Size, Wall Schedule, Manufacturer's ID, and a "LT" (Low Temperature) identifier. This ensures full traceability from the steel mill to the finished product.

HEAT TREATMENT

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO.

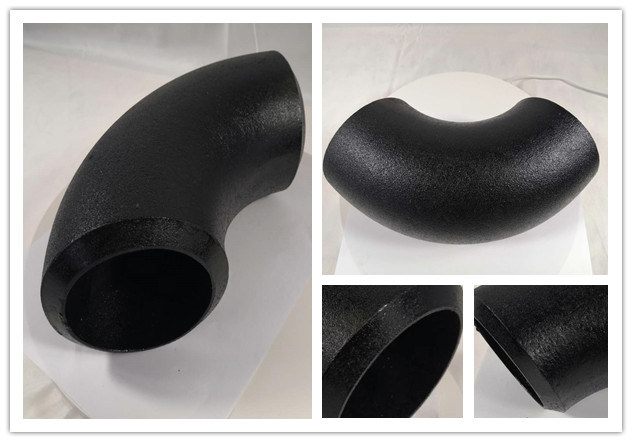

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Sand blast first, then Perfect painting work. Also can be varnished.

3. Without lamination and cracks.

4. Without any weld repairs.

INSPECTION

Each heat of steel is supplied with a full Mill Test Certificate (MTC 3.2) detailing chemistry and mechanical properties. We perform Positive Material Identification (PMI) and ultrasonic thickness checks on raw pipe. The core verification is Charpy V-Notch Impact Testing per ASTM A370. Sets of three specimens are tested at the minimum design temperature (e.g., -46°C) to ensure the absorbed energy meets or exceeds specified requirements (e.g., ≥ 20J or 27J average per ASTM A333).

PACKAGING& SHIPPING

To prevent corrosion during transit, beveled ends and exposed surfaces are coated with a temporary, easily removable rust preventive. Each elbow is then wrapped in VCI (Vapor Corrosion Inhibitor) film or heavy-duty plastic. For heavy or large-diameter elbows, wooden cradles or custom crates are used to provide structural support and prevent deformation.

We utilize various modes based on order size and urgency: air freight for expedited critical items, sea container (FCL/LCL) for bulk orders, and flat-rack containers for oversized elbows. All shipping documents (Packing List, Commercial Invoice, Certificate of Origin, and full Test Package) are prepared to facilitate smooth customs clearance for industrial projects worldwide.

Application

Oil & Gas (Arctic & Offshore):

Subsea pipelines, offshore production platforms in cold regions, and onshore gathering systems in arctic climates.

LNG (Liquefied Natural Gas) Industry:

Cold boxes, liquefaction process lines, LNG transfer lines, and storage tank piping operating at cryogenic temperatures.

Cryogenic Processing:

Industrial gas plants (O2, N2, Ar separation), ethylene plants, and CO2 transportation pipelines.

Power & Chemical:

Process lines in facilities located in extreme cold environments.

Specialization in Low-Temperature Materials:

We possess deep expertise in the specifications, testing, and handling of low-temperature carbon steels, ensuring the product delivers guaranteed performance.

Seamless Manufacturing Focus:

Our commitment to seamless production guarantees the highest integrity for critical cryogenic service where weld flaws are unacceptable.

Comprehensive Certification Package:

We provide the most rigorous documentation in the industry, especially the certified Charpy Impact Test Reports, which are essential for engineering approval and safety audits in low-temperature projects.

Project-Based Customization:

We tailor products to specific project requirements, including special sizes, enhanced impact testing temperatures, and supplementary NDT, serving EPC contractors and end-users directly.

Global Logistics for Critical Infrastructure: We are experienced partners in major energy projects, ensuring these specialized, certified components are delivered on schedule to remote or demanding locations, supported by complete traceability and quality documentation.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

ANSI b16.9 36 inch schedule 40 Butt Weld carbon...

-

Asme b16.9 schedule 80 steel pipe fittings tee ...

-

carbon steel 45 degree bend 3d bw 12.7mm WT AP...

-

SUS304 316 pipe fittings Stainless steel elbow ...

-

ANSI B16.9 Carbon Steel 45 Degree Welding Bend

-

ANSI B16.9 butt weld Pipe Fitting carbon steel ...