Forged ASME B16.36 WN Orifice Flange with Jack Screw

The Forged ASME B16.36 Weld Neck Orifice Flange with Jack Screw represents a precision-engineered flow measurement component designed for critical process applications across demanding industrial sectors. This specialized flange integrates advanced forging technology with practical design features to ensure accurate, reliable, and safe operation in high-pressure and high-temperature systems. Manufactured in strict compliance with ASME B16.36 and B16.5 standards, it serves as an essential component in fluid measurement and control systems.

SPECIFICATION

|

Product Name

|

weld neck Orifice flange

|

|||

|

SIZE

|

1" up ro 24"

|

|||

|

Pressure

|

150#-2500#

|

|||

|

Standard

|

ANSI B16.36

|

|||

|

Wall thickness

|

SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc.

|

|||

|

Material

|

Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S,

A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. Carbon steel: A105, A350LF2, Q235, St37, St45.8, A42CP, E24 , A515 Gr60, A515 Gr 70 |

|||

|

Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 ,

UNS32760, 1.4462,1.4410,1.4501 and etc. Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. |

||||

|

Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,

C22, C-276, Monel400, Alloy20 etc. Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 etc. |

||||

|

Application

|

Petrochemical industry;avation and aerospace industry;pharmaceutical industry;

gas exhaust;power plant;ship building;water treatment,etc. |

|||

|

Advantages

|

ready stock,faster delivery time;available in all sizes,customized;high quality

|

|||

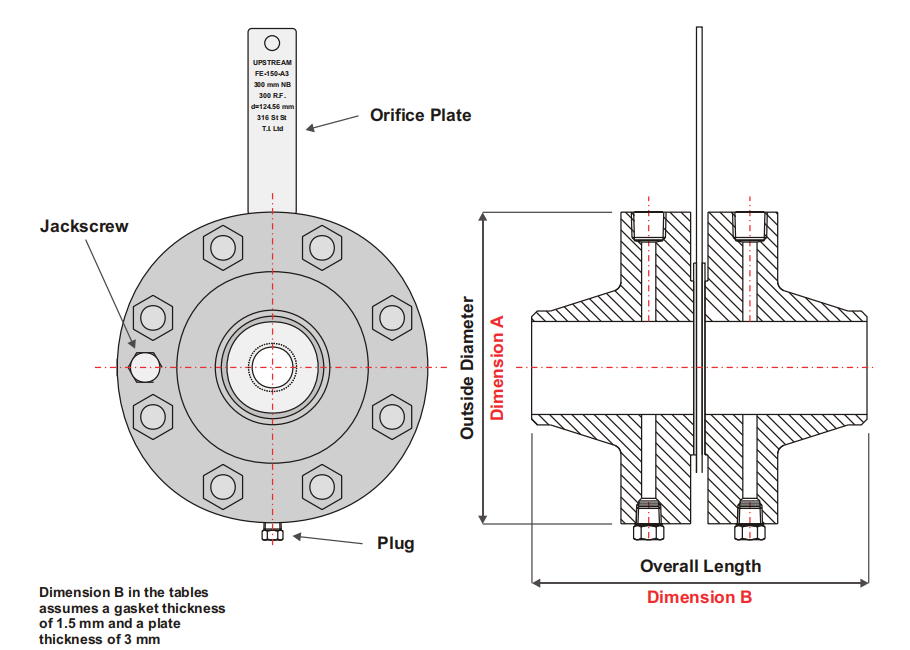

DIMENSION STANDARDS

PRODUCTS DETAIL

1.Weld Neck Configuration

Extended tapered hub design for optimal stress distribution

Smooth transition from flange to pipe minimizes turbulence

Enhanced structural integrity for high-pressure applications

2.Integrated Jack Screw System

Minimum of two jack screws (90° apart, additional screws available for larger sizes)

Standard ½"-13 UNC threaded holes (other thread specifications available)

Facilitates safe orifice plate installation and removal without system disassembly

Prevents flange face damage during maintenance operations

3.Orifice Bore Precision

Machined to strict dimensional tolerances (±0.001" standard)

Smooth bore surface finish (Ra ≤ 63 µin)

Concentricity maintained within 0.005" TIR

4.Raised Face Design

Standard 1/16" raised face (RF) with serrated finish (125-250 AARH)

Alternative face types available (FF, RTJ, T&G)

Optimal gasket compression and sealing performance

MARKING AND PACKING

Protective Packaging

Individual plastic wrapping with VCI protection

Wooden crates with proper bracing for international shipping

Protective caps for jack screw threads

Clear identification and marking per ASME requirements

Shipping Documentation

Commercial invoice and packing list

Certificate of origin

Material certification package

Mill test reports and inspection certificates

INSPECTION

1.Material Verification

Spectrochemical analysis

Mechanical property testing (tensile, yield, elongation)

Charpy impact testing for low-temperature applications

2.Non-Destructive Examination

Liquid Penetrant Testing (PT) per ASME Sec V Article 6

Magnetic Particle Testing (MT) for ferritic materials

Ultrasonic Testing (UT) for internal defects

Hardness testing across critical sections

3.Dimensional Verification

100% dimensional inspection per ASME B16.36

Bore diameter and concentricity verification

Bolt hole circle and drilling pattern confirmation

Thickness and face flatness measurements

COOPERATION CASE

The Forged ASME B16.36 WN Orifice Flange with Jack Screw represents the culmination of advanced metallurgical engineering, precision manufacturing, and practical design innovation. Each component is manufactured with uncompromising attention to detail, ensuring reliable performance in the most demanding process conditions. Our commitment to quality, combined with decades of industry experience, makes these flanges the preferred choice for engineers and operators worldwide who demand accuracy, reliability, and safety in their flow measurement systems.

PRODUCTION PROCESS

| 1. Choose Genuine raw material | 2. Cut raw material | 3. Pre-heating |

| 4. Forging | 5. Heat treatment | 6. Rough Machining |

| 7. Drilling | 8. Fine maching | 9. Marking |

| 10. Inspection | 11. Packing | 12. Delivery |

Introducing our high quality butt welded orifice flanges, designed to meet the demanding requirements of a variety of industrial applications. Our orifice flanges are designed to provide reliable, efficient solutions for measuring the flow of liquids, gases and steam in pipes.

Our butt weld orifice flanges are made from high quality materials and offer exceptional durability and corrosion resistance, making them suitable for use in harsh and corrosive environments. The precision machining of the flange ensures a perfect fit and tight seal, minimizing the risk of leakage and ensuring long-term performance.

The welded neck design of our orifice flanges creates a strong and secure connection to the piping system for enhanced stability and support. This design also helps reduce stress concentrations at flange connections, thereby improving the overall integrity of the system.

Our orifice flanges are available in a variety of sizes and pressure ratings to meet different application requirements. Whether used in the oil and gas, petrochemical, chemical processing or power generation industries, our weld neck orifice flanges provide consistent and accurate flow measurement.

In addition to their sturdy construction, our orifice flanges are easy to install and maintain, saving our customers valuable time and resources. The smooth surface finish and precise dimensions further enhance ease of handling and assembly.

We understand the critical role orifice plate flanges play in ensuring the efficiency and safety of industrial processes. That's why we're committed to providing products that meet the highest quality standards and performance specifications.

With our butt weld orifice flanges, you can trust that your flow measurement applications will benefit from reliable, long-lasting and accurate performance. Experience the difference with our top-of-the-line butt weld orifice plate flanges and increase the efficiency of your operations.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.