Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Factory DN25 DN40 DN80 DN100 DN150 DN600 Weld Neck Forging Flanges, Customers' benefit and gratification are normally our biggest intention. Remember to get in touch with us. Give us a probability, provide you with a surprise.

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for China Forging Centrifugal Pump Flanges, Weld Neck Flanges, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality solutions and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

SPECIFICATION

| Product Name | Lap joint/Loose flange |

| Size | 1/2"-24" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5,EN1092-1, JIS B2220 etc. |

| Stub end | MSS SP 43, ASME B16.9 |

| Material | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo and etc. |

| Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 etc. | |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc. | |

| Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry;gas exhaust;power plant;ship building;water treatment,etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

DIMENSION STANDARDS

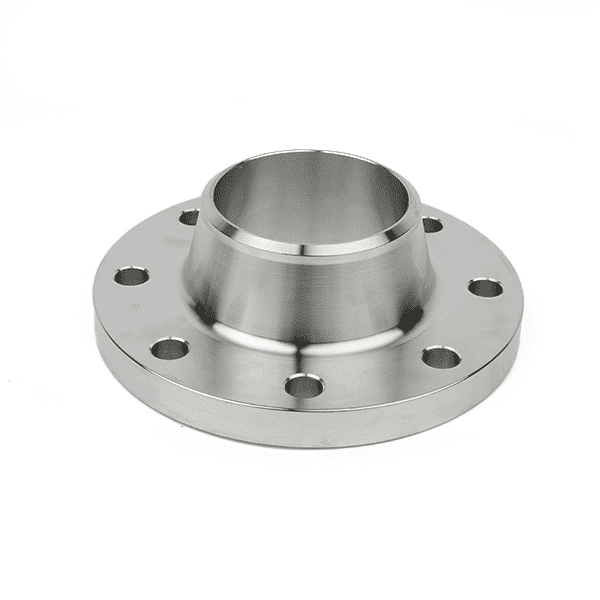

PRODUCTS DETAIL SHOW

1. Face

Can be raised face(RF), full face(FF), Ring joint(RTJ) , Groove, Tongue, or customized.

2.Bevel end as per ANSI B16.25

3.CNC fine finished.

Face finish: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. The range 3.2/6.3Ra is most common.

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

COOPERATION CASE

A project in Turkey, flanges are used in natural gas pipelines. All those flanges are approved by TUV.

FLANGE DATA SHEET

1. Flange dimensions and tolerances shall be according to ASME B16.5.

2. Flanges shall be produced by forging.

3. Materials shall be according to ASTM A105, ASTM A694 F65 and ASTM A694 F70 standards.

4. ASTM A694 F65 and ASTM A694 F70 flanges shall be quenched and tempered.

5. Material test certificates and heat treatment reports shall be made available for TPI inspections.

6. WN flanges shall be with bevel ends acc. to ASME B16.25.

7. Materials chemical and mechanical test values(impact, yield,tensile etc.)shall be according to related standards.

8. All surfaces shall be machined and varnished with a transparent oil to prevent rusting.

9. Marking shall include the following information,

• Diameter (exp. 6”)

• Pressure class (exp. 150 LB)

• Material Grade (exp. ASTM A 105)

• Wall thickness (exp. 4,78 mm)

• Heat No (exp. 138413)

• Production standard (ASME B16.5)

10. Materials shall be free from any surface defects and cracks. Welding repairs are strictly forbidden.

11. All flanges shall be raised face (RF) with sealing surface. Sealing surface shall be Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. to ASME B46.1.

12. Materials shall be packed to prevent damages to machining, and sealing surfaces.

13. All dimensions shall be in positive (+) tolerances. Minus tolerances are strictly forbidden.

14. Flange bevellings shall be made acc. to ASME B16.25.

15. Manufacturing process will be checked at any time by TPI.

16. TPI may take samples from any material for chemical/mechanical test sample.

17. Incoming inspection report shall be reviewed by TPI.

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| S.O.R.F |

12 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

48 |

| S.O.R.F |

8 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

2 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

4 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

16 |

TANK FLANGES |

8 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

24 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

16 |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

10 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

PSB1 |

2 |

| Flange, Weld Neck |

6 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

4 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

18 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Factory Outlets China Malleable DN25 DN40 DN80 DN100 DN150 DN600 Metal Decorative Pipe Fitting 304 Stainless Steel Weld Neck Forging Centrifugal Pump Flanges, Customers' benefit and gratification are normally our biggest intention. Remember to get in touch with us. Give us a probability, provide you with a surprise.

