DN25 25A sch160 90 degree elbow pipe fitting

The Factory DN25 SCH160 90-Degree Elbow is a precision-engineered, high-pressure pipe fitting designed for critical applications where reliability and structural integrity are non-negotiable. Manufactured from seamless ASTM A234 WPB carbon steel in full compliance with ASME B16.9 standards, this 1.5D Long Radius elbow is the optimal solution for integrating into Schedule 160 high-pressure piping systems. Its seamless construction ensures superior pressure containment, exceptional fatigue resistance, and enhanced safety compared to welded fittings, making it the preferred component for demanding services in petrochemical, power generation, and oil & gas infrastructure.

This elbow is engineered to facilitate a smooth 90-degree directional change in high-pressure fluid flow, minimizing turbulence and systemic pressure drop thanks to its optimized 1.5D bend radius. The specification of ASTM A234 WPB material guarantees excellent weldability and robust mechanical properties, enabling the creation of strong, leak-free butt-weld joints that become an integral part of the pipeline. Designed for longevity and unwavering performance in harsh operating environments, this fitting is a fundamental building block for engineers and contractors worldwide who are committed to constructing durable, high-integrity piping networks.

PRODUCT PARAMETERS

| Product Name | Pipe elbow |

| Size | 1/2"-36" seamless elbow(SMLS elbow), 26"-110" welded with seam. Biggest outside diameter can be 4000mm |

| Standard | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Degree | 30° 45° 60° 90° 180°,etc |

| Radius | LR/long radius/R=1.5D,SR/Short radius/R=1D |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 , 12crmov, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

PIPE FITTINGS

Butt welded pipe fittings includes steel pipe elbow, steel pipe tee, steel pipe reduer, steel pipe cap. All those butt welding pipe fittings, we can supply together, we have more 20 years production experiences.

If you are also interested other fittings, please click followed LINK to check details.

PIPE TEE PIPE REDUCER PIPE CAP PIPE BEND FORGED FITTINGS

Material & Manufacturing:

This elbow is manufactured from ASTM A234 WPB seamless pipe, a wrought carbon steel material specified for moderate temperature service, offering an optimal balance of strength and toughness. The production employs a seamless hot pushing or induction heating and bending process. This method ensures the elbow body is free from any longitudinal weld seam, thereby eliminating a potential line of weakness. Post-forming, each fitting undergoes normalizing heat treatment to refine the grain structure, relieve forming stresses, and restore the material's optimal mechanical properties.

Precision Dimensional Control:

Manufactured with strict adherence to ASME B16.9 dimensional tolerances.

- Outside Diameter: 33.4 mm (±0.8mm tolerance).

- Wall Thickness: Corresponds to SCH160 minimum wall thickness (approx. 6.55mm). Production ensures uniform wall thickness, with thinning at the extrados carefully controlled within ASME allowable limits.

- Center-to-End Dimension: Precisely maintained at 38mm (±1.5mm).

- Out-of-Roundness: Tightly controlled at the pipe ends to ensure perfect alignment and fit-up with mating pipe.

- Weld Bevel: Both ends feature a machined 37.5° weld bevel with a 1.6mm (±0.8mm) land, providing a clean, consistent preparation for high-integrity welding.

Surface & Marking:

The internal and external surfaces are smooth, promoting an unobstructed flow path to reduce pressure loss. As standard, the surface is supplied with a black mill scale finish; sandblasting to Sa2.5 cleanliness is available upon request. Each elbow is permanently marked in accordance with ASTM A960, including: Material Grade (A234 WPB), Size (1" SCH160), Manufacturer's Identification or Brand, and a traceable Heat Number.

Raw Material Verification:

Every batch of ASTM A234 WPB seamless pipe used in production is accompanied by a Mill Test Certificate compliant with ASTM A960. Upon receipt, we perform spectrochemical analysis to verify compliance with the standard's chemical composition requirements for elements like Carbon, Manganese, Silicon, Phosphorus, and Sulfur. Samples from the same heat lot undergo mechanical property testing to confirm tensile strength, yield strength, and elongation meet A234 WPB specifications (e.g., min. tensile strength 415 MPa, min. yield strength 240 MPa).

Dimensional & Geometrical Inspection:

Each finished elbow undergoes 100% dimensional inspection.

- Digital Calipers and Ultrasonic Thickness Gauges are used to precisely measure the outside diameter and wall thickness at multiple points, with particular attention to the extrados (outer bend) where thinning may occur.

- Protractors and Center-to-End Gauges verify the 90-degree bend angle and center-to-end distance.

- Out-of-Roundness Gauges check for port ellipticity.

- Weld Bevel Gauges ensure the bevel angle and land dimensions conform to welding specifications.

