Product parameters

| Product name | seamless pipes, ERW pipe, DSAW pipes. |

| Standard | ASME B36.10M, API 5L, ASTM A312, ASTM A213. ASTM A269, etc |

| Material | Carbon steel: A106 GR B, A53 GR B,ASTM A333 GR 6 etc. |

| Cr-Mo alloy: A335 P11, A335 P22, A335 P12, A335 P5, A335 P9, A335 P91,etc | |

| Pipeline steel: API 5L GR B, API 5L X42, API 5L X46, API 5L X56, API 5L X60, API 5L X65, API 5L X70,etc | |

| OD | 3/8" -100" , customized |

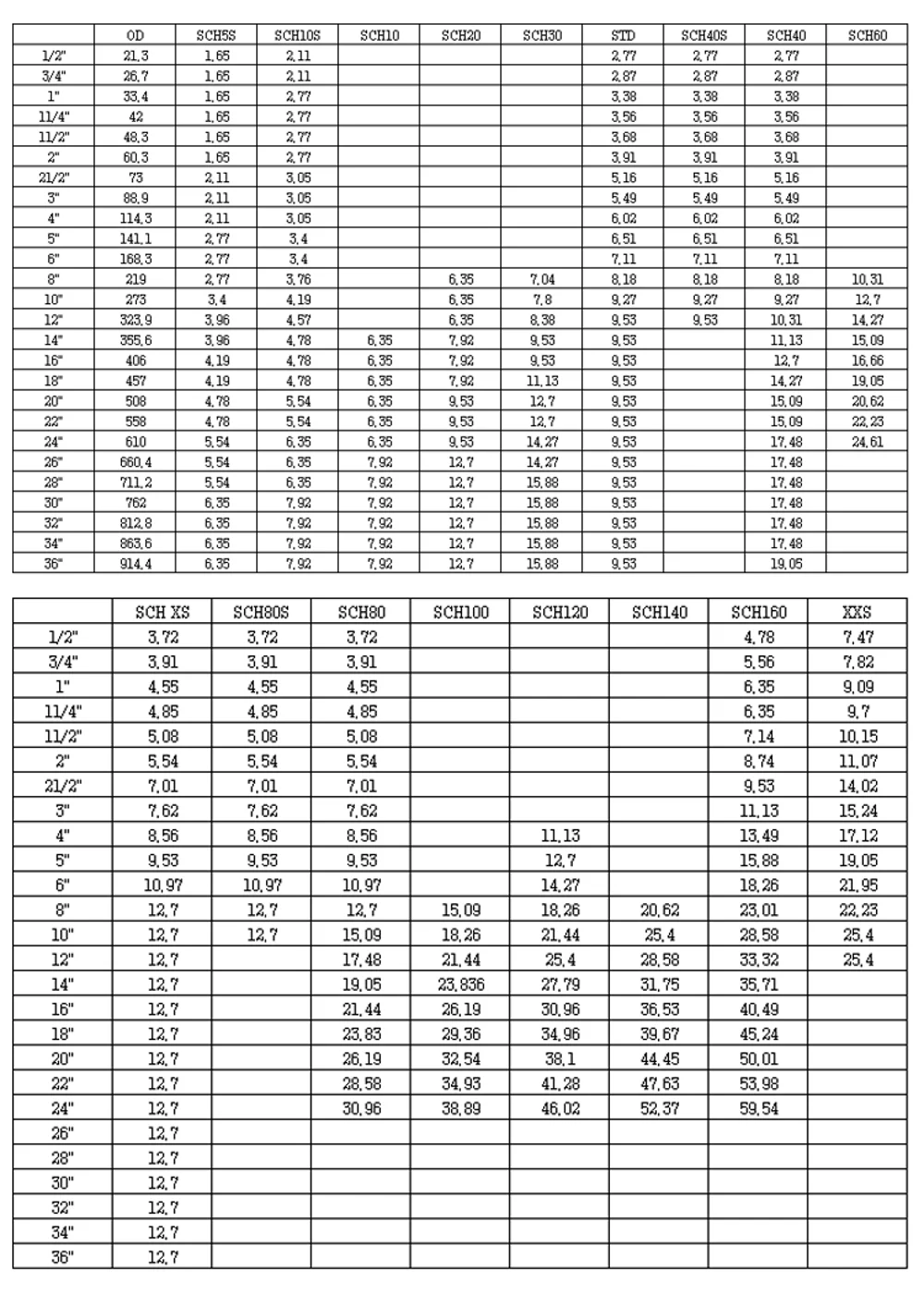

| Wall thickness | SCH5S SCH10S, SCH10, SCH20,SCH30, SCH40S, STD, SCH40, SCH80S, SCH80,

XS, SCH60,SCH100, SCH120,SCH140,SCH160,XXS, customized , etc |

| Length | 5.8m, 6m, 11.8m, 12m, or as required |

| Surface | Black painting, 3PE coating, other special coating, etc |

| Application | Stainless steel pipe widely used in petroleum,chemical industry,electric power, boiler,high temperature resistant,

low temperature resistant, corrosion resistant., sour service, etc. |

| The size of the pipes can be made according to clients requirements. | |

| Contacts | If you have any questions, please feel free to contact me.we are sure your inquiry or requirements will get prompt attention. |