Factory Outlets China Forging Centrifugal Pump Flanges, Weld Neck Flanges, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality solutions and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

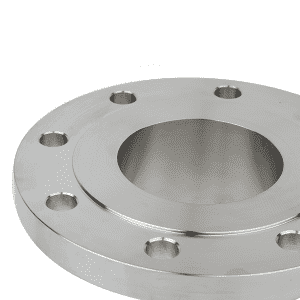

PRODUCTS DETAIL SHOW

1. Face

Can be raised face(RF), full face(FF), Ring joint(RTJ) , Groove, Tongue, or customized.

2.Bevel end as per ANSI B16.25

3.CNC fine finished.

Face finish: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. The range 3.2/6.3Ra is most common.

MARKING AND PACKING

• Each layer use plastic film to protect the surface

• For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

• Shipping mark can make on request

• Markings on products can be carved or printed. OEM is accepted.

INSPECTION

• UT test

• PT test

• MT test

• Dimension test

Before delivery, our QC team will arrange NDT test and dimension inspection.Also accept TPI(third party inspection).

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

COOPERATION CASE

A project in Turkey, flanges are used in natural gas pipelines. All those flanges are approved by TUV.

FLANGE DATA SHEET

1. Flange dimensions and tolerances shall be according to ASME B16.5.

2. Flanges shall be produced by forging.

3. Materials shall be according to ASTM A105, ASTM A694 F65 and ASTM A694 F70 standards.

4. ASTM A694 F65 and ASTM A694 F70 flanges shall be quenched and tempered.

5. Material test certificates and heat treatment reports shall be made available for TPI inspections.

6. WN flanges shall be with bevel ends acc. to ASME B16.25.

7. Materials chemical and mechanical test values(impact, yield,tensile etc.)shall be according to related standards.

8. All surfaces shall be machined and varnished with a transparent oil to prevent rusting.

9. Marking shall include the following information,

• Diameter (exp. 6”)

• Pressure class (exp. 150 LB)

• Material Grade (exp. ASTM A 105)

• Wall thickness (exp. 4,78 mm)

• Heat No (exp. 138413)

• Production standard (ASME B16.5)

10. Materials shall be free from any surface defects and cracks. Welding repairs are strictly forbidden.

11. All flanges shall be raised face (RF) with sealing surface. Sealing surface shall be Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. to ASME B46.1.

12. Materials shall be packed to prevent damages to machining, and sealing surfaces.

13. All dimensions shall be in positive (+) tolerances. Minus tolerances are strictly forbidden.

14. Flange bevellings shall be made acc. to ASME B16.25.

15. Manufacturing process will be checked at any time by TPI.

16. TPI may take samples from any material for chemical/mechanical test sample.

17. Incoming inspection report shall be reviewed by TPI.

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| S.O.R.F |

12 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

48 |

| S.O.R.F |

8 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

32 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

2 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

4 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

16 |

TANK FLANGES |

8 |

| S.O.R.F |

3 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

24 |

| S.O.R.F |

20 |

150LB |

20 |

A105 |

- |

TANK FLANGES |

6 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

5.54 |

TANK FLANGES |

8 |

| Flange, Weld Neck |

24 |

150LB |

20 |

A105 |

14 |

TANK FLANGES |

16 |

|

Item |

Size (Inch) |

Pressure Class |

CS |

Material |

W.T. (mm) |

Location |

Qty. |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

2 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

6 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

4 |

| Flange, Weld Neck |

20 |

400LB |

62 |

ASTM A694 F70 |

7.14 |

PSM1 |

10 |

| Flange, Weld Neck |

12 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

4 |

| Flange, Weld Neck |

24 |

400LB |

62 |

ASTM A694 F70 |

7.92 |

PSM1 |

25 |

| Flange, Weld Neck |

4 |

400LB |

62 |

ASTM A694 F70 |

4.78 |

PSM1 |

16 |

| Flange, Weld Neck |

10 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

PSB1 |

2 |

| Flange, Weld Neck |

6 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

4 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

4 |

| Flange, Weld Neck |

18 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |

| Flange, Weld Neck |

8 |

300LB |

51 |

ASTM A694 F65 |

4.78 |

RABIGH |

2 |