ERW Iron Pipe 6 Meter Welded Steel Pipe

We manufacture and supply premium quality ERW (Electric Resistance Welded) iron pipes through direct factory sales, eliminating intermediaries to provide cost-effective solutions for construction, infrastructure, and industrial applications. Our 6-meter standard length welded steel pipes are produced using advanced high-frequency welding technology, ensuring consistent quality, dimensional accuracy, and reliable performance. These black carbon steel pipes serve as fundamental components in structural frameworks, mechanical systems, and fluid transportation networks, offering optimal strength-to-weight ratios and economic efficiency.

Product parameters

| Product name | seamless pipes, ERW pipe, DSAW pipes. |

| Standard | ASME B36.10M, API 5L, ASTM A312, ASTM A213. ASTM A269, etc |

| Material | Carbon steel: A106 GR B, A53 GR B,ASTM A333 GR 6 etc. |

| Cr-Mo alloy: A335 P11, A335 P22, A335 P12, A335 P5, A335 P9, A335 P91,etc | |

| Pipeline steel: API 5L GR B, API 5L X42, API 5L X46, API 5L X56, API 5L X60, API 5L X65, API 5L X70,etc | |

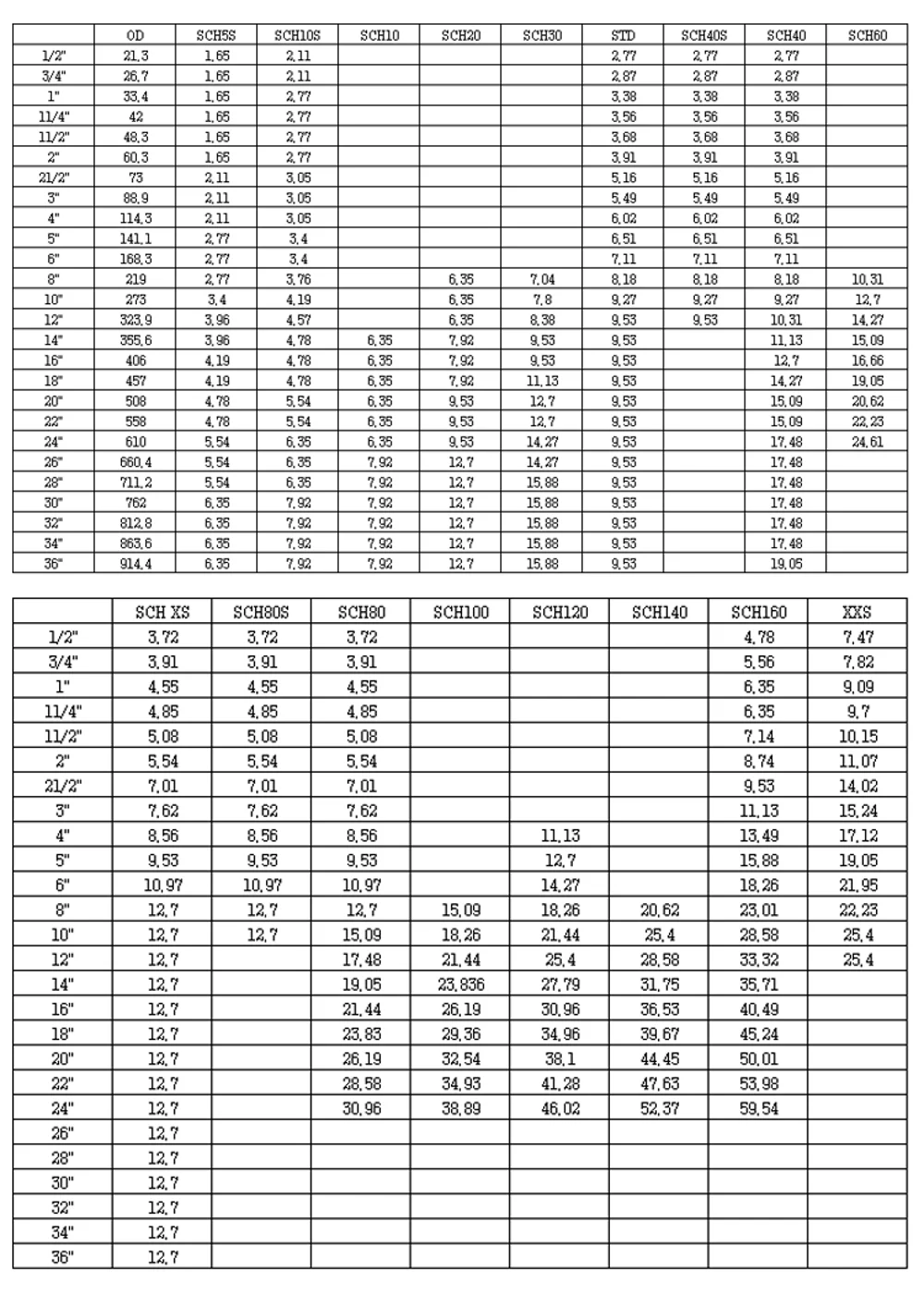

| OD | 3/8" -100" , customized |

| Wall thickness | SCH5S SCH10S, SCH10, SCH20,SCH30, SCH40S, STD, SCH40, SCH80S, SCH80,

