SPECIFICATION

|

Product Name

|

weld neck Orifice flange

|

|||

|

SIZE

|

1" up ro 24"

|

|||

|

Pressure

|

150#-2500#

|

|||

|

Standard

|

ANSI B16.36

|

|||

|

Wall thickness

|

SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc.

|

|||

|

Material

|

Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S,

A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. Carbon steel: A105, A350LF2, Q235, St37, St45.8, A42CP, E24 , A515 Gr60, A515 Gr 70 |

|||

|

Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 ,

UNS32760, 1.4462,1.4410,1.4501 and etc. Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. |

||||

|

Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,

C22, C-276, Monel400, Alloy20 etc. Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 etc. |

||||

|

Application

|

Petrochemical industry;avation and aerospace industry;pharmaceutical industry;

gas exhaust;power plant;ship building;water treatment,etc. |

|||

|

Advantages

|

ready stock,faster delivery time;available in all sizes,customized;high quality

|

|||

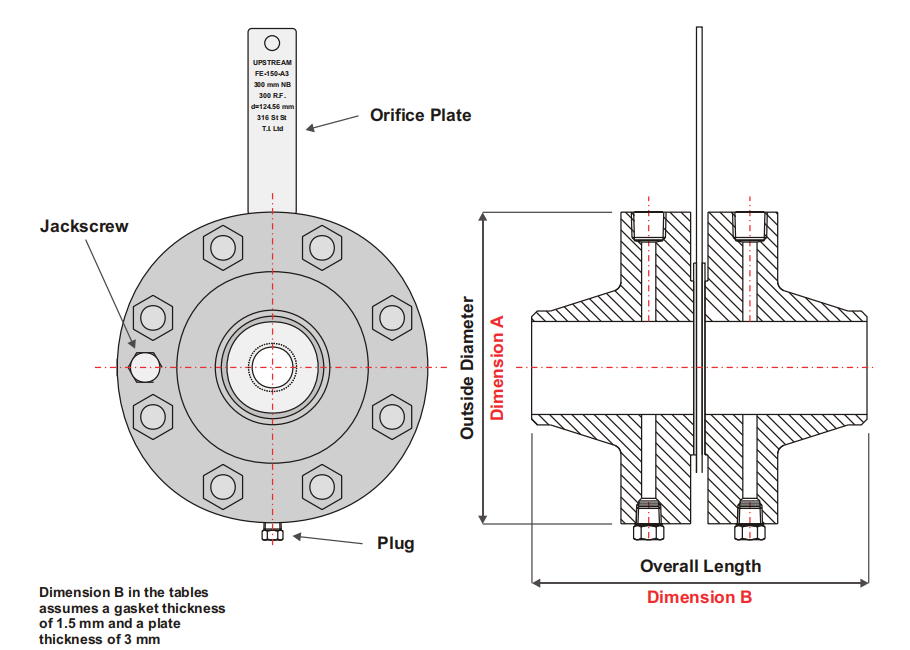

DIMENSION STANDARDS

PRODUCTS DETAIL SHOW

1. Materials

Thermocouple Instruments Ltd can supply

2.Pressure Tappings

3.Gaskets

Thermocouple Instruments Ltd is able to supply

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

COOPERATION CASE

This order is for Vietnam stockist

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

Introducing our high quality butt welded orifice flanges, designed to meet the demanding requirements of a variety of industrial applications. Our orifice flanges are designed to provide reliable, efficient solutions for measuring the flow of liquids, gases and steam in pipes.

Our butt weld orifice flanges are made from high quality materials and offer exceptional durability and corrosion resistance, making them suitable for use in harsh and corrosive environments. The precision machining of the flange ensures a perfect fit and tight seal, minimizing the risk of leakage and ensuring long-term performance.

The welded neck design of our orifice flanges creates a strong and secure connection to the piping system for enhanced stability and support. This design also helps reduce stress concentrations at flange connections, thereby improving the overall integrity of the system.

Our orifice flanges are available in a variety of sizes and pressure ratings to meet different application requirements. Whether used in the oil and gas, petrochemical, chemical processing or power generation industries, our weld neck orifice flanges provide consistent and accurate flow measurement.

In addition to their sturdy construction, our orifice flanges are easy to install and maintain, saving our customers valuable time and resources. The smooth surface finish and precise dimensions further enhance ease of handling and assembly.

We understand the critical role orifice plate flanges play in ensuring the efficiency and safety of industrial processes. That's why we're committed to providing products that meet the highest quality standards and performance specifications.

With our butt weld orifice flanges, you can trust that your flow measurement applications will benefit from reliable, long-lasting and accurate performance. Experience the difference with our top-of-the-line butt weld orifice plate flanges and increase the efficiency of your operations.

-

Stainless Steel 304 304L 316 316L ASTM forged t...

-

ANSI DIN Forged Class150 Stainless Steel Slip o...

-

ASTM A182 F51 F53 BL ANSI B16.5 Stainless steel...

-

Manufacturer specialized forging high-pressure ...

-

stainless steel Graphite Packing Spiral Wound G...

-

ASME B16.48 CL150 CL300 Paddle spacer plank fla...