ERW EN10210 S355 Carbon Steel Pipe

We specialize in the manufacturing of high-performance ERW (Electric Resistance Welded) carbon steel pipes compliant with EN10210 standards, specifically engineered for demanding gas and oil pipeline applications and liquid transmission systems. Our S355 grade steel pipes represent the pinnacle of European engineering standards, combining superior mechanical properties with exceptional durability for critical infrastructure projects. These pipes are designed to meet the rigorous requirements of energy transportation, featuring optimized wall thickness, precise dimensional control, and enhanced weld integrity for safe and efficient fluid transmission over extended distances and challenging environmental conditions.

Product parameters

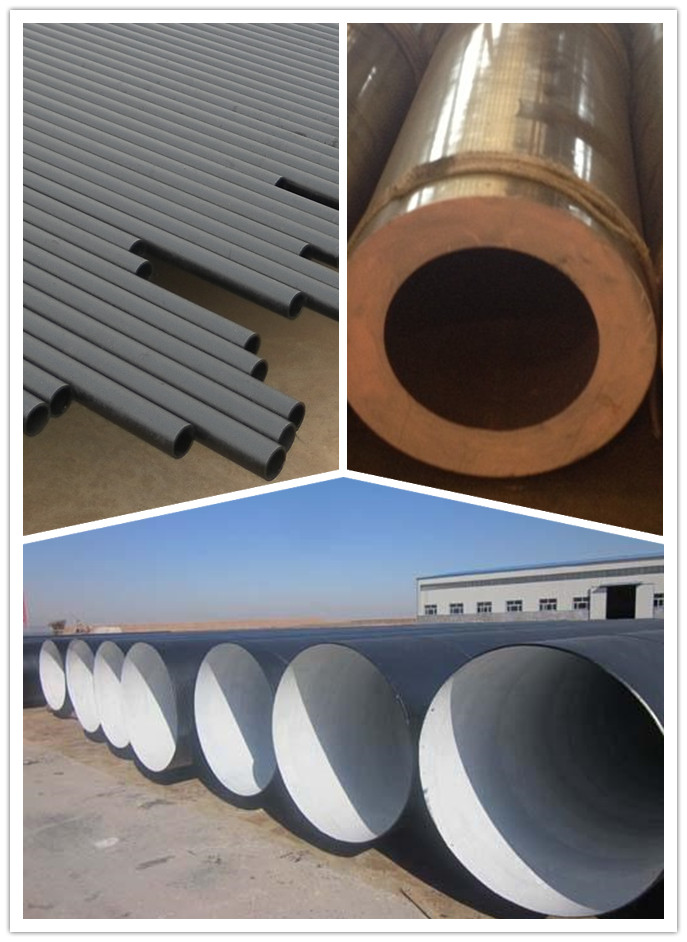

| Product name | seamless pipes, ERW pipe, DSAW pipes. |

| Standard | ASME B36.10M, API 5L, ASTM A312, ASTM A213. ASTM A269, etc |

| Material | Carbon steel: A106 GR B, A53 GR B,ASTM A333 GR 6 etc. |

| Cr-Mo alloy: A335 P11, A335 P22, A335 P12, A335 P5, A335 P9, A335 P91,etc | |

| Pipeline steel: API 5L GR B, API 5L X42, API 5L X46, API 5L X56, API 5L X60, API 5L X65, API 5L X70,etc | |