Surface & Non-Destructive Testing (NDT):

- Visual Inspection: A thorough examination of internal and external surfaces for defects such as cracks, seams, or laminations.

- Magnetic Particle Testing (MT) or Liquid Penetrant Testing (PT): The entire external surface, including the beveled ends, is examined using these methods to detect surface and near-surface flaws. This testing is performed by personnel certified to ASNT SNT-TC-1A Level II.

- Ultrasonic Thickness (UT) Scanning: Focused scanning is conducted on the extrados and other potential thinning areas to ensure the wall thickness meets or exceeds the design minimum.

Process Control & Verification:

- Heat Treatment Monitoring: The temperature and time curves for the normalizing heat treatment are automatically recorded and archived, ensuring process consistency and traceability.

- Hydrostatic Testing (Optional): Upon client request, individual elbows can be subjected to hydrostatic pressure testing, typically at 1.5 times the pressure rating for the applicable temperature, to validate pressure-containing integrity and leak-tightness.

Final Inspection & Documentation:

All inspection data is recorded in an Inspection and Test Plan (ITP). Products passing all checks receive a Final Inspection Release Certificate. The complete documentation package available includes: Mill Test Certificate (MTC 3.1), Dimensional Inspection Report, Non-Destructive Test Reports (if applicable), Heat Treatment Records, and Third-Party Inspection Reports (when requested by the client).

ELBOW SURFACE

Sand Blast

After hot forming, we arrange sand blast to make the surface to be clean and smooth.

After Sand blast, to avoid get rust, should do black painting or anti-rust oil, Hot dip galvanized (HDG) , epoxy, 3PE, vanished surface, etc. That is depend on customer's request.

HEAT TREATMENT

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO.

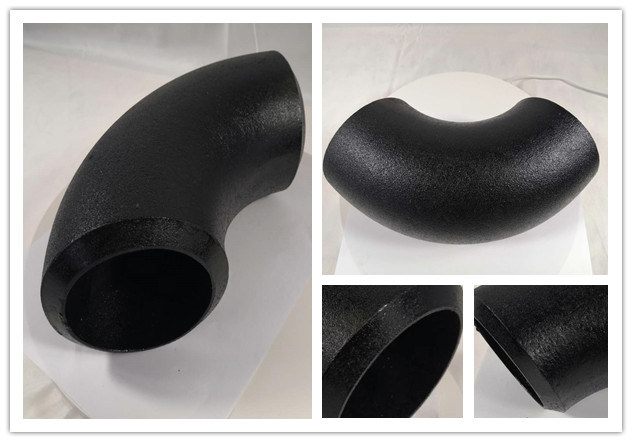

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Sand blast first, then Perfect painting work. Also can be varnished.

3. Without lamination and cracks.

4. Without any weld repairs.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. MT, UT,X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate

PACKAGING& SHIPPING

Upon final approval, each DN25 SCH160 elbow is immediately coated with anti-corrosive oil on the beveled ends and machined surfaces. It is then individually sealed in a Vapor Corrosion Inhibitor (VCI) plastic bag, providing robust protection against corrosion during transit and storage. For bulk orders, individually packed elbows are neatly arranged in sturdy export-grade wooden crates or reinforced cartons, with internal foam or cardboard dividers to prevent contact damage. Crates are externally reinforced with steel straps and clearly marked with handling symbols like "Fragile" and "Keep Dry."

Versatile Industrial Applications:

This high-pressure, heavy-wall elbow is the ideal choice for critical applications across key industries:

- Oil & Gas: High-pressure lines in wellhead assemblies, metering skids, compressor station piping, and high-pressure hydroprocessing units in refineries.

- Power Generation: High-pressure feedwater lines, main steam bypass systems, and connections for high-pressure heaters in power plants.

- Chemical & Petrochemical: Feed and discharge lines for high-pressure reactors, connections for high-pressure heat exchangers, and piping in high-pressure synthesis processes (e.g., urea).

- Industrial Machinery: Inlet and outlet piping for high-pressure pumps, hydraulic system lines, and applications subject to severe pressure cycling or pulsation.

Our Competitive Advantages:

- Specialization in High-Pressure Fittings: We possess dedicated expertise in manufacturing SCH160 and higher-class fittings, with material selection and process controls specifically optimized for high-pressure service.

- Seamless Integrity Guarantee: Our commitment to seamless manufacturing technology eliminates the risks associated with weld seams, delivering the highest level of safety and reliability for our clients.

- Rigorous Quality Management: A multi-stage inspection protocol, with stringent checks at each production step—especially critical NDT for high-pressure components—ensures a zero-defect philosophy for outgoing products.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.