PRODUCT PARAMETERS

| Product Name | Stub end |

| Size | 1/2"-24" seamless, 26"-60" welded |

| Standard | ANSI B16.9, MSS SP 43, EN1092-1, customized, and etc. |

| Wall thickness | SCH5S, SCH10, SCH10S, STD,XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS ,customized and etc. |

| Type | Long and short |

| End | Bevel end/BE/buttweld |

| Surface | pickled, sand rolling |

| Material | Stainless steel: A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276,Monel400, Alloy20 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

SHORT/LONG PATTERN STUB ENDS (ASA/MSS)

Stub ends are available in two different patterns:

- the short pattern, called MSS-A stub ends

- the long pattern, called ASA-A stub ends (or ANSI length stub end)

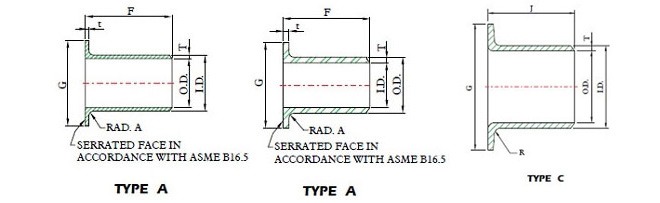

STUB END TYPES

Stub ends are available in three different types, named “Type A”, “Type B” and “Type C”:

- The first type (A) is manufactured and machined to match standard lap joint backing flange (the two products have to be used in combination). The mating surfaces have an identical profile to permit a smooth loading of the flare face

- Stub ends type B are have to be used with standard slip-on flanges

- Type C stub ends can be used either with lap joint or slip-on flanges and are manufactured from pipes

BENEFITS OF LAP JOINT STUB ENDS

It shall be noted that stud ends are becoming popular also in high-pressure applications (whereas they were used for low-pressure applications only in the past).

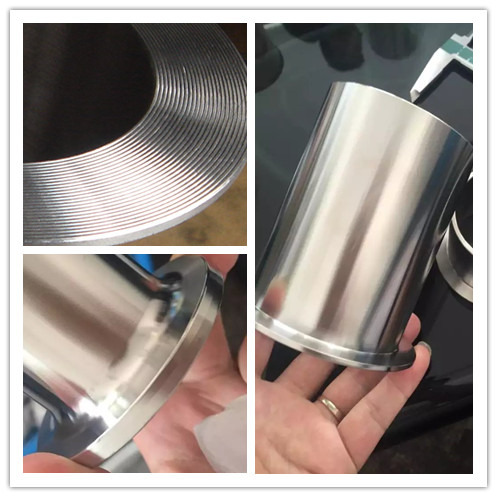

DETALED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Without lamination and cracks

3. Without any weld repairs

4. Surface treatment can be pickled or CNC fine machined. For sure, the price is different. For your reference, pickled surface is cheaper.

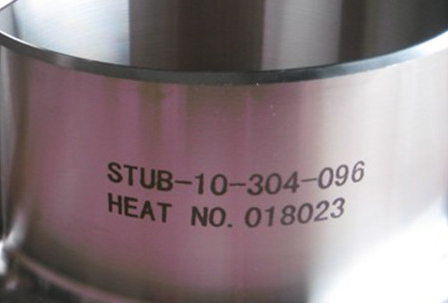

MARKING

Various marking work can be on your request. We accept mark your LOGO.

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. PT, UT,X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate, NACE

PACKAGING & SHIPPING

1. Packed by plywood case or plywood pallet as per

2. we will put packing list on each package

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free

INSPECTION

1. Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request

3. PMI

4. PT, UT,X-ray test

5. Accept Third party inspection

6. Supply MTC, EN10204 3.1/3.2 certificate, NACE

-

DN50 50A STD 90 degree elbow pipe fitting long ...

-

Stainless steel long bend1d 1.5d 3d 5d radius 3...

-

sch80 ss316 stainless steel Butt Weld Eccentri...

-

SUS 304 321 316 180 Degree Stainless steel pipe...

-

Asme b16.9 schedule 80 steel pipe fittings tee ...

-

3050mm API 5L X70 WPHY70 Welded pipe fitting elbow