Incoloy Alloy 800 Seamless Pipe & Tube

We supply premium Incoloy Alloy 800 seamless pipes and tubes (UNS N08800) manufactured in strict compliance with ASTM B407 and ASME SB163 standards.

These high-performance nickel-iron-chromium alloy components are engineered for exceptional strength and corrosion resistance in elevated temperature applications.

Product parameters

| Product name | seamless pipes, ERW pipe,EFW pipe, DSAW pipes. |

| Standard | ASME B36.10M, API 5L, ASTM A312, ASTM A213. ASTM A269, etc |

| Material | stainless steel: 304, 316, 317, 904L, 321, 304h, 316ti, 321H, 316H, 347, 254Mo, 310s, etc. |

| Super duplex steel:s31803,s32205, s32750,s32760, 1.4462, 1.4410, 1.4501, etc. | |

| Nickel alloy:inconel600, inconel 625, inconel 718, incoloy 800, incoloy 825, C276,alloy 20, Monel 400, alloy 28 etc. | |

| OD | 1mm-2000mm , customized. |

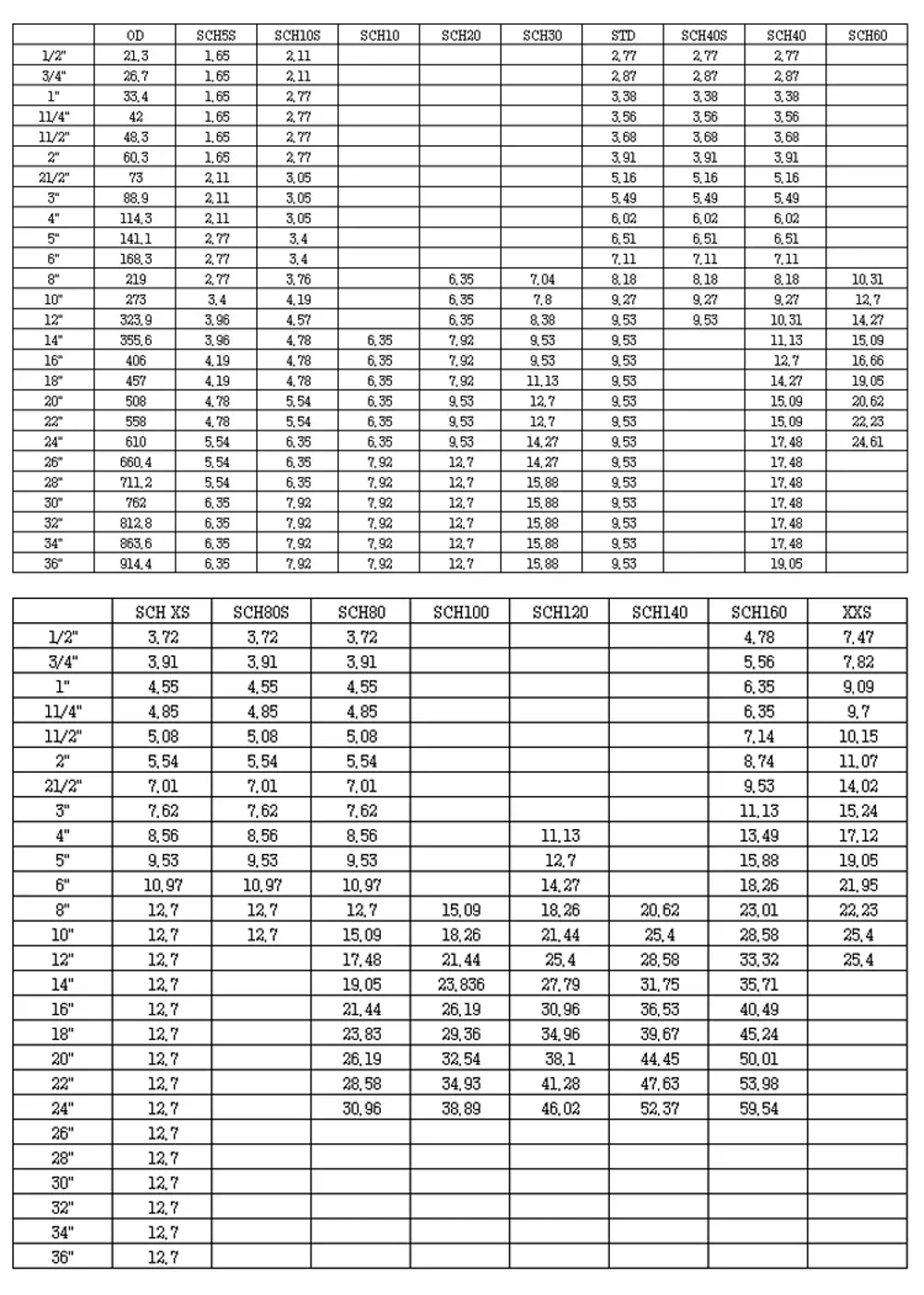

| Wall thickness | SCH5S SCH10S, SCH10, SCH20,SCH30, SCH40S, STD, SCH40, SCH80S, SCH80, XS, SCH60,SCH100, SCH120,SCH140,SCH160,XXS, customized , etc |

| Length | 5.8m, 6m, 11.8m, 12m, SRL, DRL, or as required |

| Surface | Annealing, pickling, polishing, bright, sand blast,hair line, brush, satin, snow sand, titanium, etc |

| Application | Stainless steel pipe widely used in petroleum,chemical industry,electric power, boiler,high temperature resistant, low temperature resistant, corrosion resistant., sour service, etc. |

| The size of the pipes can be made according to clients requirements. | |

| Contacts | If you have any questions, please feel free to contact me.we are sure your inquiry or requirements will get prompt attention. |

Material Characteristics

Incoloy 800 demonstrates outstanding performance in oxidizing and carburizing environments, maintaining excellent structural stability through continuous exposure to temperatures up to 1100°F (593°C).