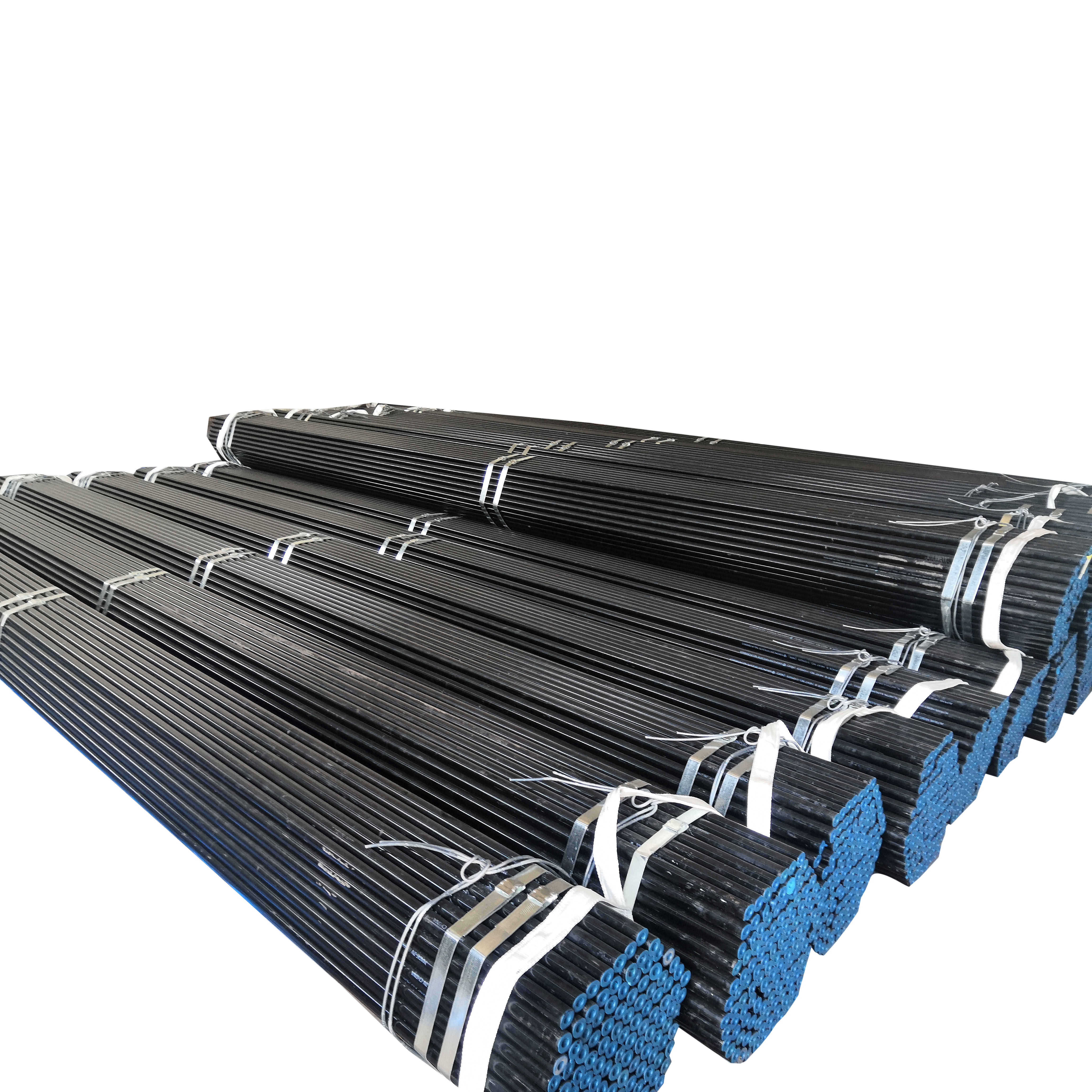

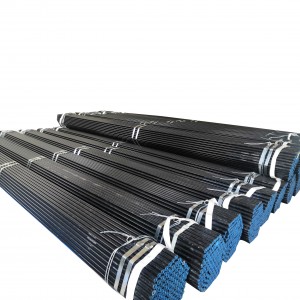

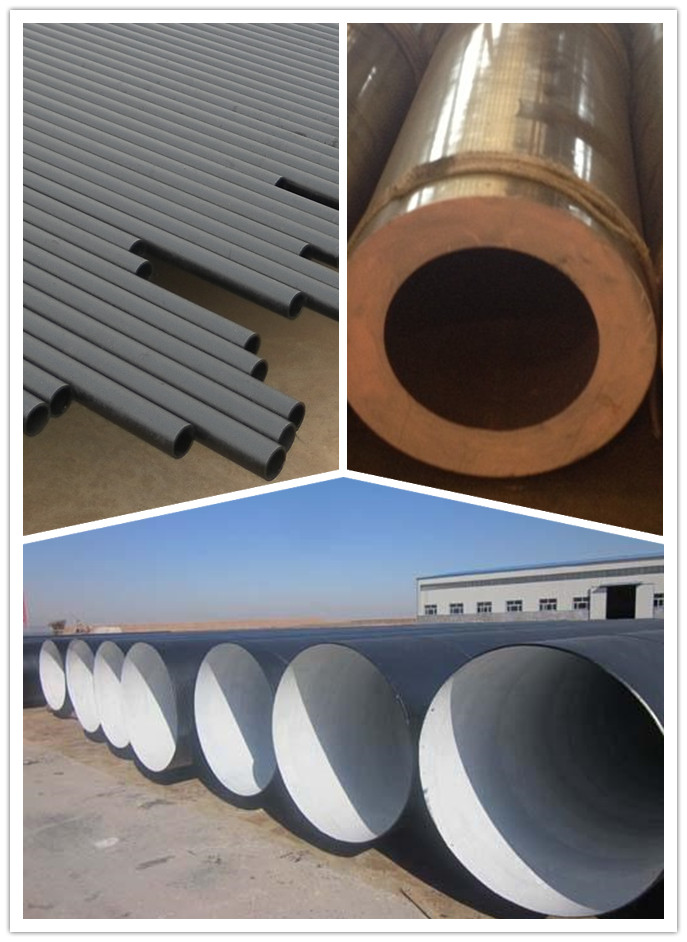

Detailed photos

1. Varnished, black painting, 3 LPE coating etc.

2. End can be bevel end or plain end

3. length can be on request, customized.

Inspection

1. PMI, UT ,RT, X-ray test.

2. Dimension test.

3. Supply MTC, inspection certificate, EN10204 3.1/3.2.

4. NACE certificate, sour service

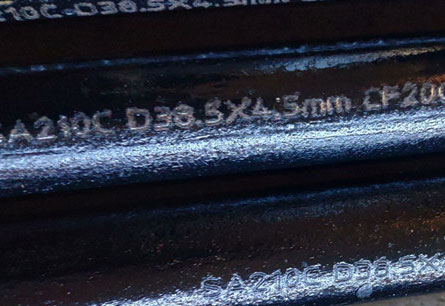

Marking

Printed or Curved marking on request. OEM is accepted.

