PRODUCT PARAMETERS

| Product Name | Pipe reducer |

| Size | 1/2"-24" seamless, 26"-110" welded |

| Standard | ANSI B16.9, EN10253-2, DIN2616, GOST17378, JIS B2313, MSS SP 75, etc. |

| Wall thickness | SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40,SCH,60, SCH80, SCH160, XXS ,customized and etc. |

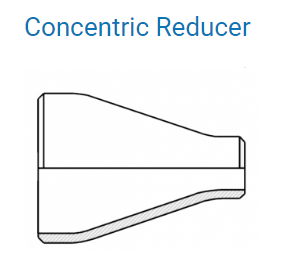

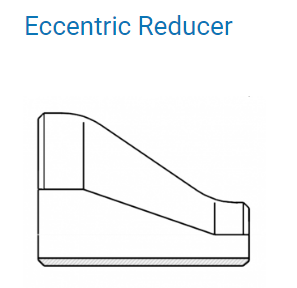

| Type | Concentric or eccentric |

| Process | Seamless or welded with seam |

| End | Bevel end/BE/buttweld |

| Surface | pickled, sand rolling, polished, mirror polishing and etc. |

| Material | Stainless steel: A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. |

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276,Monel400, Alloy20 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality. |

APPLICATIONS OF STEEL PIPE REDUCER

The usage of a steel reducer is carried out in the chemical factories and power plants. It makes the piping system reliable and compact. It safeguards the piping system from any kind of adverse impact or thermal deformation. When it is on the pressure circle, it prevents from any type of leakage and is easy to install. The nickel or chrome coated reducers extends the product life, useful for high vapor lines, and prevents corrosion.

REDUCER TYPES

Concentric reducers are widely used while eccentric reducers are applied to maintain the top and bottom pipe level. Eccentric Reducers also avoids trapping of air inside the pipe, and Concentric Reducer removes noise pollution.

MANUFACTURING PROCESS OF STEEL PIPE REDUCER

There are versatile manufacturing processes for the reducers. These are made of welded pipes with the required filling material. However, EFW and ERW pipes cannot use the reducer. To manufacture forged parts, different kinds of methods are used including cold and hot forming processes.

DETAILED PHOTOS

1. Bevel end as per ANSI B16.25.

2. Rough polish first before sand rolling, then the surface will be much smooth.

3. Without lamination and cracks.

4. Without any weld repairs.

5. Surface treatment can be pickled, sand rolling, matt finished, mirror polished. For sure, the price is different. For your reference, sand rolling surface is the most popular. The price for sand roll is suitable for most clients.

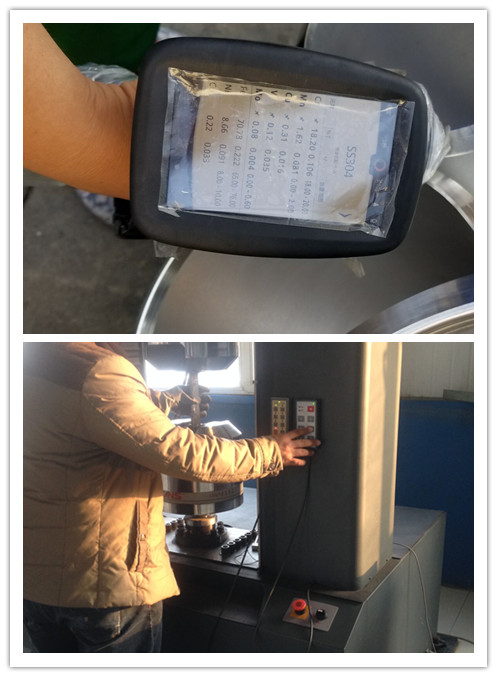

NSPECTION

1.Dimension measurements, all within standard tolerance.

2. Thickness tolerance:+/-12.5% , or on your request.

3. PMI

4. PT, UT,X-ray test.

5.Accept Third party inspection.

6.Supply MTC, EN10204 3.1/3.2 certificate, NACE

7.ASTM A262 practice E

PACKAGING & SHIPPING

1. Packed by plywood case or plywood pallet.

2. we will put packing list on each package.

