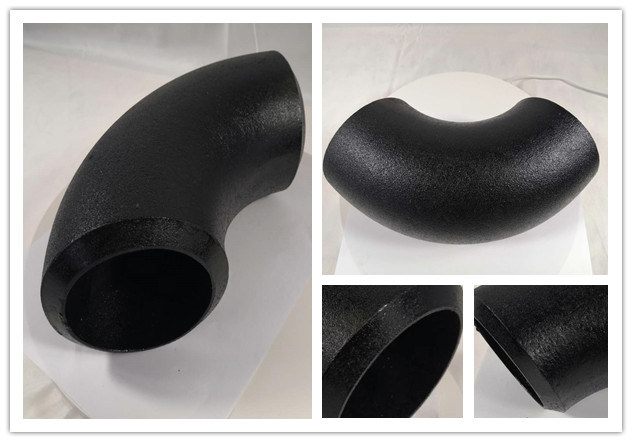

DN50 2" STD 90° Long Radius Elbow

The DN50 2" STD 90° Long Radius Elbow in ASTM A860 WPHY 60 is a precision-engineered piping component designed for high-strength applications in demanding industrial services. Manufactured in strict compliance with ASME B16.9 dimensional standards and utilizing ASTM A860 WPHY 60 high-yield carbon steel, this seamless long radius elbow provides exceptional durability and performance for high-pressure and low-temperature applications, particularly in the oil, gas, and petrochemical industries.

The 1.5D bend radius ensures smooth fluid flow with minimal pressure drop and turbulence, while the seamless construction guarantees superior pressure integrity compared to welded alternatives. The WPHY 60 material offers enhanced yield strength (minimum 415 MPa / 60 ksi) and excellent notch toughness at low temperatures, making this elbow ideal for services requiring reliable performance under challenging conditions. Its precision-machined weld bevels facilitate high-quality field welding, ensuring leak-free connections in critical piping systems.

PRODUCT PARAMETERS

| Product Name | Pipe elbow |

| Size | 1/2"-36" seamless elbow(SMLS elbow), 26"-110" welded with seam. Biggest outside diameter can be 4000mm |

| Standard | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Degree | 30° 45° 60° 90° 180°,etc |

| Radius | LR/long radius/R=1.5D,SR/Short radius/R=1D |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 , 12crmov, etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

PIPE FITTINGS

Butt welded pipe fittings includes steel pipe elbow, steel pipe tee, steel pipe reduer, steel pipe cap. All those butt welding pipe fittings, we can supply together, we have more 20 years production experiences.

If you are also interested other fittings, please click followed LINK to check details.

PIPE TEE PIPE REDUCER PIPE CAP PIPE BEND FORGED FITTINGS

BUTT WELDED PIPE ELBOW

Steel pipe elbow is a key parts in a piping system for to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

For industrial pipe elbow, the connectin end type is butt weld, according to ANSI B16.25. Butt welded can described butt welding, buttweld, bevel end. BW

ELBOW TYPE

Elbow could be ranged from direction angle, connection types, length and radius, material types.

Classified by Direction Angle

As we know, according to fluid direction of the pipelines, elbow can be divided into different degrees, such as 45 degree, 90 degree,180 degree, which are most common degrees. Also there has 60 degree and 120 degree, for some special pipelines.

For 90 degree elbow, also described 90d elbow, or 90 deg elbow.

What is Elbow Radius

The elbow radius mean curvature radius. If the radius is the same as pipe diameter, it called short radius elbow, also called SR elbow, normally for low pressure and low speed pipelines.

If the radius is larger than pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high pressure and high flow rate pipelines.

If radius more than 1.5D, always named bend. elbow bend pipe fittings. Such as 2d elbow, 2d bend, 3d elbow, 3d bend, etc.

Classification by Material

Carbon steel, also called mild steel or black steel. Such as ASTM A234 WPB

Looking for stainless steel elbows, please click this link to find more details: STAINLESS STEEL ELBOWS

Shape Type

Can be equal elbow or Reducing elbow

ELBOW SURFACE

Sand Blast

After hot forming, we arrange sand blast to make the surface to be clean and smooth.

After Sand blast, to avoid get rust, should do black painting or anti-rust oil, Hot dip galvanized (HDG) , epoxy, 3PE, vanished surface, etc. That is depend on customer's request.

HEAT TREATMENT

1. Keep sample raw material to trace.

2. Arrange heat treatment as per standard strictly.

MARKING

Various marking work, can be curved, painting, lable. Or on your request. We accept to mark your LOGO.