Packaging & Shipping

1. End will be protected by plastic caps.

2. Smaller tubes are packed by plywood case.

3. Bigger pipes are packed by bundling.

4. All package, we will put packing list.

5. Shipping marks on our request

Product description

Carbon steel pipes are divided into hot rolled and cold rolled (drawn) steel pipes.

Hot rolled carbon steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipes.

Cold rolled (dial) carbon steel pipe in addition to general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking pipe, other steel pipe, also includes carbon thin-wall steel pipe, alloy thin-wall steel pipe, stainless thin-wall steel pipe, special-shaped steel pipe. The outer diameter of the hot-rolled seamless pipe is generally greater than 32mm, the wall thickness is 2.5-75mm, the outer diameter of the cold-rolled seamless steel pipe can be 6mm, the wall thickness can be 0.25mm, the outer diameter of the thin-walled pipe can be 5mm, the wall thickness is less than 0.25mm, and the size accuracy is higher than that of the hot-rolled seamless pipe.

General carbon steel pipe: is made of 10, 20, 30, 35, 45 and other high-quality carbon junction steel 16Mn, 5MnV and other low alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot rolled or cold rolled. Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid transport pipelines. 45, 40Cr and other medium carbon steel seamless pipe to manufacture mechanical parts, such as cars, tractor parts. Generally used carbon steel pipe to ensure strength and flattening test. Hot-rolled steel pipes are delivered in hot-rolled or heat-treated condition; Delivered cold rolled in heat-treated condition.

FAQ

1. What is ASTM A312?

ASTM A312 is a specification for seamless, welded, and heavy cold worked austenitic stainless steel pipe for use in high temperature and generally corrosive environments.

2. What is black steel pipe?

Black steel pipe is a non-galvanized steel pipe with a dark iron oxide coating. The coating enhances corrosion resistance and gives the pipe its characteristic black appearance.

3. What are the benefits of using hot-rolled pipes?

Hot-rolled tubes offer several benefits, including improved formability, superior surface finish, improved dimensional accuracy and enhanced mechanical properties. They are typically used in applications that require strong, durable, and precision-engineered pipes.

4. Why are carbon steel pipes favored in various industries?

Carbon steel pipes are popular in various industries because of their strength, affordability, and versatility. It is widely used in oil and gas exploration, chemical processing, power generation, automobiles, construction and many other fields.

5. How is the manufacturing process of black steel pipe different from other pipes?

The manufacture of black steel pipes involves specific heating and cooling processes. The steel is heated to high temperatures, rolled into tubes, and then rapidly cooled to form a stable layer of iron oxide that gives the tube its black color.

6. What are the applications of ASTM A312 black steel pipe?

ASTM A312 black steel pipe is used in a variety of industries, including oil and gas, petrochemicals, water treatment, piping, HVAC systems, structural supports, and general manufacturing. It is commonly used to transport fluids and gases under high pressure and high temperature conditions.

7. Can black steel pipes be used outdoors?

Yes, black steel pipe is available for outdoor applications. The iron oxide coating provides excellent protection against corrosion, making it suitable for a wide range of environmental conditions. However, additional protective coatings may be required in extremely corrosive environments.

8. Are hot rolled tubes suitable for precision engineering applications?

Yes, hot rolled pipes are widely used in precision engineering applications. Its improved dimensional accuracy and superior surface finish make it ideal for manufacturing high-precision components, machinery and structures requiring tight tolerances.

9. What are the advantages of carbon steel pipes compared with other materials?

Carbon steel pipes offer several advantages, including high tensile strength, excellent wear resistance, good machinability and ease of welding. It is also cost-effective and available in a variety of sizes and specifications.

10. Is ASTM A312 black steel pipe suitable for high temperature applications?

Yes, ASTM A312 black steel pipe is specifically designed for high temperature applications. They have excellent heat resistance and are suitable for conveying steam, hot water and other high temperature fluids.