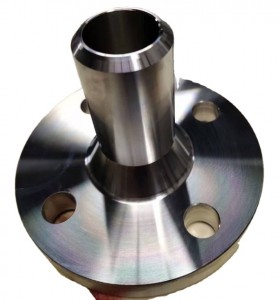

DN800 DIN EN1092-1 PN40/PN6 Carbon Steel Weld Neck Flange

The DN800 DIN EN1092-1 PN40/PN6 Carbon Steel Weld Neck Flange represents a critical component in large-diameter piping systems requiring superior structural integrity and reliable sealing performance. Manufactured to exacting European standards, this flange is engineered for high-pressure applications in industrial processes, combining the robust strength of carbon steel with precision machining to ensure optimal performance in demanding service conditions.

SPECIFICATION

| Product Name | Lap joint/Loose flange |

| Size | 1/2"-24" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5,EN1092-1, JIS B2220 etc. |

| Stub end | MSS SP 43, ASME B16.9 |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

Constructed from premium carbon steel P265GH, this weld neck flange delivers exceptional mechanical properties including minimum yield strength of 265 MPa and tensile strength of 410-530 MPa. The material's carefully controlled chemical composition provides excellent weldability, corrosion resistance, and durability across a temperature range from -20°C to +400°C.

DIMENSION STANDARDS

PRODUCTS DETAIL SHOW

Compliant with DIN EN1092-1 specifications, this flange meets rigorous European quality standards for pressure equipment. The PN40 rating indicates a nominal pressure capacity of 40 bar at 120°C, while the PN6 variant offers cost-effective solutions for lower-pressure applications. Both configurations maintain dimensional accuracy within ISO tolerance grades, ensuring seamless compatibility with global piping systems.

MARKING AND PACKING

Each DN800 flange undergoes comprehensive protective packaging beginning with VCI (Vapor Corrosion Inhibitor) coating to prevent corrosion during transit. Individual heavy-duty plastic wrapping provides primary protection, while custom-cut foam inserts safeguard machined surfaces and bolt holes. Wooden crates with reinforced framing ensure structural integrity during international shipping, with proper weight distribution and lifting points clearly marked for safe handling.

Our shipping process incorporates specialized handling protocols for oversized components. Each flange receives permanent identification marking including material grade, heat number, and pressure rating for easy inventory management. We optimize container loading to maximize space utilization while ensuring proper weight distribution, with detailed shipping documentation including packing lists, weight certificates, and handling instructions accompanying every shipment.

INSPECTION

Every flange undergoes rigorous testing protocols beginning with ultrasonic examination to detect internal flaws. Dimensional verification using laser measurement systems ensures compliance with EN1092-1 tolerances, while hydrostatic testing at 1.5 times rated pressure validates pressure containment capability. Material certification includes full chemical analysis and mechanical property testing with complete traceability from raw material to finished product.

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

COOPERATION CASE

A project in Turkey, flanges are used in natural gas pipelines. All those flanges are approved by TUV.

FLANGE DATA SHEET

1. Flange dimensions and tolerances shall be according to ASME B16.5.

2. Flanges shall be produced by forging.

3. Materials shall be according to ASTM A105, ASTM A694 F65 and ASTM A694 F70 standards.

4. ASTM A694 F65 and ASTM A694 F70 flanges shall be quenched and tempered.

5. Material test certificates and heat treatment reports shall be made available for TPI inspections.

6. WN flanges shall be with bevel ends acc. to ASME B16.25.

7. Materials chemical and mechanical test values(impact, yield,tensile etc.)shall be according to related standards.

8. All surfaces shall be machined and varnished with a transparent oil to prevent rusting.

9. Marking shall include the following information,

• Diameter (exp. 6”)

• Pressure class (exp. 150 LB)

• Material Grade (exp. ASTM A 105)

• Wall thickness (exp. 4,78 mm)

• Heat No (exp. 138413)

• Production standard (ASME B16.5)

10. Materials shall be free from any surface defects and cracks. Welding repairs are strictly forbidden.

11. All flanges shall be raised face (RF) with sealing surface. Sealing surface shall be Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. to ASME B46.1.