XS, SCH60,SCH100, SCH120,SCH140,SCH160,XXS, customized , etc |

| Length | 5.8m, 6m, 11.8m, 12m, or as required |

| Surface | Black painting, 3PE coating, other special coating, etc |

| Application | Stainless steel pipe widely used in petroleum,chemical industry,electric power, boiler,high temperature resistant,

low temperature resistant, corrosion resistant., sour service, etc. |

| The size of the pipes can be made according to clients requirements. | |

| Contacts | If you have any questions, please feel free to contact me.we are sure your inquiry or requirements will get prompt attention. |

Material Processing

Hot Rolled Coils: ASTM A569, SAE 1006-1010 equivalents

Surface Quality: Commercial black finish with light mill scale

Decarburization Control: Maximum 0.05mm depth

Grain Structure: Fine-grained normalized structure

-

In-Process Testing

- Weld Seam Integrity: 100% ultrasonic testing at production line

- Dimensional Verification: Laser measurement systems every 30 minutes

- Visual Inspection: Continuous monitoring for surface defects

- Chemical Analysis: Spectrometer testing every heat/lot

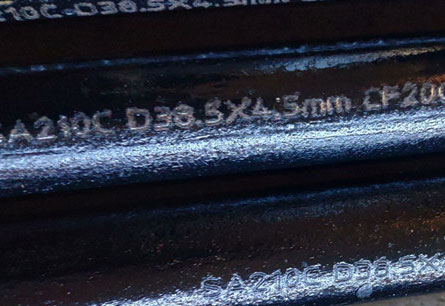

Marking

Printed or Curved marking on request. OEM is accepted.

Packaging & Shipping

Standard Packaging

Bundle Configuration: Hexagonal or rectangular bundling

Bundle Weight: 2-5 tons per bundle for handling efficiency

Protective Wrapping: Waterproof plastic wrapping with UV protection

Edge Protection: Plastic or metal end caps for thread protection

Identification: Color coding and waterproof tags

Shipping Specifications

Container Loading: 20ft container: 20-25 tons, 40ft container: 25-28 tons

Break Bulk Shipping: Up to 10,000 ton vessel capacity

Documentation: Complete shipping documents including weight certificates

Marking Requirements: Standard industry marking per specifications

Product description

Our factory-direct ERW iron pipes represent an optimal balance of quality, performance, and economic efficiency for a wide range of industrial and construction applications. Through advanced manufacturing technologies, rigorous quality control, and direct customer relationships, we deliver products that meet the highest standards of reliability and value.

The 6-meter standard length black carbon steel pipes provide versatile solutions for structural frameworks, mechanical systems, and fluid transportation networks, offering excellent mechanical properties, fabrication flexibility, and long-term durability. Our commitment to direct factory sales ensures competitive pricing without compromising quality or service.

FAQ

1. What is ASTM A312?

ASTM A312 is a specification for seamless, welded, and heavy cold worked austenitic stainless steel pipe for use in high temperature and generally corrosive environments.

2. What is black steel pipe?

Black steel pipe is a non-galvanized steel pipe with a dark iron oxide coating. The coating enhances corrosion resistance and gives the pipe its characteristic black appearance.

3. What are the benefits of using hot-rolled pipes?

Hot-rolled tubes offer several benefits, including improved formability, superior surface finish, improved dimensional accuracy and enhanced mechanical properties. They are typically used in applications that require strong, durable, and precision-engineered pipes.

4. Why are carbon steel pipes favored in various industries?

Carbon steel pipes are popular in various industries because of their strength, affordability, and versatility. It is widely used in oil and gas exploration, chemical processing, power generation, automobiles, construction and many other fields.

5. How is the manufacturing process of black steel pipe different from other pipes?

The manufacture of black steel pipes involves specific heating and cooling processes. The steel is heated to high temperatures, rolled into tubes, and then rapidly cooled to form a stable layer of iron oxide that gives the tube its black color.

6. What are the applications of ASTM A312 black steel pipe?

ASTM A312 black steel pipe is used in a variety of industries, including oil and gas, petrochemicals, water treatment, piping, HVAC systems, structural supports, and general manufacturing. It is commonly used to transport fluids and gases under high pressure and high temperature conditions.

7. Can black steel pipes be used outdoors?

Yes, black steel pipe is available for outdoor applications. The iron oxide coating provides excellent protection against corrosion, making it suitable for a wide range of environmental conditions. However, additional protective coatings may be required in extremely corrosive environments.

8. Are hot rolled tubes suitable for precision engineering applications?

Yes, hot rolled pipes are widely used in precision engineering applications. Its improved dimensional accuracy and superior surface finish make it ideal for manufacturing high-precision components, machinery and structures requiring tight tolerances.

9. What are the advantages of carbon steel pipes compared with other materials?

Carbon steel pipes offer several advantages, including high tensile strength, excellent wear resistance, good machinability and ease of welding. It is also cost-effective and available in a variety of sizes and specifications.

10. Is ASTM A312 black steel pipe suitable for high temperature applications?

Yes, ASTM A312 black steel pipe is specifically designed for high temperature applications. They have excellent heat resistance and are suitable for conveying steam, hot water and other high temperature fluids.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

AMS 5533 Nickel 200 201 Metal pipes ASTM B162 A...

-

Pipe Stainless Steel Aisi 304l Seamless Thickne...

-

manufacture ERW EN10210 S355 carbon steel pipe ...

-

Hot Dip Galvanized 6 Inch Sch 40 A179 Gr.B Roun...

-

Boiler Tube Carbon Steel DIN17175 St45 Seamless...

-

A249 stainless steel seamless pipe thickness 1....