3. we will put shipping markings on each package. Markings words are on your request.

4. All wood package materials are fumigation free.

FAQ

1. What is SCH80 SS316 stainless steel butt welding eccentric reducer?

SCH80 SS316 Stainless Steel Butt Weld Eccentric Reducer is a pipe fitting used in piping systems to reduce the size of pipes at connection points. It has a larger diameter on one end and a smaller diameter on the other, allowing for a transition between two different pipe sizes.

2. What are the benefits of using SCH80 SS316 stainless steel butt welded eccentric reducer?

There are several advantages to using SCH80 SS316 stainless steel butt welded eccentric reducers. First, it allows for a smooth transition between different pipe sizes, ensuring efficient flow and reducing pressure drop. Secondly, the use of stainless steel ensures excellent corrosion resistance and durability, making it suitable for a variety of applications. Finally, the butt weld connection provides a strong and leak-proof joint.

3. What is the difference between eccentric reducer and concentric reducer?

The main difference between eccentric and concentric reducers is their shape and purpose. One end of the eccentric reducer deviates from the centerline of the pipe, resulting in an eccentric transition. This type of reducer is used when it is necessary to maintain drainage or ventilation connections or to avoid trapped air or gas in the system. In contrast, both ends of a concentric reducer are aligned with the centerline, providing a symmetrical transition between pipe sizes.

4.What is SCH80? Why is it important?

SCH80 refers to the thickness of the pipe or fitting, in this case specifically a stainless steel butt weld eccentric reducer. It is a standard code used to express specific wall thicknesses for pipes and fittings. The SCH80 designation indicates that the material has thicker walls compared to SCH40, providing higher mechanical strength and pressure ratings for demanding applications.

5. Can SCH80 SS316 stainless steel butt welding eccentric reducer be used with different materials?

Yes, SCH80 SS316 Stainless Steel Butt Weld Eccentric Reducers can be used with different materials, but it is important to consider their compatibility. Stainless steel is generally compatible with a variety of materials, but it is recommended to consult an industry professional to ensure compatibility, considering factors such as temperature, pressure and chemical resistance.

6. How to install SCH80 SS316 stainless steel butt welding eccentric reducer?

The installation process for the SCH80 SS316 Stainless Steel Butt Weld Eccentric Reducer involves cutting the pipe at the desired location, ensuring a clean and square cut. The reducer should then be aligned with both pipe ends and the welding process should be performed in accordance with industry standards and guidelines. Proper alignment and proper welding techniques must be ensured to create a strong and leak-free joint.

7. What are the common applications of SCH80 SS316 stainless steel butt welded eccentric reducer?

SCH80 SS316 Stainless Steel Butt Weld Eccentric Reducers are commonly used in a variety of industries and applications. They are frequently found in chemical processing plants, oil and gas refineries, the pharmaceutical industry, food processing plants and water treatment facilities. These reducers are suitable for applications requiring durability, corrosion resistance and efficient fluid flow.

8. What certifications or standards should SCH80 SS316 stainless steel butt welded eccentric reducer meet?

When selecting SCH80 SS316 stainless steel butt weld eccentric reducer, it is important to ensure that it complies with relevant certifications and standards. Commonly used standards include ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), and ANSI (American National Standards Institute). Additionally, quality management certifications such as ISO 9001:2015 may be required.

9. Can SCH80 SS316 stainless steel butt-welded eccentric reducer be customized?

Yes, SCH80 SS316 Stainless Steel Butt Weld Eccentric Reducers can be customized to meet specific project requirements. Customization options may include different end diameters, lengths, or modifications to accommodate unique pipe configurations. It is recommended to consult with the manufacturer or supplier to discuss customization options and requirements.

10. Does SCH80 SS316 stainless steel butt welded eccentric reducer need maintenance?

SCH80 SS316 Stainless Steel Butt Weld Eccentric Reducers typically require minimal maintenance due to their high corrosion resistance and durability. However, it is recommended to check the reducer regularly for signs of damage or leaks. Additionally, regular inspections of the entire piping system and appropriate maintenance measures, in accordance with industry guidelines, are critical to ensuring optimal performance and longevity.