12. Materials shall be packed to prevent damages to machining, and sealing surfaces.

13. All dimensions shall be in positive (+) tolerances. Minus tolerances are strictly forbidden.

14. Flange bevellings shall be made acc. to ASME B16.25.

15. Manufacturing process will be checked at any time by TPI.

16. TPI may take samples from any material for chemical/mechanical test sample.

17. Incoming inspection report shall be reviewed by TPI.

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| S.O.R.F |

12 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

48 |

| S.O.R.F |

8 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

2 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

4 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

16 |

TANK FLANGES |

8 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

24 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

16 |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

10 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

PSB1 |

2 |

| Flange, Weld Neck |

6 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

4 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

18 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

Our quality assurance program encompasses statistical process control throughout manufacturing, with batch testing for consistency verification. Final inspection includes visual examination for surface defects, dimensional accuracy confirmation, and marking verification. All quality records are maintained for minimum 10 years, ensuring complete traceability and compliance with international quality standards.

FAQ

1. What are the different types of stainless steel pipe fittings?

Answer: Stainless steel pipe fittings include butt welding pipe fittings, socket welding pipe fittings, threaded pipe fittings, flanges, valves and other types.

2. What is the difference between stainless steel 304 and 316 stainless steel pipe fittings?

A: 304 stainless steel is suitable for most applications and has excellent corrosion resistance. 316 stainless steel, on the other hand, has better corrosion resistance in highly corrosive environments and is better suited for marine and chemical applications.

3. What are the benefits of using forged butt welded pipe fittings?

A: Forged butt weld fittings provide enhanced strength, reliability, and leak-free connections. They offer excellent impact resistance and are preferred for high pressure and high temperature applications.

4. What is a butt welding flange?

Answer: A butt welding flange is a pipe flange that has a long tapered hub and is welded to the pipe. It provides a smooth transition from pipe to flange with excellent strength and integrity.

5. Which stainless steel grade is commonly used for pipe fittings?

A: Stainless steel grades 304, 316, 304L, 316L and 317 are commonly used in pipe fittings due to their excellent corrosion resistance, durability and versatility.

6. Can stainless steel pipe fittings be used in high temperature applications?

Answer: Yes, stainless steel fittings are suitable for high temperature applications. However, the grade of stainless steel used should be carefully selected based on the specific temperature requirements of the application.

7. Are stainless steel pipe fittings suitable for the food and beverage industry?

Answer: Yes, stainless steel pipe fittings are widely used in the food and beverage industry because of their hygiene, corrosion resistance, and easy maintenance.

8. What is the difference between socket welding fittings and butt welding fittings?

Answer: Socket welded pipe fittings insert the pipe into the socket and then perform fillet welding to connect the pipe. Butt weld fittings, on the other hand, require the ends of the pipe to be beveled and then welded.

9. Can stainless steel pipe fittings be recycled?

A: Yes, stainless steel pipe fittings are highly recyclable. Stainless steel is a sustainable material that can be recycled and reused without losing its properties or quality.

10. What are the advantages of using stainless steel pipe fittings compared with other materials?

A: Stainless steel pipe fittings offer many advantages, such as excellent corrosion resistance, high strength, durability and hygienic properties. They are low maintenance, have a long lifespan and have a clean and beautiful appearance.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

Carbon Steel Forged ASME b16.36 wn orifice flan...

-

Screw BSP DIN PN 10/16 carbon steel A105 flange...

-

stainless steel forged lap joint loose flange c...

-

Customized LWN Flange Standard Carbon Steel Sta...

-

ASTM A182 F51 F53 BL ANSI B16.5 Stainless steel...

-

forged asme b16.36 wn orifice flange with Jack ...