The alloy's balanced composition provides remarkable resistance to oxidation, carburization, and sulfidation, while offering superior strength and workability compared to standard stainless steels.

Packaging & Shipping

All of our packaging can be customized according to requirements

Protective plastic end caps

Waterproof wrapping

Wooden crate packaging

Clear identification marking

Global shipping support

Inspection

All products undergo comprehensive testing including:

Ultrasonic examination

Eddy current testing

Mechanical property validation

Chemical analysis certification

Microstructure examination

Before delivery, our QC team will arrange NDT test and dimension inspection.

Also accept TPI(third party inspection).

Product description

We manufacture Incoloy Alluel 800 seamless pipes and tubes compliant with ASTM B407/ASME SB163 standards.

These nickel-iron-chromium alloy components deliver exceptional performance in high-temperature applications, featuring excellent resistance to oxidation, carburization, and sulfidation.

We provide complete technical support and customization services including special size requirements, heat treatment optimization, and application-specific testing protocols. Our engineering team ensures optimal material selection and performance for your specific operational requirements, backed by comprehensive material certification and traceability documentation.

Petrochemical Processing

Ideal for ethylene furnace tubes, reformer assemblies, and pyrolysis components in hydrocarbon processing equipment. Performs reliably in cracking furnace environments with exposure to steam and process gases.

Power Generation

Suitable for heat exchanger tubing, superheater supports, and steam generator components in conventional and nuclear power facilities. Maintains integrity in high-temperature steam environments.

Chemical Processing

Excellent performance in nitric acid production, vinyl chloride monomer manufacturing, and various chemical reactor systems. Resists stress corrosion cracking in chloride-containing environments.

Heat Treatment Industry

Widely used for radiant tubes, muffles, and retorts in industrial furnace applications. Demonstrates exceptional resistance to carburization and oxidation in direct-fired environments.

FAQ

1. What is 304 round stainless steel pipe seamless white steel pipe?

304 round stainless steel pipe seamless white steel pipe is a cylindrical pipe made of 304 grade stainless steel, seamless and with a white surface.

2. What is the difference between seamless steel pipe and welded steel pipe?

Seamless steel pipes are manufactured without any welds and have a smoother and more uniform surface. Welded steel pipe is made by welding two or more sections of steel together.

3. What are the benefits of using grade 304 stainless steel?

Grade 304 stainless steel is highly corrosion-resistant, making it suitable for a variety of applications. It also offers excellent strength and durability, good heat resistance, and is easy to clean and maintain.

4. What are the common uses of 304 round stainless steel pipe and seamless white steel pipe?

These pipes are commonly used in industries such as food processing, pharmaceutical, chemical, petrochemical, and construction. They can be used to transport fluids, gases and solids as well as in structural applications.

5. Can 304 round stainless steel pipe seamless white steel pipe be used for outdoor applications?

Yes, grade 304 stainless steel is suitable for outdoor applications as it resists corrosion caused by exposure to moisture, chemicals, and harsh weather conditions.

6. What is the maximum temperature that 304 round stainless steel pipe seamless white steel pipe can withstand?

Grade 304 stainless steel has a maximum operating temperature of approximately 870°C (1600°F), making it suitable for high temperature applications.

7. How to ensure the quality of 304 round stainless steel seamless white steel pipe?

The quality of these pipes is ensured through various tests and inspections, including chemical composition analysis, mechanical testing, dimensional inspection, and non-destructive testing methods such as ultrasonic testing.

8. Can the size and length of 304 round stainless steel seamless white steel pipe be customized?

Yes, these tubes can be customized to specific requirements in terms of size, length and even surface finish. Customization options are available to meet the diverse needs of different applications.

9. How should 304 round stainless steel seamless white steel pipes be stored?

To ensure proper storage, these tubes should be kept in a dry and clean environment, preferably indoors. They should be protected from moisture, chemicals and physical damage during storage.

10. Are there any certifications for 304 round stainless steel seamless white steel pipes?

Yes, reputable manufacturers can provide certifications such as Material Test Reports (MTR), Factory Test Certificates (MTC) and Certificates of Compliance to ensure product quality and traceability.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

Metal Incoloy 825 Nickel Alloy Pipe Seamless Fo...

-

factory directly sale ERW Iron Pipe 6 Meter Wel...

-

Pipe Stainless Steel Aisi 304l Seamless Thickne...

-

Inconel 718 601 625 Monel K500 32750 Incoloy 82...

-

ASTM AMS UNS 600 602 625 718 5540 B168 N06025 H...

-

C276 400 600 601 625 718 725 750 800 825SS Seri...