PRODUCT PARAMETERS

| Product Name | Pipe tee |

| Size | 1/2"-24" seamless, 26"-110" welded |

| Standard | ANSI B16.9, EN10253-2, DIN2615, GOST17376, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

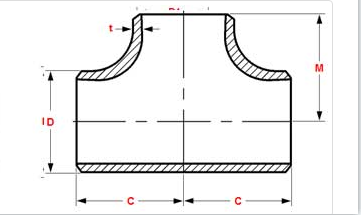

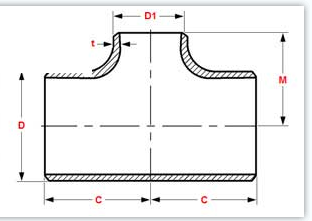

| Type | equal/straight, unequal/reducing/reduced |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

TEE INTRODUCTION

Pipe Tee is a type of pipe fitting which is T-shaped having two outlets, at 90° to the connection to the main line. It is a short piece of pipe with a lateral outlet. Pipe Tee is used to connect pipelines with a pipe at a right angle with the line. Pipe Tees are widely used as pipe fittings. They are made of various materials and available in various sizes and finishes. Pipe tees are extensively used in pipeline networks to transport two-phase fluid mixtures.

TEE TYPE

- There are straight pipe tees which have the same size openings.

- Reducing pipe tees have one opening of different size and two openings of the same size.

-

DIMENSIONAL TOLERANCES OF ASME B16.9 STRAIGHT TEES

Nominal Pipe Size 1/2 to 2.1/2 3 to 3.1/2 4 5 to 8 10 to 18 20 to 24 26 to 30 32 to 48 Outside Dia

at Bevel (D)+1.6

-0.81.6 1.6 +2.4

-1.6+4

-3.2+6.4

-4.8+6.4

-4.8+6.4

-4.8Inside Dia at End 0.8 1.6 1.6 1.6 3.2 4.8 +6.4

-4.8+6.4

-4.8Center to End (C / M) 2 2 2 2 2 2 3 5 Wall Thk (t) Not less than 87.5% of Nominal Wall Thickness Dimensional tolerances are in millimeters unless otherwise indicated and are equal ± except as noted.

HEAT TREATMENT

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. MT, UT,PT, X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate

PACKAGING & SHIPPING

1. Packed by plywood case or plywood pallet as per ISPM15

2. we will put packing list on each package

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free

Heat treatment

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

Marking

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO

Detailed photos

1. Bevel end as per ANSI B16.25.

2. Sand blast first, then Perfect painting work. Also can be varnished

3. Without lamination and cracks

4. Without any weld repairs

-

ANSI B16.9 stainless steel 45 degree butt weld ...

-

Stainless Steel A403 WP316 Butt Weld Pipe Fitti...

-

carbon steel 90 Degree Black Steel Hot Inductio...

-

carbon steel sch80 butt welded end 12 inch sch4...

-

A234WPB black seamless steel pipe fitting unequ...

-

8 Inch stainless steel pipe cap pipe end cap he...