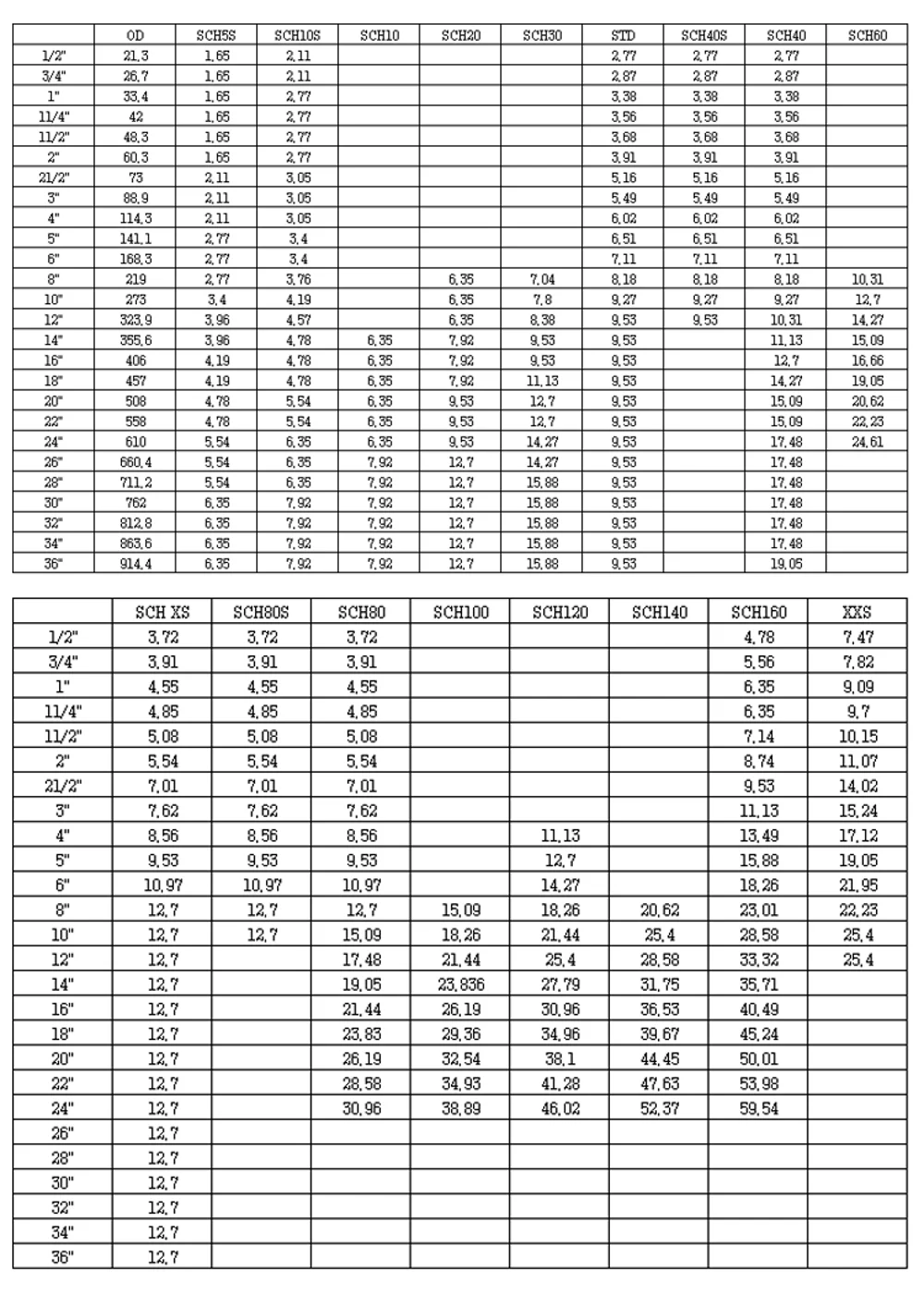

| OD | 3/8" -100" , customized |

| Wall thickness | SCH5S SCH10S, SCH10, SCH20,SCH30, SCH40S, STD, SCH40, SCH80S, SCH80,

XS, SCH60,SCH100, SCH120,SCH140,SCH160,XXS, customized , etc |

| Length | 5.8m, 6m, 11.8m, 12m, or as required |

| Surface | Black painting, 3PE coating, other special coating, etc |

| Application | Stainless steel pipe widely used in petroleum,chemical industry,electric power, boiler,high temperature resistant,

low temperature resistant, corrosion resistant., sour service, etc. |

| The size of the pipes can be made according to clients requirements. | |

| Contacts | If you have any questions, please feel free to contact me.we are sure your inquiry or requirements will get prompt attention. |

Material Processing Characteristics

Hot Forming: Pipes formed from hot-rolled steel strips

Normalized Condition: Delivery in normalized condition for optimal properties

Microstructure: Fine-grained ferrite-pearlite structure

Surface Quality: Scale-free or lightly sealed surface per EN10210 requirements

Non-Destructive Testing

Ultrasonic Testing: 100% weld seam examination per EN10246-3

Eddy Current Testing: Complete pipe body testing for surface defects

Magnetic Particle Testing: For weld zone and critical areas

Hydrostatic Testing: Minimum test pressure = 2 × design pressure

Visual Inspection: 100% surface examination per EN10246-1

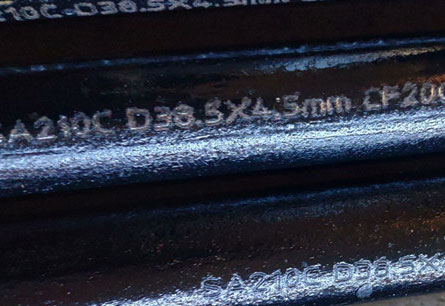

Marking

Printed or Curved marking on request. OEM is accepted.

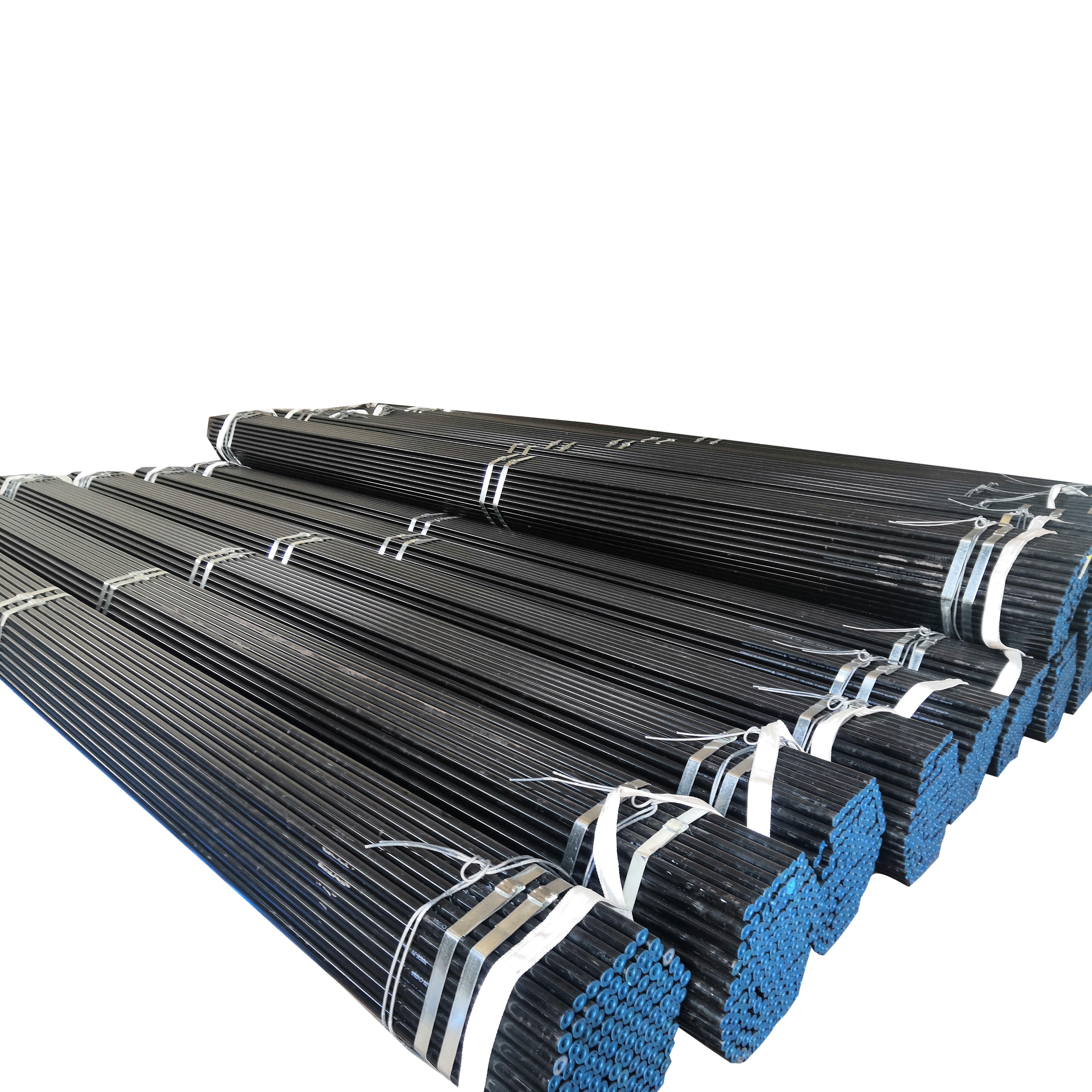

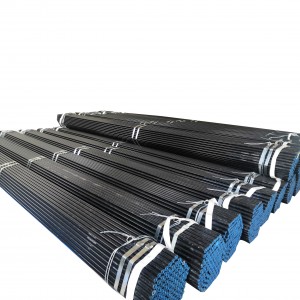

Packaging & Shipping

Protective Packaging

Individual Protection: Plastic end caps and protective wrapping

Bundle Configuration: Hexagonal bundles with steel strapping

Weather Protection: Waterproof wrapping for outdoor storage

Identification: Color coding and permanent marking

Shipping and Handling

Container Loading: Optimized loading for 20ft and 40ft containers

Break Bulk Shipping: Vessel loading up to 15,000 metric tons

Documentation: Complete shipping and customs documentation

Insurance: Comprehensive cargo insurance available

Product description

Our ERW EN10210 S355 carbon steel pipes represent the convergence of European engineering excellence, advanced manufacturing technology, and practical application expertise in gas, oil, and liquid transmission engineering. These pipes are engineered to deliver uncompromising performance in the most demanding pipeline applications, combining the mechanical reliability of S355 grade steel with the precision manufacturing of modern ERW technology.

The comprehensive quality assurance program, rigorous testing protocols, and complete certification ensure that every pipe meets the highest standards of safety, reliability, and performance. Whether for cross-country gas transmission, offshore oil pipelines, or critical water supply systems, these pipes provide the foundation for safe and efficient fluid transportation infrastructure.

FAQ

1. What is ASTM A312?

ASTM A312 is a specification for seamless, welded, and heavy cold worked austenitic stainless steel pipe for use in high temperature and generally corrosive environments.

2. What is black steel pipe?

Black steel pipe is a non-galvanized steel pipe with a dark iron oxide coating. The coating enhances corrosion resistance and gives the pipe its characteristic black appearance.

3. What are the benefits of using hot-rolled pipes?

Hot-rolled tubes offer several benefits, including improved formability, superior surface finish, improved dimensional accuracy and enhanced mechanical properties. They are typically used in applications that require strong, durable, and precision-engineered pipes.

4. Why are carbon steel pipes favored in various industries?

Carbon steel pipes are popular in various industries because of their strength, affordability, and versatility. It is widely used in oil and gas exploration, chemical processing, power generation, automobiles, construction and many other fields.

5. How is the manufacturing process of black steel pipe different from other pipes?

The manufacture of black steel pipes involves specific heating and cooling processes. The steel is heated to high temperatures, rolled into tubes, and then rapidly cooled to form a stable layer of iron oxide that gives the tube its black color.

6. What are the applications of ASTM A312 black steel pipe?

ASTM A312 black steel pipe is used in a variety of industries, including oil and gas, petrochemicals, water treatment, piping, HVAC systems, structural supports, and general manufacturing. It is commonly used to transport fluids and gases under high pressure and high temperature conditions.

7. Can black steel pipes be used outdoors?

Yes, black steel pipe is available for outdoor applications. The iron oxide coating provides excellent protection against corrosion, making it suitable for a wide range of environmental conditions. However, additional protective coatings may be required in extremely corrosive environments.

8. Are hot rolled tubes suitable for precision engineering applications?

Yes, hot rolled pipes are widely used in precision engineering applications. Its improved dimensional accuracy and superior surface finish make it ideal for manufacturing high-precision components, machinery and structures requiring tight tolerances.

9. What are the advantages of carbon steel pipes compared with other materials?

Carbon steel pipes offer several advantages, including high tensile strength, excellent wear resistance, good machinability and ease of welding. It is also cost-effective and available in a variety of sizes and specifications.

10. Is ASTM A312 black steel pipe suitable for high temperature applications?

Yes, ASTM A312 black steel pipe is specifically designed for high temperature applications. They have excellent heat resistance and are suitable for conveying steam, hot water and other high temperature fluids.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.