Product Detail

Material Specification – ASTM A860 WPHY 60:

This elbow is manufactured from seamless pipe conforming to ASTM A860 WPHY 60, a high-strength carbon steel specifically designed for high-yield strength applications. Key material characteristics include:

Minimum Yield Strength: 415 MPa (60,000 psi)

Minimum Tensile Strength: 520-760 MPa (75,000-110,000 psi)

Chemical Composition: Controlled carbon equivalent (CE) for enhanced weldability

Heat Treatment: Typically normalized to achieve specified mechanical properties and grain structure

Seamless Manufacturing Process:

Utilizing advanced hot forming technology, the elbow is manufactured from seamless pipe through controlled heating and bending processes. This method:

Preserves Material Integrity: No longitudinal weld seam eliminates potential weak points

Ensures Uniformity: Consistent wall thickness throughout the bend

Optimizes Grain Flow: The hot working process aligns the grain structure to follow the elbow contour

Maintains Dimensions: Precision tooling ensures compliance with ASME B16.9 tolerances

Precision Dimensions & Tolerances:

Center-to-End: 76 mm (±1.5 mm tolerance)

Wall Thickness: Maintained within +12.5%/-10% of nominal thickness

Out-of-Roundness: Maximum 1% of nominal outside diameter

Bevel Accuracy: 37.5° ± 2.5° with consistent land preparation

Surface Finish: Smooth internal surface to minimize flow resistance

Quality Features:

Full Traceability: Heat number tracking from steel production through final inspection

Marking Compliance: Permanent stamping per ASTM A960 requirements

Surface Protection: Temporary rust preventive applied to machined surfaces

Certification Ready: Complete documentation package available

INSPECTION

Material Certification & Verification:

Mill Test Certificate: EN 10204 3.1 certificate provided with each batch

Chemical Analysis: Verification of C, Mn, Si, P, S, and micro-alloying elements

Mechanical Testing: Tensile, yield strength, and elongation confirmation

Charpy Impact Testing: Mandatory testing at -46°C (-50°F) for WPHY 60 material

PACKAGING& SHIPPING

Protective Packaging:

Each elbow is coated with a temporary anti-corrosion oil or VCI (Vapor Corrosion Inhibitor) compound to prevent rust during transit. The weld bevel ends are protected with plastic or metal caps to prevent damage to the critical welding surfaces. Individual elbows are then wrapped in waterproof plastic or VCI paper.

Bulk Packaging:

For quantity orders, elbows are bundled using steel straps on wooden pallets. Between each layer, protective cardboard or foam sheets are inserted to prevent scratching and abrasion. The entire pallet is then wrapped in heavy-duty polyethylene shrink film for weather protection.

Application

Oil & Gas Transmission:

Gathering lines, pipeline laterals, and station piping

Petrochemical Plants:

Process piping in refineries and chemical facilities

Power Generation:

High-pressure feedwater and steam lines

Industrial Processing:

High-pressure fluid handling systems

Low-Temperature Services: Applications requiring enhanced impact resistance

Our DN50 WPHY 60 elbows represent more than just a piping component – they are engineered solutions for demanding industrial applications. With our commitment to quality, technical expertise, and customer service, we provide not only products but also the support and assurance needed for successful project implementation and long-term operational reliability.

Pipe fittings are crucial components in the piping system, used for connection, redirection, diversion, size change, sealing or controlling the flow of fluids. They are widely applied in fields such as construction, industry, energy and municipal services.

Key Functions: It can perform functions such as connecting pipes, changing flow direction, dividing and merging flows, adjusting pipe diameters, sealing pipes, controlling and regulating.

Application Scope:

- Building water supply and drainage: PVC elbows and PPR tris are used for water pipe networks.

- Industrial pipelines: Stainless steel flanges and alloy steel elbows are used to transport chemical media.

- Energy transportation: High-pressure steel pipe fittings are used in oil and gas pipelines.

- HVAC (Heating, Ventilation, and Air Conditioning): Copper pipe fittings are used to connect refrigerant pipelines, and flexible joints are used for vibration reduction.

- Agricultural irrigation: Quick connectors facilitate the assembly and disassembly of sprinkler irrigation systems.

-

factory DN25 25A sch160 90 degree elbow pipe fi...

-

Asme b16.9 schedule 80 steel pipe fittings tee ...

-

ANSI B16.9 butt weld Pipe Fitting carbon steel ...

-

DN50 50A sch10 90 elbow pipe fitting LR seamles...

-

Pipe Fittings Stainless Steel White Steel Forge...

-

DN500 20 inch Alloy steel A234 WP22 seamless 90...