SPECIFICATION

| Product Name | Plate flange |

| Size | 1/2"-250" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standard | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, etc. |

| Wall thickness | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

DIMENSION STANDARDS

PRODUCTS DETAIL SHOW

1. Face

Can be raised face(RF), full face(FF), Ring joint(RTJ) , Groove, Tongue, or customized.

2.Seal face

smooth face, waterlines, serrated finished

3.CNC fine finished.

Face finish: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. The range 3.2/6.3Ra is most common.

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

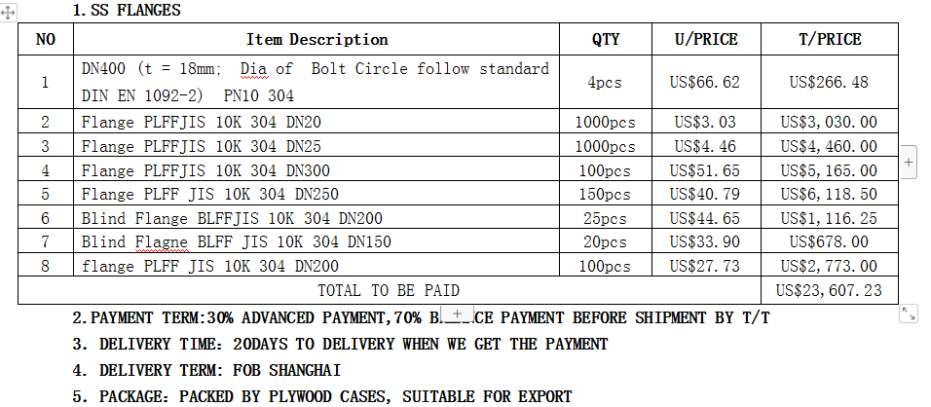

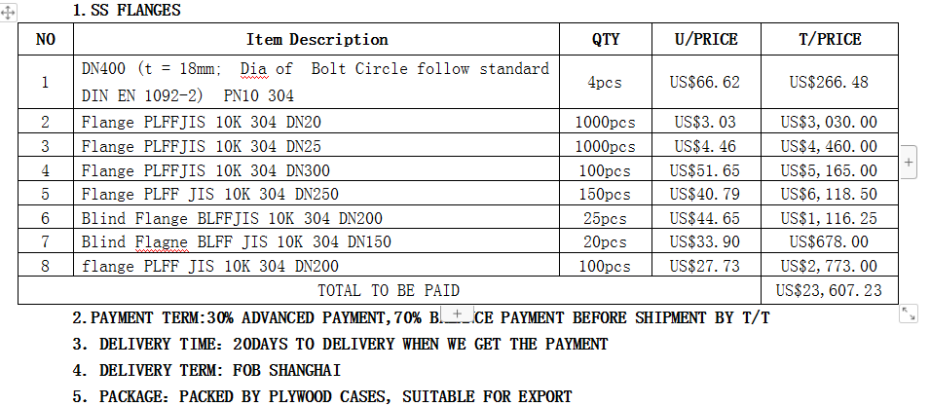

COOPERATION CASE

This order is for Vietnam stockist

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

FAQ

1. What is DIN ANSI 150LB PN16 Stainless Steel 304 316 316L Forged Plate Flange?

DIN ANSI 150LB PN16 Stainless Steel 304 316 316L Forged plate flange is a type of flange commonly used in industrial applications. It is made of stainless steel, specifically grades 304, 316 or 316L, which offers excellent corrosion resistance and high durability.

2. What are the benefits of using DIN ANSI 150LB PN16 stainless steel 304 316 316L forged plate flange?

These flanges offer several benefits, including the ability to withstand high pressure and high temperature environments. They are also highly resistant to corrosion, making them suitable for use in a variety of industries such as chemical, petrochemical, oil and gas, and food processing.

3. What is the significance of DIN and ANSI in flange specifications?

DIN and ANSI are two different standardization organizations that provide guidelines for the manufacture and dimensions of various industrial components. DIN refers to the German organization Deutsches Institut für Normung, while ANSI stands for the American National Standards Institute. The inclusion of both DIN and ANSI in the flange specification indicates that the product complies with the standards set by these organizations.

4. What do 150LB and PN16 in the flange description mean?

150LB refers to the pressure rating of the flange, indicating that the maximum pressure it can withstand is 150 pounds per square inch. PN16, on the other hand, stands for Nominal Pressure, which is the metric name for the pressure rating and specifies a maximum pressure of 16 bar.

5. Are DIN ANSI 150LB PN16 stainless steel 304 316 316L forged plate flanges suitable for corrosive environments?

Yes, due to the stainless steel construction of these flanges, they are ideal for use in corrosive environments. Stainless steel 304, 316 and 316L all offer excellent corrosion resistance, making them ideal for applications with frequent exposure to chemicals or moisture.

6. Can DIN ANSI 150LB PN16 Stainless Steel 304 316 316L Forged Plate Flange be used with different pipe materials?

Yes, these flanges can be used with a variety of pipe materials, including steel, stainless steel, plastic and copper. They are designed to provide safe, leak-free connections between different pipe components.

7. Are there different sizes for DIN ANSI 150LB PN16 stainless steel 304 316 316L forged plate flanges?

Yes, these flanges are available in a variety of sizes to suit different piping requirements. Common sizes include 1/2", 3/4", 1" and larger, allowing design and installation flexibility.

8. Can DIN ANSI 150LB PN16 Stainless Steel 304 316 316L forged plate flange be used in high temperature applications?

Yes, these flanges are designed to withstand high temperature environments. Stainless steel 304, 316 and 316L have good heat resistance, allowing flanges to maintain their structural integrity and performance even at high temperatures.

9. Is DIN ANSI 150LB PN16 Stainless Steel 304 316 316L Forged Plate Flange easy to install?

Yes, these flanges are designed for easy installation. They feature a simple bolt hole pattern for quick, direct connection to ductwork using standard bolts and nuts.

10. Where can I buy DIN ANSI 150LB PN16 stainless steel 304 316 316L forged plate flange?

These flanges can be purchased from a variety of industrial parts suppliers and dealers. It is recommended to consult your local hardware store, professional flange supplier or online marketplace to find a reliable source of these flanges.

Products detail show

1. Face

Can be raised face(RF), full face(FF), Ring joint(RTJ) , Groove, Tongue, or customized.

2.Seal face

smooth face, waterlines, serrated finished

3.CNC fine finished.

Face finish: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. The range 3.2/6.3Ra is most common.

Marking and packing

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

Inspection

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

Cooperation case

This order is for Vietnam stockist.

Production Process

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |