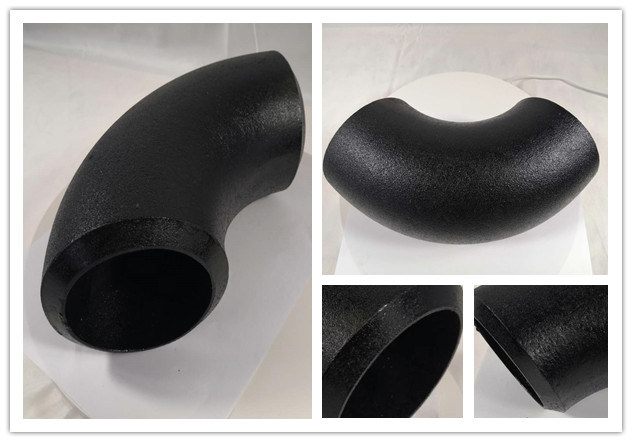

90 degree elbow tee reducer steel Butt weld pipe fitting elbow

Carbon steel butt weld pipe fittings—including 90-degree elbows, tees, and reducers—form the essential skeletal framework for directing, branching, and modifying fluid flow in industrial piping systems. Manufactured from robust ASTM A234-grade carbon steel, these fittings are engineered for permanent, leak-free connections through butt welding, offering superior strength and integrity compared to threaded or socket weld alternatives.

These components are precision-formed to meet ASME B16.9 dimensional standards, ensuring perfect alignment and fit-up with matching schedule pipes. The 90° elbow facilitates directional change with minimal pressure loss, the tee allows for branch connections, and the reducer manages pipe diameter transitions. Designed for seamless integration into high-pressure and high-temperature systems in sectors like oil & gas, power generation, and chemical processing, they provide a reliable, maintenance-free solution for constructing durable and efficient piping networks.

PRODUCT PARAMETERS

| Product Name | Pipe elbow |

| Size | 1/2"-36" seamless elbow(SMLS elbow), 26"-110" welded with seam. Biggest outside diameter can be 4000mm |

| Standard | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Degree | 30° 45° 60° 90° 180°,etc |

| Radius | LR/long radius/R=1.5D,SR/Short radius/R=1D |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 , 12crmov, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

PIPE FITTINGS

Butt welded pipe fittings includes steel pipe elbow, steel pipe tee, steel pipe reduer, steel pipe cap. All those butt welding pipe fittings, we can supply together, we have more 20 years production experiences.

If you are also interested other fittings, please click followed LINK to check details.

PIPE TEE PIPE REDUCER PIPE CAP PIPE BEND FORGED FITTINGS

BUTT WELDED PIPE ELBOW

Steel pipe elbow is a key parts in a piping system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

For industrial pipe elbow, the connectin end type is butt weld, according to ANSI B16.25. Butt welded can described butt welding, buttweld, bevel end. BW

ELBOW TYPE

Material & Manufacturing: Fittings are fabricated from ASTM A234 WPB (standard carbon steel) or other alloy grades (WP5, WP11, etc.) for high-temperature service. They are produced through hot forming (forging or induction bending) or cold forming processes, followed by heat treatment (normalizing) to relieve stresses and restore mechanical properties. This ensures uniform grain structure and enhanced durability.

Precision Engineering: Critical dimensions—such as center-to-end (elbow), center-to-face (tee), and overall length (reducer)—are machined to tight tolerances per ASME B16.9. The inside and outside surfaces are smooth to minimize turbulence and erosion. All weld ends are precision-beveled (37.5° ± 2.5°) with a consistent land to ensure full penetration during welding and optimal joint strength.

Design Variants:

90° Elbow: Available in Long Radius (LR, 1.5D bend radius) for smoother flow and lower pressure drop, and Short Radius (SR, 1D bend radius) for space-constrained installations.

Tee: Equal Tees have the same branch and run sizes; Reducing Tees feature a smaller branch size, allowing for flow division or equipment connection.

Reducer: Concentric Reducers maintain the centerline, used in vertical lines. Eccentric Reducers have an offset centerline, crucial for horizontal pump suction lines to avoid air pocket formation.

Quality Marking: Each fitting is permanently marked with the material grade (e.g., A234 WPB), size, schedule, manufacturer's logo, and heat number (for traceability), in compliance with ASTM A960.

ELBOW SURFACE

Sand Blast

After hot forming, we arrange sand blast to make the surface to be clean and smooth.

After Sand blast, to avoid get rust, should do black painting or anti-rust oil, Hot dip galvanized (HDG) , epoxy, 3PE, vanished surface, etc. That is depend on customer's request.

HEAT TREATMENT

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO.

Product DETAILED

90° Elbow: Long Radius (LR - 1.5D) and Short Radius (SR - 1D) center-to-face dimensions.

Tee: Straight (Equal) and Reducing configurations.

Reducer: Concentric (aligned centers) and Eccentric (offset centers, commonly flat-on-top for pump suction lines).

End Preparation: Beveled ends for welding, typically with a 37.5° bevel and a 1.6mm land.

Surface Treatment: Black (mill scale), sandblasted, or painted (primer) as required.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. MT, UT,X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate

PACKAGING& SHIPPING

Packaging: Fittings are carefully packaged to prevent damage during transit. Standard protection includes coating with anti-rust oil or VCI (Vapor Corrosion Inhibitor) and individual wrapping in plastic or waterproof paper. The beveled ends are protected with plastic or steel caps to preserve the welding surface. For bulk orders, fittings are palletized and secured with steel straps, then covered with shrink wrap. Large-diameter or heavy fittings are crated in custom wooden boxes with internal bracing.

Marking & Documentation: Each package is labeled with the product description, size, material, quantity, and PO number. Shipping documents include a detailed packing list, commercial invoice, and material certificates.

Shipping: We offer flexible shipping solutions via sea container (FCL/LCL), air freight, or land transportation. For project cargo, we coordinate with specialized freight forwarders to handle oversized fittings, ensuring safe and timely delivery to global destinations.

Wide-Ranging Industrial Applications: These butt weld fittings are fundamental components across numerous sectors:

- Oil & Gas: Onshore/offshore pipelines, refinery process piping, wellhead manifolds, and compressor stations.

- Power Generation: Main steam and feedwater lines in thermal plants, cooling water systems, and fuel gas piping.

- Chemical & Petrochemical Plants: Reactor feed lines, distillation column piping, heat exchanger connections, and corrosive fluid handling systems.

- Water Treatment & Distribution: Pump discharge headers, filter piping, and large-diameter transmission mains.

- Shipbuilding & Marine Engineering: Engine room piping, ballast systems, and cargo transfer lines.

Our Manufacturing & Supply Chain Advantages:

- Complete Range & Availability: We stock a comprehensive inventory of standard sizes and schedules in carbon steel, ensuring quick delivery for routine projects and maintenance shutdowns.

- Technical Expertise & Customization: Our engineering team supports non-standard requirements, including special sizes (beyond 48"), unique wall thicknesses, special end preparations, or fittings made to customer-specific dimensional standards (e.g., JIS, DIN).

- Quality Assurance from Start to Finish: We implement stringent quality control at every stage—from raw material inspection to final dimensional verification—ensuring each fitting meets the highest standards of integrity and performance.

- Cost-Effective Global Logistics: As a direct manufacturer with extensive export experience, we optimize packaging and shipping routes to provide reliable, cost-effective delivery to job sites worldwide, supported by complete documentation for seamless customs clearance.

- Long-term Reliability: Our fittings are manufactured for durability and long service life, reducing maintenance costs and downtime for our clients, making them a trusted choice for critical infrastructure projects globally.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

ANSI b16.9 36 inch schedule 40 Butt Weld carbon...

-

SUS 304 321 316 180 Degree Stainless steel pipe...

-

factory DN25 25A sch160 90 degree elbow pipe fi...

-

A234 WP22 WP11 WP5 WP91 WP9 Alloy Steel Elbow

-

A234WPB black seamless steel pipe fitting unequ...

-

carbon steel concentric reducer astm a105 Black...